Electro-tools and machines Chapter overview ... - EN / Hahn+Kolb

Electro-tools and machines Chapter overview ... - EN / Hahn+Kolb

Electro-tools and machines Chapter overview ... - EN / Hahn+Kolb

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

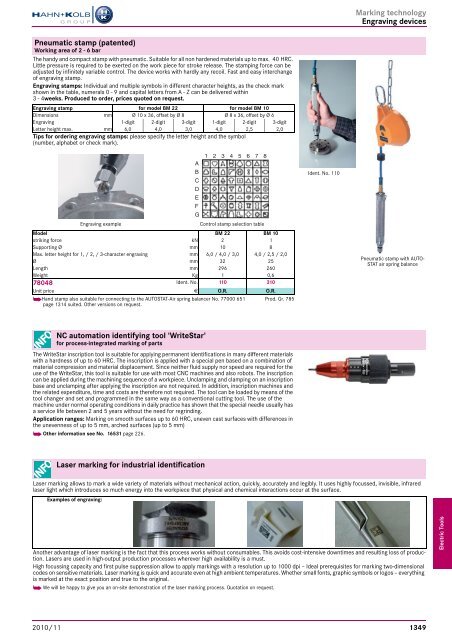

Marking technologyEngraving devicesContinued next pagePneumatic stamp (patented)Working area of 2 - 6 barThe h<strong>and</strong>y <strong>and</strong> compact stamp with pneumatic. Suitable for all non hardened materials up to max. 40 HRC.Little pressure is required to be exerted on the work piece for stroke release. The stamping force can beadjusted by infinitely variable control. The device works with hardly any recoil. Fast <strong>and</strong> easy interchangeof engraving stamp.Engraving stamps: Individual <strong>and</strong> multiple symbols in different character heights, as the check markshown in the table, numerals 0 - 9 <strong>and</strong> capital letters from A - Z can be delivered within3 - 4weeks. Produced to order, prices quoted on request.Engraving stamp for model BM 22 for model BM 10Dimensions mm Ø 10 x 36, offset by Ø 8 Ø 8 x 36, offset by Ø 6Engraving 1-digit 2-digit 3-digit 1-digit 2-digit 3-digitLetter height max. mm 6,0 4,0 3,0 4,0 2,5 2,0Tips for ordering engraving stamps: please specify the letter height <strong>and</strong> the symbol(number, alphabet or check mark).Ident. No. 110Engraving exampleControl stamp selection tableModel BM 22 BM 10striking force kN 2 1Supporting Ø mm 10 8Max. letter height for 1, / 2, / 3-character engraving mm 6,0 / 4,0 / 3,0 4,0 / 2,5 / 2,0Ø mm 32 25Length mm 296 260Weight Kg 1 0,678048 Ident. No. 110 310Unit price E O.R. O.R.hH<strong>and</strong> stamp also suitable for connecting to the AUTOSTAT-Air spring balancer No. 77000 651 Prod. Gr. 785page 1314 suited. Other versions on request.Pneumatic stamp with AUTO-STAT air spring balanceContinued next pageNC automation identifying tool 'WriteStar'for process-integrated marking of partsThe WriteStar inscription tool is suitable for applying permanent identifications in many different materialswith a hardness of up to 60 HRC. The inscription is applied with a special pen based on a combination ofmaterial compression <strong>and</strong> material displacement. Since neither fluid supply nor speed are required for theuse of the WriteStar, this tool is suitable for use with most CNC <strong>machines</strong> <strong>and</strong> also robots. The inscriptioncan be applied during the machining sequence of a workpiece. Unclamping <strong>and</strong> clamping on an inscriptionbase <strong>and</strong> unclamping after applying the inscription are not required. In addition, inscription <strong>machines</strong> <strong>and</strong>the related expenditure, time <strong>and</strong> costs are therefore not required. The tool can be loaded by means of thetool changer <strong>and</strong> set <strong>and</strong> programmed in the same way as a conventional cutting tool. The use of themachine under normal operating conditions in daily practice has shown that the special needle usually hasa service life between 2 <strong>and</strong> 5 years without the need for regrinding.Application ranges: Marking on smooth surfaces up to 60 HRC, uneven cast surfaces with differences inthe unevenness of up to 5 mm, arched surfaces (up to 5 mm)h Other information see No. 16531 page 226.Continued next pageLaser marking for industrial identificationLaser marking allows to mark a wide variety of materials without mechanical action, quickly, accurately <strong>and</strong> legibly. It uses highly focussed, invisible, infraredlaser light which introduces so much energy into the workpiece that physical <strong>and</strong> chemical interactions occur at the surface.Examples of engraving:Another advantage of laser marking is the fact that this process works without consumables. This avoids cost-intensive downtimes <strong>and</strong> resulting loss of production.Lasers are used in high-output production processes wherever high availability is a must.High focussing capacity <strong>and</strong> first pulse suppression allow to apply markings with a resolution up to 1000 dpi – Ideal prerequisites for marking two-dimensionalcodes on sensitive materials. Laser marking is quick <strong>and</strong> accurate even at high ambient temperatures. Whether small fonts, graphic symbols or logos – everythingis marked at the exact position <strong>and</strong> true to the original.h We will be happy to give you an on-site demonstration of the laser marking process. Quotation on request.Electric Tools2010/111349