SPW Product Catalogue 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

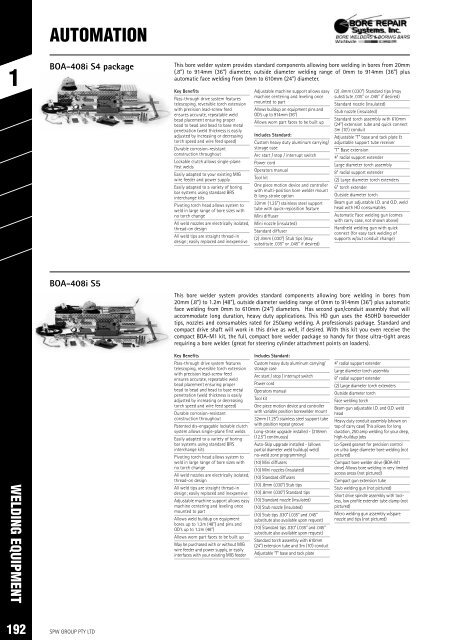

AUTOMATION<br />

BOA-408i S4 package<br />

This bore welder system provides standard components allowing bore welding in bores from 20mm<br />

(.8”) to 914mm (36”) diameter, outside diameter welding range of 0mm to 914mm (36”) plus<br />

automatic face welding from 0mm to 610mm (24”) diameter.<br />

Key Benefits<br />

Pass-through drive system features<br />

telescoping, reversible torch extension<br />

with precision lead-screw feed<br />

ensures accurate, repeatable weld<br />

bead placement ensuring proper<br />

bead to bead and bead to base metal<br />

penetration (weld thickness is easily<br />

adjusted by increasing or decreasing<br />

torch speed and wire feed speed)<br />

Durable corrosion-resistant<br />

construction throughout<br />

Lockable clutch allows single-plane<br />

first welds<br />

Easily adapted to your existing MIG<br />

wire feeder and power supply<br />

Easily adapted to a variety of boring<br />

bar systems using standard BRS<br />

interchange kits<br />

Pivoting torch head allows system to<br />

weld in large range of bore sizes with<br />

no torch change<br />

All weld nozzles are electrically isolated,<br />

thread-on design<br />

All weld tips are straight thread-in<br />

design; easily replaced and inexpensive<br />

Adjustable machine support allows easy<br />

machine centering and leveling once<br />

mounted to part<br />

Allows buildup on equipment pins and<br />

OD’s up to 914mm (36”)<br />

Allows worn part faces to be built up<br />

(2) .8mm (.030”) Standard tips (may<br />

substitute .035” or .045” if desired)<br />

Standard nozzle (insulated)<br />

Stub nozzle (insulated)<br />

Standard torch assembly with 610mm<br />

(24”) extension tube and quick connect<br />

3m (10’) conduit<br />

Includes Standard:<br />

Adjustable “T” base and tack plate &<br />

Custom heavy duty aluminum carrying/ adjustable support tube receiver<br />

storage case<br />

”T” Base extension<br />

Arc start / stop / interrupt switch<br />

4” radial support extender<br />

Power cord<br />

Large diameter torch assembly<br />

Operators manual<br />

8” radial support extender<br />

Tool kit<br />

(2) Large diameter torch extenders<br />

One piece motion device and controller<br />

6” torch extender<br />

with multi-position bore welder mount<br />

& long-stroke option<br />

Outside diameter torch<br />

32mm (1.25”) stainless steel support Beam gun adjustable I.D. and O.D. weld<br />

tube with quick-reposition feature head with HD consumables<br />

Mini diffuser<br />

Automatic Face welding gun (comes<br />

with carry case, not shown above)<br />

Mini nozzle (insulated)<br />

Handheld welding gun with quick<br />

Standard diffuser<br />

connect (for easy tack welding of<br />

(2) .8mm (.030”) Stub tips (may supports w/out conduit change)<br />

substitute .035” or .045” if desired)<br />

BOA-408i S5<br />

This bore welder system provides standard components allowing bore welding in bores from<br />

20mm (.8”) to 1.2m (48”), outside diameter welding range of 0mm to 914mm (36”) plus automatic<br />

face welding from 0mm to 610mm (24”) diameters. Has second gun/conduit assembly that will<br />

accommodate long duration, heavy duty applications. This HD gun uses the 450HD borewelder<br />

tips, nozzles and consumables rated for 250amp welding. A professionals package. Standard and<br />

compact drive shaft will work in this drive as well, if desired. With this kit you even receive the<br />

compact BOA-M1 kit, the full, compact bore welder package so handy for those ultra-tight areas<br />

requiring a bore welder. (great for steering cylinder attachment points on loaders).<br />

WELDING EQUIPMENT<br />

Key Benefits<br />

Pass-through drive system features<br />

telescoping, reversible torch extension<br />

with precision lead-screw feed<br />

ensures accurate, repeatable weld<br />

bead placement ensuring proper<br />

bead to bead and bead to base metal<br />

penetration (weld thickness is easily<br />

adjusted by increasing or decreasing<br />

torch speed and wire feed speed)<br />

Durable corrosion-resistant<br />

construction throughout<br />

Patented dis-engagable lockable clutch<br />

system allows single-plane first welds<br />

Easily adapted to a variety of boring<br />

bar systems using standard BRS<br />

interchange kits<br />

Pivoting torch head allows system to<br />

weld in large range of bore sizes with<br />

no torch change<br />

All weld nozzles are electrically isolated,<br />

thread-on design<br />

All weld tips are straight thread-in<br />

design; easily replaced and inexpensive<br />

Adjustable machine support allows easy<br />

machine centering and leveling once<br />

mounted to part<br />

Allows weld buildup on equipment<br />

bores up to 1.2m (48”) and pins and<br />

OD’s up to 1.2m (48”)<br />

Allows worn part faces to be built up<br />

May be purchased with or without MIG<br />

wire feeder and power supply, or easily<br />

interfaces with your existing MIG feeder<br />

Includes Standard:<br />

Custom heavy duty aluminum carrying/<br />

storage case<br />

Arc start / stop / interrupt switch<br />

Power cord<br />

Operators manual<br />

Tool kit<br />

One piece motion device and controller<br />

with variable position borewelder mount<br />

32mm (1.25”) stainless steel support tube<br />

with position repeat groove<br />

Long-stroke upgrade installed - (318mm<br />

(12.5”) continuous)<br />

Auto-Skip upgrade installed - (allows<br />

partial diameter weld buildup/ weld/<br />

no-weld zone programming)<br />

(10) Mini diffusers<br />

(10) Mini nozzles (insulated)<br />

(10) Standard diffusers<br />

(10) .8mm (.030”) Stub tips<br />

(10) .8mm (.030”) Standard tips<br />

(10) Standard nozzle (insulated)<br />

(10) Stub nozzle (insulated)<br />

(10) Stub tips .030” (.035” and .045”<br />

substitute also available upon request)<br />

(10) Standard tips .030” (.035” and .045”<br />

substitute also available upon request)<br />

Standard torch assembly with 610mm<br />

(24”) extension tube and 3m (10’) conduit<br />

Adjustable “T” base and tack plate<br />

4” radial support extender<br />

Large diameter torch assembly<br />

8” radial support extender<br />

(2) Large diameter torch extenders<br />

Outside diameter torch<br />

Face welding torch<br />

Beam gun adjustable I.D. and O.D. weld<br />

head<br />

Heavy duty conduit assembly (shown on<br />

top of carry case) This allows for long<br />

duration, 250 amp welding for your deep,<br />

high-buildup jobs<br />

Lo-Speed gearset for precision control<br />

on ultra large diameter bore welding (not<br />

pictured)<br />

Compact bore welder drive (BOA-M1<br />

drive) Allows bore welding in very limited<br />

access areas (not pictured)<br />

Compact gun extension tube<br />

Stub welding gun (not pictured)<br />

Short drive spindle assembly with toolless,<br />

low profile extender tube clamp (not<br />

pictured)<br />

Micro welding gun assembly w/spare<br />

nozzle and tips (not pictured)<br />

192 <strong>SPW</strong> GROUP PTY LTD