MicroMaster 6SE92 - ECT Sales & Service

MicroMaster 6SE92 - ECT Sales & Service

MicroMaster 6SE92 - ECT Sales & Service

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

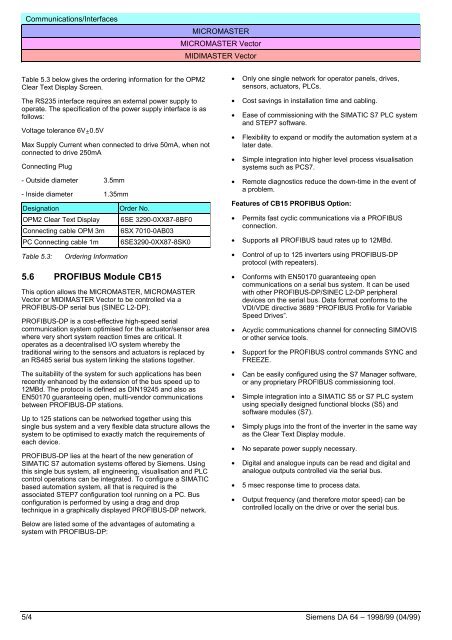

Communications/InterfacesMICROMASTERMICROMASTER VectorMIDIMASTER VectorTable 5.3 below gives the ordering information for the OPM2Clear Text Display Screen.The RS235 interface requires an external power supply tooperate. The specification of the power supply interface is asfollows:Voltage tolerance 6V±0.5VMax Supply Current when connected to drive 50mA, when notconnected to drive 250mAConnecting Plug- Outside diameter 3.5mm- Inside diameter 1.35mmDesignationOPM2 Clear Text DisplayConnecting cable OPM 3mPC Connecting cable 1mTable 5.3:Ordering InformationOrder No.6SE 3290-0XX87-8BF06SX 7010-0AB036SE3290-0XX87-8SK05.6 PROFIBUS Module CB15This option allows the MICROMASTER, MICROMASTERVector or MIDIMASTER Vector to be controlled via aPROFIBUS-DP serial bus (SINEC L2-DP).PROFIBUS-DP is a cost-effective high-speed serialcommunication system optimised for the actuator/sensor areawhere very short system reaction times are critical. Itoperates as a decentralised I/O system whereby thetraditional wiring to the sensors and actuators is replaced byan RS485 serial bus system linking the stations together.The suitability of the system for such applications has beenrecently enhanced by the extension of the bus speed up to12MBd. The protocol is defined as DIN19245 and also asEN50170 guaranteeing open, multi-vendor communicationsbetween PROFIBUS-DP stations.Up to 125 stations can be networked together using thissingle bus system and a very flexible data structure allows thesystem to be optimised to exactly match the requirements ofeach device.PROFIBUS-DP lies at the heart of the new generation ofSIMATIC S7 automation systems offered by Siemens. Usingthis single bus system, all engineering, visualisation and PLCcontrol operations can be integrated. To configure a SIMATICbased automation system, all that is required is theassociated STEP7 configuration tool running on a PC. Busconfiguration is performed by using a drag and droptechnique in a graphically displayed PROFIBUS-DP network.• Only one single network for operator panels, drives,sensors, actuators, PLCs.• Cost savings in installation time and cabling.• Ease of commissioning with the SIMATIC S7 PLC systemand STEP7 software.• Flexibility to expand or modify the automation system at alater date.• Simple integration into higher level process visualisationsystems such as PCS7.• Remote diagnostics reduce the down-time in the event ofa problem.Features of CB15 PROFIBUS Option:• Permits fast cyclic communications via a PROFIBUSconnection.• Supports all PROFIBUS baud rates up to 12MBd.• Control of up to 125 inverters using PROFIBUS-DPprotocol (with repeaters).• Conforms with EN50170 guaranteeing opencommunications on a serial bus system. It can be usedwith other PROFIBUS-DP/SINEC L2-DP peripheraldevices on the serial bus. Data format conforms to theVDI/VDE directive 3689 “PROFIBUS Profile for VariableSpeed Drives”.• Acyclic communications channel for connecting SIMOVISor other service tools.• Support for the PROFIBUS control commands SYNC andFREEZE.• Can be easily configured using the S7 Manager software,or any proprietary PROFIBUS commissioning tool.• Simple integration into a SIMATIC S5 or S7 PLC systemusing specially designed functional blocks (S5) andsoftware modules (S7).• Simply plugs into the front of the inverter in the same wayas the Clear Text Display module.• No separate power supply necessary.• Digital and analogue inputs can be read and digital andanalogue outputs controlled via the serial bus.• 5 msec response time to process data.• Output frequency (and therefore motor speed) can becontrolled locally on the drive or over the serial bus.Below are listed some of the advantages of automating asystem with PROFIBUS-DP:5/4 Siemens DA 64 – 1998/99 (04/99)