Electro-tools and machines Chapter overview ... - EN / Hahn+Kolb

Electro-tools and machines Chapter overview ... - EN / Hahn+Kolb

Electro-tools and machines Chapter overview ... - EN / Hahn+Kolb

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

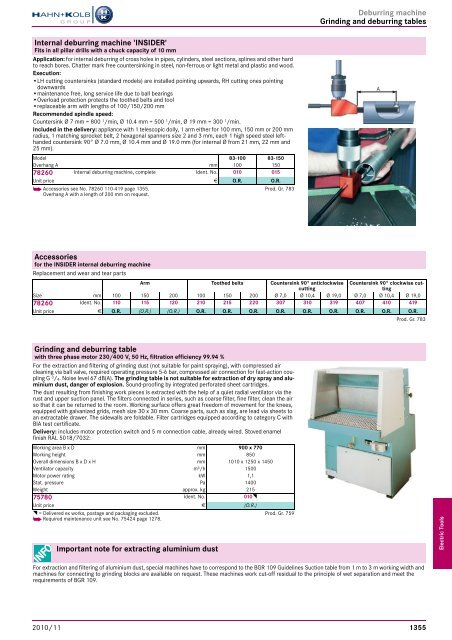

Deburring machineGrinding <strong>and</strong> deburring tablesContinued next pageInternal deburring machine 'INSIDER'Fits in all pillar drills with a chuck capacity of 10 mmApplication: for internal deburring of cross holes in pipes, cylinders, steel sections, splines <strong>and</strong> other hardto reach bores. Chatter mark free countersinking in steel, non-ferrous or light metal <strong>and</strong> plastic <strong>and</strong> wood.Execution:•LH cutting countersinks (st<strong>and</strong>ard models) are installed pointing upwards, RH cutting ones pointingdownwards•maintenance free, long service life due to ball bearings•Overload protection protects the toothed belts <strong>and</strong> tool•replaceable arm with lengths of 100/150/200 mmRecommended spindle speed:Countersink Ø 7 mm = 800 1 /min, Ø 10.4 mm = 500 1 /min, Ø 19 mm = 300 1 /min.Included in the delivery: appliance with 1 telescopic dolly, 1 arm either for 100 mm, 150 mm or 200 mmradius, 1 matching sprocket belt, 2 hexagonal spanners size 2 <strong>and</strong> 3 mm, each 1 high speed steel lefth<strong>and</strong>edcountersink 90° Ø 7.0 mm, Ø 10.4 mm <strong>and</strong> Ø 19.0 mm (for internal Ø from 21 mm, 22 mm <strong>and</strong>25 mm).Model 83-100 83-150Overhang A mm 100 15078260 Internal deburring machine, complete Ident. No. 010 015Unit price E O.R. O.R.h Accessories see No. 78260 110-419 page 1355.Prod. Gr. 783Overhang A with a length of 200 mm on request.AContinued next pageAccessoriesfor the INSIDER internal deburring machineReplacement <strong>and</strong> wear <strong>and</strong> tear partsArm Toothed belts Countersink 90° anticlockwisecuttingCountersink 90° clockwise cuttingSize mm 100 150 200 100 150 200 Ø 7,0 Ø 10,4 Ø 19,0 Ø 7,0 Ø 10,4 Ø 19,078260 Ident. No. 110 115 120 210 215 220 307 310 319 407 410 419Unit price E O.R. (O.R.) (O.R.) O.R. O.R. O.R. O.R. O.R. O.R. O.R. O.R. O.R.Prod. Gr. 783Continued next pageGrinding <strong>and</strong> deburring tablewith three phase motor 230/400 V, 50 Hz, filtration efficiency 99.94 %For the extraction <strong>and</strong> filtering of grinding dust (not suitable for paint spraying), with compressed aircleaning via ball valve, required operating pressure 5-6 bar, compressed air connection for fast-action couplingG 3 /4. Noise level 67 dB(A). The grinding table is not suitable for extraction of dry spray <strong>and</strong> aluminiumdust, danger of explosion. Sound-proofing by integrated perforated sheet cartridges.The dust resulting from finishing work pieces is extracted with the help of a quiet radial ventilator via therust <strong>and</strong> upper suction panel. The filters connected in series, such as coarse filter, fine filter, clean the airso that it can be returned to the room. Working surface offers great freedom of movement for the knees,equipped with galvanized grids, mesh size 30 x 30 mm. Coarse parts, such as slag, are lead via sheets toan extractable drawer. The sidewalls are foldable. Filter cartridges equipped according to category C withBIA test certificate.Delivery: includes motor protection switch <strong>and</strong> 5 m connection cable, already wired. Stoved enamelfinish RAL 5018/7032:Working area B x D mm 900 x 770Working height mm 850Overall dimensions B x D x H mm 1010 x 1250 x 1450Ventilator capacity m³/h 1500Motor power rating kW 1,1Stat. pressure Pa 1400Weight approx. kg 21575780 Ident. No. 010dUnit price E (O.R.)d = Delivered ex works, postage <strong>and</strong> packaging excluded.h Required maintenance unit see No. 75424 page 1278.Prod. Gr. 759Continued next pageImportant note for extracting aluminium dustElectric ToolsFor extraction <strong>and</strong> filtering of aluminium dust, special <strong>machines</strong> have to correspond to the BGR 109 Guidelines Suction table from 1 m to 3 m working width <strong>and</strong><strong>machines</strong> for connecting to grinding blocks are available on request. These <strong>machines</strong> work cut-off residual to the principle of wet separation <strong>and</strong> meet therequirements of BGR 109.2010/111355