standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

standards / manuals / guidelines for small hydro development - AHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

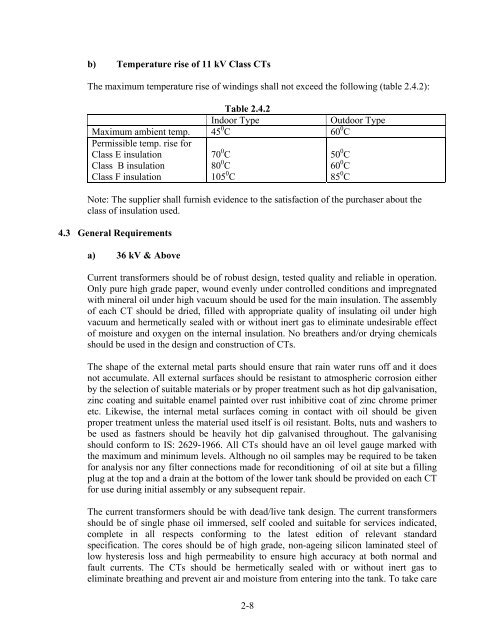

) Temperature rise of 11 kV Class CTsThe maximum temperature rise of windings shall not exceed the following (table 2.4.2):Table 2.4.2Indoor TypeOutdoor TypeMaximum ambient temp. 45 0 C 60 0 CPermissible temp. rise <strong>for</strong>Class E insulationClass B insulationClass F insulation70 0 C80 0 C105 0 C50 0 C60 0 C85 0 CNote: The supplier shall furnish evidence to the satisfaction of the purchaser about theclass of insulation used.4.3 General Requirementsa) 36 kV & AboveCurrent trans<strong>for</strong>mers should be of robust design, tested quality and reliable in operation.Only pure high grade paper, wound evenly under controlled conditions and impregnatedwith mineral oil under high vacuum should be used <strong>for</strong> the main insulation. The assemblyof each CT should be dried, filled with appropriate quality of insulating oil under highvacuum and hermetically sealed with or without inert gas to eliminate undesirable effectof moisture and oxygen on the internal insulation. No breathers and/or drying chemicalsshould be used in the design and construction of CTs.The shape of the external metal parts should ensure that rain water runs off and it doesnot accumulate. All external surfaces should be resistant to atmospheric corrosion eitherby the selection of suitable materials or by proper treatment such as hot dip galvanisation,zinc coating and suitable enamel painted over rust inhibitive coat of zinc chrome primeretc. Likewise, the internal metal surfaces coming in contact with oil should be givenproper treatment unless the material used itself is oil resistant. Bolts, nuts and washers tobe used as fastners should be heavily hot dip galvanised throughout. The galvanisingshould con<strong>for</strong>m to IS: 2629-1966. All CTs should have an oil level gauge marked withthe maximum and minimum levels. Although no oil samples may be required to be taken<strong>for</strong> analysis nor any filter connections made <strong>for</strong> reconditioning of oil at site but a fillingplug at the top and a drain at the bottom of the lower tank should be provided on each CT<strong>for</strong> use during initial assembly or any subsequent repair.The current trans<strong>for</strong>mers should be with dead/live tank design. The current trans<strong>for</strong>mersshould be of single phase oil immersed, self cooled and suitable <strong>for</strong> services indicated,complete in all respects con<strong>for</strong>ming to the latest edition of relevant <strong>standards</strong>pecification. The cores should be of high grade, non-ageing silicon laminated steel oflow hysteresis loss and high permeability to ensure high accuracy at both normal andfault currents. The CTs should be hermetically sealed with or without inert gas toeliminate breathing and prevent air and moisture from entering into the tank. To take care2-8