SPW Product Catalogue 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WIRES MIG<br />

5<br />

CONSUMABLES<br />

374<br />

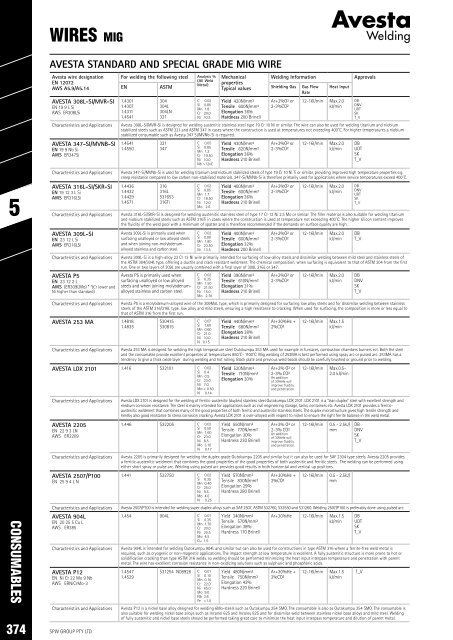

AVESTA STANDARD AND SPECIAL GRADE MIG WIRE<br />

Avesta wire designation<br />

EN 12072<br />

AWS A5.9/A5.14<br />

AVESTA 308L-SI/MVR-SI<br />

EN 19 9 L Si<br />

AWS ER308LSi<br />

Characteristics and Applications<br />

AVESTA 347-SI/MVNB-SI<br />

EN 19 9 Nb Si<br />

AWS ER347Si<br />

Characteristics and Applications<br />

AVESTA 316L-SI/SKR-SI<br />

EN 19 12 3 L Si<br />

AWS ER316LSi<br />

Characteristics and Applications<br />

AVESTA 309L-SI<br />

EN 23 12 L Si<br />

AWS ER316LSi<br />

Characteristics and Applications<br />

AVESTA P5<br />

EN 23 12 2 L<br />

AWS (ER309LMo) * *(Cr lower and<br />

Ni higher than standard)<br />

Characteristics and Applications<br />

<strong>SPW</strong> GROUP PTY LTD<br />

For welding the following steel Analysis % Mechanical Welding Information<br />

(All Weld<br />

Metal) properties<br />

EN ASTM Typical values Shielding Gas Gas Flow<br />

Rate<br />

1.4301<br />

1.4307<br />

1.4311<br />

1.4541<br />

304<br />

304L<br />

304LN<br />

321<br />

C 0.02<br />

Si 0.85<br />

Mn 1.8<br />

Cr 20.0<br />

Ni 10.5<br />

Yield 420N/mm²<br />

Tensile 600N/mm²<br />

Elongation 36%<br />

Hardness 200 Brinell<br />

Ar+2%O² or<br />

2-3%CO²<br />

12-16I/min<br />

Heat Input<br />

Max.2.0<br />

kJ/min<br />

Approvals<br />

Avesta 308L-Si/MVR-Si is designed for welding austenitic stainless steel type 19 Cr 10 Ni or similar. The wire can also be used for welding titanium and niobium<br />

stabilized steels such as ASTM 321 and ASTM 347 in cases where the construction is used at temperatures not exceeding 400˚C. For higher temperatures a niobium<br />

stabilized consumable such as Avesta 347 Si/MVNb-Si is required.<br />

1.4541<br />

1.4550<br />

321<br />

347<br />

C 0.05<br />

Si 0.85<br />

Mn 1.2<br />

Cr 19.50<br />

Ni 10.0<br />

Nb >12xC<br />

Yield 430N/mm²<br />

Tensile 620N/mm²<br />

Elongation 36%<br />

Hardness 210 Brinell<br />

Ar+2%O² or<br />

2-3%CO²<br />

12-16I/min<br />

Max.2.0<br />

kJ/min<br />

Avesta 347-Si/MVNb-Si is used for welding titanium and niobium stabilized steels of type 19 Cr 10 Ni Ti or similar, providing improved high temperature properties e.g.<br />

creep resistance compared to low carbon non-stabilized materials. 347-Si/MVNb-Si is therefore primarily used for applications where service temperatures exceed 400˚C.<br />

1.4436<br />

1.4432<br />

1.4429<br />

1.4571<br />

AVESTA 253 MA 1.4818<br />

1.4835<br />

Characteristics and Applications<br />

316<br />

316L<br />

S31653<br />

316Ti<br />

C 0.02<br />

Si 0.85<br />

Mn 1.7<br />

Cr 18.50<br />

Ni 12.0<br />

Mo 2.6<br />

Yield 400N/mm²<br />

Tensile 600N/mm²<br />

Elongation 36%<br />

Hardness 210 Brinell<br />

Ar+2%O² or<br />

2-3%CO²<br />

12-16I/min<br />

Max.2.0<br />

kJ/min<br />

Avesta 316L-Si/SKR-Si is designed for welding austenitic stainless steel of type 17 Cr 12 Ni 2.5 Mo or similar. The filler material is also suitable for welding titanium<br />

and niobium stabilized steels such as ASTM 316Ti in cases where the construction is used at temperature not exceeding 400˚C. The higher silicon content improves<br />

the fluidity of the weld pool with a minimum of spatter and is therefore recommended if the demands on surface quality are high.<br />

Avesta 309L-Si is primarily used when<br />

surfacing unalloyed or low alloyed steels<br />

and when joining non-molybdenumalloyed<br />

stainless and carbon steel.<br />

C 0.02<br />

Si 0.80<br />

Mn 1.80<br />

Cr 23.50<br />

Ni 13.5<br />

Yield 400N/mm²<br />

Tensile 600N/mm²<br />

Elongation 32%<br />

Hardness 200 Brinell<br />

Ar+2%O² or<br />

2-3%CO²<br />

12-16I/min<br />

Max.2.0<br />

kJ/min<br />

Avesta 309L-Si is a high-alloy 23 Cr 13 Ni wire primarily intended for surfacing of low-alloy steels and dissimilar welding between mild steel and stainless steels of<br />

the ASTM 304/304L type, offering a ductile and crack resistant weldment. The chemical composition, when surfacing is equivalent to that of ASTM 304 from the first<br />

run. One or two layers of 309L are usually combined with a final layer of 308L 316L or 347.<br />

Avesta P5 is primarily used when<br />

surfacing unalloyed or low alloyed<br />

steels and when joining molybdenumalloyed<br />

stainless and carbon steel.<br />

C 0.02<br />

Si 0.35<br />

Mn 1.50<br />

Cr 21.50<br />

Ni 15.0<br />

Mo 2.70<br />

Yield 390N/mm²<br />

Tensile 610N/mm²<br />

Elongation 31%<br />

Hardness 210 Brinell<br />

Ar+2%O² or<br />

2-3%CO²<br />

12-16I/min<br />

Max.2.0<br />

kJ/min<br />

Avesta P5 is a molybdenum-alloyed wire of the 309MoL type, which is primarily designed for surfacing low alloy steels and for dissimilar welding between stainless<br />

steels of the ASTM 316/316L type, low alloy and mild steels, ensuring a high resistance to cracking. When used for surfacing, the composition is more or less equal to<br />

that of ASTM 316 from the first run.<br />

S30415<br />

S30815<br />

C 0.07<br />

Si 1.60<br />

Mn 0.60<br />

Cr 21.0<br />

Ni 10.0<br />

N 0.15<br />

Yield 440N/mm²<br />

Tensile 680N/mm²<br />

Elongation 38%<br />

Hardness 210 Brinell<br />

Ar+30%He +<br />

2%CO²<br />

12-16I/min<br />

Max.1.5<br />

kJ/min<br />

Avesta 253 MA is designed for welding the high temperature steel Outokumpu 253 MA used for example in furnaces, combustion chambers burners ect. Both the steel<br />

and the consumable provide excellent properties at temperatures 850˚C- 1100˚C. Mig welding of 253MA is best performed using spray arc or pulsed arc. 253MA has a<br />

tendency to give a thick oxide layer during welding and hot rolling. Black plate and previous weld beads should be carefully brushed or ground prior to welding.<br />

AVESTA LDX 2101 1.416 S32101 C 0.02<br />

Si 0.4<br />

Mn 0.5<br />

Cr 23.0<br />

Ni 7.0<br />

Mo < 0.50<br />

N 0.14<br />

Characteristics and Applications<br />

AVESTA 2205<br />

EN 22 9 3 LN<br />

AWS ER2209<br />

Characteristics and Applications<br />

AVESTA 2507/P100<br />

EN 25 9 4 L N<br />

Characteristics and Applications<br />

AVESTA 904L<br />

EN 20 25 5 Cu L<br />

AWS ER385<br />

Characteristics and Applications<br />

AVESTA P12<br />

EN Ni Cr 22 Mo 9 Nb<br />

AWS ERNiCrMo-3<br />

Characteristics and Applications<br />

Yield 520N/mm²<br />

Tensile 710N/mm²<br />

Elongation 30%<br />

Ar+2% O² or<br />

2-3% CO²<br />

An addition<br />

of 30%He will<br />

improve fluidity<br />

and penetration.<br />

12-16I/min<br />

Max.0.5-<br />

2.0 kJ/min<br />

Avesta LDX 2101 is designed for the welding of ferritic-austenitic (duplex) stainless steel Outokumpu LDX 2101. LDX 2101 is a “lean duplex” steel with excellent strength and<br />

medium corrosion resistance. The steel is mainly intended for applications such as civil engineering storage, tanks, containers etc. Avesta LDX 2101 provides a ferriticaustenitic<br />

weldment that combines many of the good properties of both ferritic and austenitic stainless steels. The duplex microstructure gives high tensile strength and<br />

hereby also good resistance to stress corrosion cracking. Avesta LDX 2101 is over-alloyed with respect to nickel to ensure the right ferrite balance in the weld metal.<br />

1.446 S32205 C 0.02<br />

Si 0.50<br />

Mn 1.60<br />

Cr 23.0<br />

Ni 8.5<br />

Mo 3.10<br />

N 0.17<br />

Yield 550N/mm²<br />

Tensile 770N/mm²<br />

Elongation 30%<br />

Hardness 230 Brinell<br />

Ar+2% O² or<br />

2-3% CO²<br />

An addition<br />

of 30%He will<br />

improve fluidity<br />

and penetration.<br />

12-16I/min<br />

0.5 - 2.5kJ/<br />

mm<br />

Avesta 2205 is primarily designed for welding the duplex grade Outokumpu 2205 and similar but it can also be used for SAF 2304 type steels. Avesta 2205 provides<br />

a ferritic-austenitic weldment that combines the good properties of the good properties of both austenitic and ferritic steels . The welding can be performed using<br />

either short spray or pulse arc. Welding using pulsed arc provides good results in both horizontal and vertical up positions.<br />

1.441 S32750 C 0.02<br />

Si 0.35<br />

Mn 0.40<br />

Cr 25.0<br />

Ni 9.5<br />

Mo 4.0<br />

N 0.25<br />

Yield 570N/mm²<br />

Tensile 830N/mm²<br />

Elongation 29%<br />

Hardness 280 Brinell<br />

Ar+30%He +<br />

2%CO²<br />

12-16I/min<br />

0.5 - 2.5kJ/<br />

mm<br />

Avesta 2507/P100 is intended for welding super duplex alloys such as SAF 2507, ASTM S32760, S32550 and S31260. Welding 2507/P100 is preferably done using pulsed arc.<br />

1.454 904L C 0.01<br />

Si 0.35<br />

Mn 1.70<br />

Cr 20.0<br />

Ni 25.5<br />

Mo 4.5<br />

Cu 1.5<br />

Yield 340N/mm²<br />

Tensile 570N/mm²<br />

Elongation 38%<br />

Hardness 170 Brinell<br />

Ar+30%He 12-16I/min Max.1.5<br />

kJ/min<br />

Avesta 904L is intended for welding Outokumpu 904L and similar but can also be used for constructions in type ASTM 316 where a ferrite-free weld metal is<br />

required, such as cryogenic or non-magnetic applications. The impact strength at low temperature is excellent. A fully austenitic structure is more prone to hot or<br />

solidification cracking than type ASTM 316 welds, so welding should be performed minimizing the heat input interpass temperature and penetration with parent<br />

metal. The wire has excellent corrosion resistance in non-oxidizing solutions such as sulphuric and phosphoric acids.<br />

1.4547<br />

1.4529<br />

S31254 N08926 C 0.01<br />

Si 0.10<br />

Mn 0.10<br />

Cr 22.0<br />

Ni 65.0<br />

Mo 9.0<br />

Nb 3.6<br />

Fe