ECOBuilder-Specifiers Journal spring2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

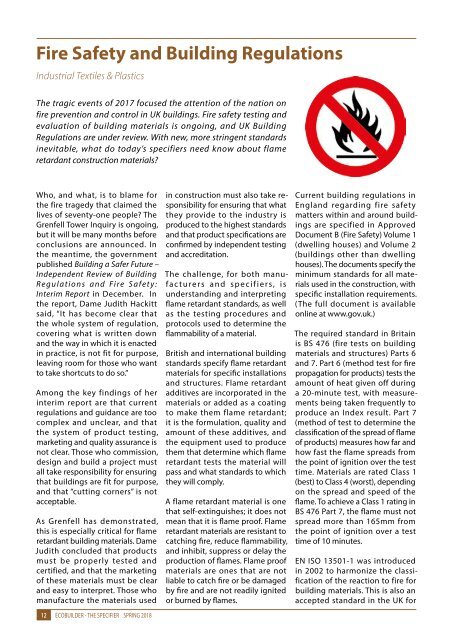

Fire Safety and Building Regulations<br />

Industrial Textiles & Plastics<br />

The tragic events of 2017 focused the attention of the nation on<br />

fire prevention and control in UK buildings. Fire safety testing and<br />

evaluation of building materials is ongoing, and UK Building<br />

Regulations are under review. With new, more stringent standards<br />

inevitable, what do today’s specifiers need know about flame<br />

retardant construction materials?<br />

Who, and what, is to blame for<br />

the fire tragedy that claimed the<br />

lives of seventy-one people? The<br />

Grenfell Tower Inquiry is ongoing,<br />

but it will be many months before<br />

conclusions are announced. In<br />

the meantime, the government<br />

published Building a Safer Future –<br />

Independent Review of Building<br />

Regulations and Fire Safety:<br />

Interim Report in December. In<br />

the report, Dame Judith Hackitt<br />

said, “It has become clear that<br />

the whole system of regulation,<br />

covering what is written down<br />

and the way in which it is enacted<br />

in practice, is not fit for purpose,<br />

leaving room for those who want<br />

to take shortcuts to do so.”<br />

Among the key findings of her<br />

interim report are that current<br />

regulations and guidance are too<br />

complex and unclear, and that<br />

the system of product testing,<br />

marketing and quality assurance is<br />

not clear. Those who commission,<br />

design and build a project must<br />

all take responsibility for ensuring<br />

that buildings are fit for purpose,<br />

and that “cutting corners” is not<br />

acceptable.<br />

As Grenfell has demonstrated,<br />

this is especially critical for flame<br />

retardant building materials. Dame<br />

Judith concluded that products<br />

must be properly tested and<br />

certified, and that the marketing<br />

of these materials must be clear<br />

and easy to interpret. Those who<br />

manufacture the materials used<br />

10 12 ECOBUILDER - THE SPECIFIER 2018 SPRING 2018<br />

in construction must also take responsibility<br />

for ensuring that what<br />

they provide to the industry is<br />

produced to the highest standards<br />

and that product specifications are<br />

confirmed by independent testing<br />

and accreditation.<br />

The challenge, for both manufacturers<br />

and specifiers, is<br />

understanding and interpreting<br />

flame retardant standards, as well<br />

as the testing procedures and<br />

protocols used to determine the<br />

flammability of a material.<br />

British and international building<br />

standards specify flame retardant<br />

materials for specific installations<br />

and structures. Flame retardant<br />

additives are incorporated in the<br />

materials or added as a coating<br />

to make them flame retardant;<br />

it is the formulation, quality and<br />

amount of these additives, and<br />

the equipment used to produce<br />

them that determine which flame<br />

retardant tests the material will<br />

pass and what standards to which<br />

they will comply.<br />

A flame retardant material is one<br />

that self-extinguishes; it does not<br />

mean that it is flame proof. Flame<br />

retardant materials are resistant to<br />

catching fire, reduce flammability,<br />

and inhibit, suppress or delay the<br />

production of flames. Flame proof<br />

materials are ones that are not<br />

liable to catch fire or be damaged<br />

by fire and are not readily ignited<br />

or burned by flames.<br />

Current building regulations in<br />

England regarding fire safety<br />

matters within and around buildings<br />

are specified in Approved<br />

Document B (Fire Safety) Volume 1<br />

(dwelling houses) and Volume 2<br />

(buildings other than dwelling<br />

houses). The documents specify the<br />

minimum standards for all materials<br />

used in the construction, with<br />

specific installation requirements.<br />

(The full document is available<br />

online at www.gov.uk.)<br />

The required standard in Britain<br />

is BS 476 (fire tests on building<br />

materials and structures) Parts 6<br />

and 7. Part 6 (method test for fire<br />

propagation for products) tests the<br />

amount of heat given off during<br />

a 20-minute test, with measurements<br />

being taken frequently to<br />

produce an Index result. Part 7<br />

(method of test to determine the<br />

classification of the spread of flame<br />

of products) measures how far and<br />

how fast the flame spreads from<br />

the point of ignition over the test<br />

time. Materials are rated Class 1<br />

(best) to Class 4 (worst), depending<br />

on the spread and speed of the<br />

flame. To achieve a Class 1 rating in<br />

BS 476 Part 7, the flame must not<br />

spread more than 165mm from<br />

the point of ignition over a test<br />

time of 10 minutes.<br />

EN ISO 13501-1 was introduced<br />

in 2002 to harmonize the classification<br />

of the reaction to fire for<br />

building materials. This is also an<br />

accepted standard in the UK for