ECOBuilder-Specifiers Journal spring2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For use on: Conference Hall<br />

Fire & Surface Contamination Protection for Wood & Painted Walls<br />

Safety & Environmental<br />

Protection made Reality<br />

Fire Safety Order 2005<br />

Since 2005 it has been mandatory to meet<br />

current fire and other safety standards<br />

in existing buildings as well as new<br />

construction.<br />

Priority areas for protection were corridors,<br />

stairs, landings and common areas.<br />

The Risks<br />

Flammable Surfaces<br />

Wood is universally recognised as a<br />

contributor to flamespread, smoke and<br />

fire intensity.<br />

UKAS Fire Tests have demonstrated that<br />

non-combustible surfaces can create<br />

flamespread, smoke & flaming droplet<br />

risks if coated with multiple layers of<br />

various paints.<br />

Other Risk Surfaces<br />

Board and Artex containing Asbestos<br />

fibres were regrettably common in the<br />

20 th Century. Flame Retardant paint<br />

based upon Antimony - a heavy metal<br />

which emitted a toxic gas to suppress<br />

flamespread - was widely applied before<br />

Antimony was omitted a few years ago.<br />

Painted woodchip and textured wallpaper<br />

have both been widely used, while<br />

anti-graffiti paints resistant to future<br />

paints adhering are applied to surfaces<br />

impossible to abrade.<br />

Fire Standards<br />

Required Fire Standards<br />

Current minimum compliant standards for<br />

corridors, stairways, landings & common<br />

areas are BS 476 Class O and the new BS<br />

EN Class B.<br />

Old & New British Standard Explained<br />

Old BS 476 Class O combines control of<br />

flamespread with fire intensity.<br />

BS EN Class B combines control of<br />

flamespread & fire intensity. The BS EN<br />

standard add protection from smoke - safe<br />

standards s1 & s2, plus flaming droplets -<br />

safe standard dO.<br />

Impediments to Safety with Fire<br />

Protection Products<br />

Compatibility of Finish to Fire<br />

Treatment<br />

All too often fire protection is compromised<br />

by overlaying with unprotected wood<br />

veneers or untested paints, varnish,<br />

woodstain or - even worse - oils.<br />

EITHER - finished surface veneers or<br />

coatings should have passed fire tests to<br />

Class O or B - ideally to s1 or s2, dO in<br />

conjunction with any pre-treatment - OR -<br />

a fire protective coating be applied from a<br />

manufacturer prepared to Certify the final<br />

specification to these standards.<br />

Complicated, Confusing or Demanding<br />

Fire Protection Products<br />

Many systems depend upon specifiers or<br />

contractors to know a surface’s coating<br />

history or otherwise assess surfaces’<br />

flamespread risk.<br />

Other systems commonly depend on<br />

application of 4+ coats. Seldom are all<br />

coats applied.<br />

30, 60, 90, 120 mins Fire Resistance<br />

Increasing Fire Resistance on wood, wood-based boards, plasterboard, cement board or concrete is notably less straightforward<br />

than flamespread protection. Each affected project’s relevant surfaces and construction need to be assessed individually.<br />

In consequence, in addition to information sheets, Thermoguard stress the need for expert advice from Thermoguard’s Technical<br />

dept., available free of charge to property owners and managers, Architects, Surveyors and Contractors.<br />

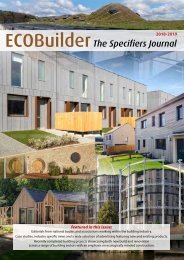

Designers have wanted to combine different visual effects with<br />

fire protection. To meet this need, Thermoguard developed<br />

a range of colour strengths, ranging from a “mist” through<br />

various degrees of translucence, through to opaque, based<br />

upon any BS, RAL or Woodstain colour.<br />

The photo shows an award-winning chapel project protected to<br />

Class B s2 dO by Thermoguard clear fire protection with Mist<br />

white overcoat seal.<br />

Protection made simple by Thermoguard<br />

To enable fire protection to be achieved in the real-world,<br />

22 years ago Thermoguard concluded the following were needed.<br />

UKAS - tested finishes to apply over any basecoat or penetrating<br />

fluid requiring a finish.<br />

Products to provide Class O - and when BS EN arrived Class<br />

B s1/s2 dO on wood, wood-based or building boards, whether<br />

bare, wallpapered, coated with decorative paints & varnishes or<br />

contaminated with asbestos.<br />

Simple and economical 2 coat systems<br />

comprising 1 coat basecoat & 1 coat finish<br />

readily distinguished from one another to<br />

avoid coat omission.<br />

Certificate of Supply<br />

No.<br />

Thermoguard Fire Protection Coatings<br />

Kirkby Street, Hull, HU2 0HE<br />

This is to certify that: Responsible Decorators<br />

Of Unit 20 , Industrial Estate ,<br />

Anytown, AT6 4ZZ<br />

Has purchased sufficient: Thermoguard Timbercoat & SFR<br />

To treat: 200 sq m Internal Softwood Partitions<br />

To achieve compliance with: Class B s1 dO<br />

The owners of historic Feering Bury<br />

barn required Class O protection for<br />

Grand Designs. The owners wanted<br />

and English Heritage required the<br />

wood to retain it’s natural look, so<br />

Thermoguard Fire Varnish Matt was<br />

used in an award-winning project.<br />

Packaging in 20 or 25 sq m and 80 or 100 sq<br />

m cans to avoid errors ordering or applying.<br />

A robust Fire Certification process for<br />

individual projects to give confidence to<br />

clients, specifiers and Authorities.<br />

Entirely water-based, ultra-low or zero VoC<br />

environmentally - friendly products.<br />

Point House<br />

York<br />

Date: 13 Feb 2018 Signed:<br />

Contractor’s Statement<br />

I / We certify that I / We have applied the products listed above in accordance<br />

with the manufacturer’s written specification and technical data sheet.<br />

Date: Signed:<br />

For and on behalf of:<br />

Maintenance<br />

1. Maintenance should only be carried out using an overcoat approved by<br />

Thermoguard UK Ltd in accordance with Thermoguard UK instructions.<br />

2. Small areas of damage are self-sealing in the event of a fire but should be<br />

repaired as soon as possible.<br />

Thermoguard Fire Protection Paints, Varnish & Penetrating Fluid are available from Decorators’ Merchants<br />

throughout the British Isles.<br />

www.thermoguard.co.uk technical@thermoguard.co.uk 01142 768008<br />

46 ECOBUILDER - THE SPECIFIER SPRING 2018