- Page 1 and 2:

AUST: 1300 WELDER (935 337) NZ: 080

- Page 3:

WELDING EQUIPMENT GAS EQUIPMENT IND

- Page 6 and 7:

ACCESSORIES 1 ELECTRODE HOLDERS TWI

- Page 8 and 9:

ACCESSORIES 1 LENCO® GROUND CLAMPS

- Page 10 and 11:

ACCESSORIES 1 WORK CLAMPS SPRING LO

- Page 12 and 13:

1 ACCESSORIES COOL ARC® 20 Item Nu

- Page 14 and 15:

ACCESSORIES 1 WELDING EQUIPMENT PRO

- Page 16 and 17:

1 ACCESSORIES L.I.T. PROCESS A safe

- Page 18 and 19:

ACCESSORIES 1 TIG CHAMP BRUSH DC PL

- Page 20 and 21:

1 ACCESSORIES CERAMIC BACKING BAR C

- Page 22 and 23:

1 ACCESSORIES TIP CLEANERS Part No.

- Page 24 and 25:

1 ACCESSORIES HAND TOOLS 330-B SMAL

- Page 26 and 27:

1 WELDING EQUIPMENT ACCESSORIES ARC

- Page 28 and 29:

1 ACCESSORIES K112 & K113 SUB ARC G

- Page 30 and 31:

ACCESSORIES 1 ARC GOUGING TORCHES P

- Page 32 and 33:

ACCESSORIES 1 K231 SUB ARC ASSEMBLY

- Page 34 and 35:

ACCESSORIES 1 CONTOUR® & CURV O MA

- Page 36 and 37:

1 ACCESSORIES SUMNER ULTRA CLAMPS -

- Page 38 and 39:

ACCESSORIES 1 SINGLE JACKSCREW CHAI

- Page 40 and 41:

1 ACCESSORIES RIM CLAMPS WARNINGS:

- Page 42 and 43:

ACCESSORIES 1 SADDLE MACHINE Depend

- Page 44 and 45:

ACCESSORIES 1 MONARCH BAND PIPE CUT

- Page 46 and 47:

1 ACCESSORIES PIPE WRAP The Mathey

- Page 48 and 49:

ACCESSORIES TRI TOOL INC. 1 PIPE BE

- Page 50 and 51:

ACCESSORIES TRI TOOL INC. 1 1” TO

- Page 52 and 53:

ACCESSORIES TRI TOOL INC. 1 TRI TOO

- Page 54 and 55:

ACCESSORIES 1 ARDROX 907PB ARDROX 9

- Page 56 and 57:

MMAW (STICK) WELDERS EURO No4 415V

- Page 58 and 59:

20 3.6 No MMAW (STICK) WELDERS 20 2

- Page 60 and 61:

415V AUX 5kVA 240V AUX 4kVA CUT 16m

- Page 62 and 63:

1 STICK WELDERS INVERTEC® K12040-2

- Page 64 and 65:

1 STICK WELDERS Minarc Evo 150 & 14

- Page 66 and 67:

20 3.6 TIG WELDERS 20 3.6 20 3.6 20

- Page 68 and 69:

TIG WELDERS 20 3.6 20 3.6 20 3.6 1

- Page 70 and 71:

1 TIG WELDERS INVERTEC® V160-TP K1

- Page 72 and 73:

1 TIG WELDERS INVERTEC® V270-T AC/

- Page 74 and 75:

TIG WELDERS 1 Mastertig MLS TM 3000

- Page 76 and 77:

TIG WELDERS 1 MASTERTIG MLS 3000 AC

- Page 78 and 79:

TIG TORCHES AND SPARES 1 TM9 CONSUM

- Page 80 and 81:

TIG TORCHES AND SPARES 1 TM18 CONSU

- Page 82 and 83:

TIG TORCHES AND SPARES 1 TM24 CONSU

- Page 84 and 85:

TIG TORCHES AND SPARES 1 TIGMASTER

- Page 86 and 87:

TIG TORCHES AND SPARES 1 TIG WELDIN

- Page 88 and 89:

TIG TORCHES AND SPARES 1 TTC TIG-TO

- Page 90 and 91:

1 TIG TORCHES AND SPARES TUNGSTEN E

- Page 92 and 93:

1 MIG WELDERS WeldSkill 250 MIG Por

- Page 94 and 95:

20 3.6 MIG WELDERS 20 3.6 20 3.6 1

- Page 96 and 97:

20 3.6 MIG WELDERS 20 20 3.6 3.6 1

- Page 98 and 99:

MIG WELDERS 1 SYNERGIC PULSE Intell

- Page 100 and 101:

MIG WELDERS 20 3.6 20 3.6 20 3.6 1

- Page 102 and 103:

1 MIG WELDERS CV425 - CV510 Shown w

- Page 104 and 105:

MIG WELDERS 1 KEMPACT RA 181A, 251R

- Page 106 and 107:

MIG WELDERS 1 FASTMIG PULSE 350/450

- Page 108 and 109:

1 MIG WELDERS MAGTRAC F 61 Kemppi

- Page 110 and 111:

1 Wire guide tube Wire ø mm 0.6 0.

- Page 112 and 113:

MIG WELDERS 1 Weldmatic 190 Part No

- Page 114 and 115:

MIG TORCHES AND SPARES 1 WELDING EQ

- Page 116 and 117:

MIG TORCHES AND SPARES 1 TWECO® No

- Page 118 and 119:

MIG TORCHES AND SPARES 1 SPARE PART

- Page 120 and 121:

MIG TORCHES AND SPARES 1 CONTACT TI

- Page 122 and 123:

MIG TORCHES AND SPARES 1 TWECO® NO

- Page 124 and 125:

MIG TORCHES AND SPARES 1 MIG GUN LI

- Page 126 and 127:

MIG TORCHES AND SPARES 1 1150 SELF

- Page 128 and 129:

MIG TORCHES AND SPARES 1 PROFAX HEA

- Page 130 and 131:

MIG TORCHES AND SPARES 1 130GL SELF

- Page 132 and 133:

MIG TORCHES AND SPARES 1 PROFAX® R

- Page 134 and 135:

MIG TORCHES AND SPARES 1 CONSUMABLE

- Page 136 and 137:

MIG TORCHES AND SPARES 1 CONSUMABLE

- Page 138 and 139:

MIG TORCHES AND SPARES 1 CONSUMABLE

- Page 140 and 141:

MIG TORCHES AND SPARES 1 MIG/MAG WE

- Page 142 and 143:

MIG TORCHES AND SPARES 1 MIG/MAG WE

- Page 144 and 145:

MIG TORCHES AND SPARES 1 BERNARD MI

- Page 146 and 147:

MIG TORCHES AND SPARES 1 LINERS WIR

- Page 148 and 149:

MULTI-PROCESS WELDERS 20 3.6 20 3.6

- Page 150 and 151:

20 3.6 MULTI-PROCESS WELDERS 20 3.6

- Page 152 and 153:

20 3.6 MULTI-PROCESS WELDERS 20 20

- Page 154 and 155:

1 WELDING EQUIPMENT MULTI-PROCESS W

- Page 156 and 157:

MULTI-PROCESS WELDERS 20 3.6 20 3.6

- Page 158 and 159:

ENGINE DRIVEN WELDERS 20 3.6 1 OUTB

- Page 160 and 161:

ENGINE DRIVEN WELDERS 20 3.6 1 Vant

- Page 162 and 163:

1 WIRE FEEDERS TRANSMIG VA4000 Part

- Page 164 and 165:

WIRE FEEDERS 1 LF-72 and LF-74 Wire

- Page 166 and 167:

1 WIRE FEEDERS LN-25 PRO K2614-1 K2

- Page 168 and 169:

PLASMA 1 CUTSKILL 35A PLASMA INVERT

- Page 170 and 171:

1 WELDING EQUIPMENT PLASMA CUTMASTE

- Page 172 and 173:

PLASMA TORCHES AND SPARES 1 HAND TO

- Page 174 and 175:

PLASMA TORCHES AND SPARES 1 PLASMA

- Page 176 and 177:

PLASMA TORCHES AND SPARES 1 PCH/M-8

- Page 178 and 179:

PLASMA TORCHES AND SPARES 1 PCT 20

- Page 180 and 181:

PLASMA TORCHES AND SPARES 1 T100 TO

- Page 182 and 183:

PLASMA TORCHES AND SPARES 1 PT-25 P

- Page 184 and 185:

PLASMA TORCHES AND SPARES 1 PLASMA

- Page 186 and 187:

PURGING 1 ARGWELD INFLATABLE PIPE P

- Page 188 and 189:

PURGING 1 ARGWELD PIPE PURGE PLUGS

- Page 190 and 191:

PORTABLE OVENS 1 INDUSTRIAL WELDING

- Page 192 and 193:

SPECIALISED WELDERS 1 ROBOTS Purcha

- Page 194 and 195:

1 AUTOMATION BOA-408i S4 package Th

- Page 196 and 197:

AUTOMATION 1 TOOL POSITIONING SYSTE

- Page 198 and 199:

1 AUTOMATION SPEED WEAVER II The Sp

- Page 200 and 201:

AUTOMATION 1 BUG-GY FILLET WELDER A

- Page 202 and 203:

AUTOMATION 1 BENT RIGID RAILS (BRR)

- Page 204 and 205:

AUTOMATION 1 WELDING CHUCK Bigger w

- Page 206 and 207:

1 AUTOMATION VRX INTERNAL VRD The i

- Page 208 and 209:

AUTOMATION 1 FLUX RECOVERY MADE EA$

- Page 210 and 211:

AUTOMATION 1 SPS-1500 (11⁄2HP), S

- Page 212 and 213:

AUTOMATION 1 MAGNATECH 800 SERIES W

- Page 214 and 215:

AUTOMATION 1 MAGNATECH TUBESHEET WE

- Page 216 and 217:

1 AUTOMATION MAGNATECH PIPEMASTER 5

- Page 218 and 219:

1 AUTOMATION MAGNATECH PIPELINER II

- Page 220 and 221:

AUTOMATION 1 MAGNATECH WELDING TRAC

- Page 222 and 223:

KITS COMET EDGE CUSTOM 4 PACK 2 Par

- Page 224 and 225:

KITS REGULATORS - WELDING, CUTTING,

- Page 226 and 227:

KITS GAS EQUIPMENT TURBOTORCH® 2 E

- Page 228 and 229:

2 REGULATORS COMET EDGE ESS3 CO2 RE

- Page 230 and 231:

2 REGULATORS COMET EDGE ESS4 NITROG

- Page 232 and 233:

REGULATORS GENUINE COMET 5000 HIGH

- Page 234 and 235:

REGULATORS CUTSKILL OXYGEN REGULATO

- Page 236 and 237:

BLOWPIPES AND ATTACHMENTS GENUINE C

- Page 238 and 239:

BLOWPIPES AND ATTACHMENTS 2 GENUINE

- Page 240 and 241:

BLOWPIPES AND ATTACHMENTS 2 GENUINE

- Page 242 and 243:

CUTTING NOZZLES GENUINE COMET TYPE

- Page 244 and 245:

CUTTING NOZZLES CUTSKILL TYPE 41 CU

- Page 246 and 247:

WELDING AND HEATING GENUINE COMET O

- Page 248 and 249:

WELDING AND HEATING GENUINE COMET S

- Page 250 and 251:

HOSES AND FITTINGS FITTED HOSES AND

- Page 252 and 253:

HOSES AND FITTINGS TWIN GAS HOSES (

- Page 254 and 255:

2 ACCESSORIES GENUINE COMET FLASHBA

- Page 256 and 257:

ACCESSORIES FLINT LIGHTER Metal Cup

- Page 258 and 259:

MACHINES 2 PIPEMATE Specifications

- Page 260 and 261:

GAS HEATING HANDPIECE 2 EXPANSION B

- Page 262 and 263:

GAS HEATING SIEVERT FLOWCHART 2 NEC

- Page 264 and 265:

INDUSTRIAL GASES These pages have b

- Page 266 and 267:

GASES Shielding gas selection chart

- Page 268 and 269:

GASES SHIELDING GASES 3 MCW INDUSTR

- Page 270 and 271:

GASES SHIELDING GASES 3 Heavy INDUS

- Page 272 and 273:

GASES SHIELDING GASES Copper INDUST

- Page 274 and 275:

RESPIRATORY CLEANSPACE2 POWERED RES

- Page 276 and 277:

RESPIRATORY PROTECTION REUSABLE RES

- Page 278 and 279:

HEAD AND FACE 3M VERSAFLO FACE SHIE

- Page 280 and 281:

HEAD AND FACE HELMETS AND PARTS D63

- Page 282 and 283:

HEAD AND FACE HIDEROK WELDING HELME

- Page 284 and 285:

HEAD AND FACE WELDING GOGGLES PART

- Page 286 and 287:

HEAD AND FACE DISPOSABLE & REUSABLE

- Page 288 and 289:

HEAD AND FACE 3M VERSAFLO 4 3M VERS

- Page 290 and 291:

HEAD AND FACE WORKPLACE EYEWEAR UVE

- Page 292 and 293:

HEAD AND FACE WORKPLACE EYEWEAR UVE

- Page 294 and 295:

HEAD AND FACE UVEX EYEWEAR ACCESSOR

- Page 296 and 297:

HEAD AND FACE WORKPLACE EYEWEAR ONI

- Page 298 and 299:

HAND PROTECTION MARKING AS PER AS/N

- Page 300 and 301:

HAND PROTECTION GLOVES RIGGER GLOVE

- Page 302 and 303:

HAND PROTECTION WELDING GLOVES SUPE

- Page 304 and 305:

HAND PROTECTION KEVLAR® HEAT PROTE

- Page 306 and 307:

WELDING & GENERAL APPAREL CHROME LE

- Page 308 and 309:

WELDING & GENERAL APPAREL BIG RED®

- Page 310 and 311:

WELDING & GENERAL APPAREL WAKATAC S

- Page 312 and 313:

WELDING & GENERAL APPAREL CHROME LE

- Page 314 and 315:

WELDING BLANKETS & DRAPES WELDING D

- Page 316 and 317:

FUME EQUIPMENT MINIVEYOR AIR VAF CO

- Page 318 and 319:

ELECTRODES MILD STEEL & IRON POWDER

- Page 320 and 321:

ELECTRODES MILD STEEL & IRON POWDER

- Page 322 and 323:

ELECTRODES MILD STEEL & IRON POWDER

- Page 324 and 325:

ELECTRODES MILD STEEL & IRON POWDER

- Page 326 and 327:

ELECTRODES MILD STEEL & IRON POWDER

- Page 328 and 329:

ELECTRODES LOW HYDROGEN 5 FERROCRAF

- Page 330 and 331:

ELECTRODES LOW HYDROGEN FERROCRAFT

- Page 332 and 333:

ELECTRODES LOW HYDROGEN ALLOYCRAFT

- Page 334 and 335:

ELECTRODES LOW HYDROGEN EASYARC TM

- Page 336 and 337:

ELECTRODES LOW HYDROGEN KRYO® 3 Lo

- Page 338 and 339:

ELECTRODES LOW HYDROGEN KOBE ELECTR

- Page 340 and 341:

ELECTRODES LOW HYDROGEN OK 53.70 Ty

- Page 342 and 343:

ELECTRODES LOW HYDROGEN OK 74.46 (N

- Page 344 and 345:

ELECTRODES LOW HYDROGEN OK 76.18 Ty

- Page 346 and 347:

ELECTRODES LOW HYDROGEN AUSTARC 16T

- Page 348 and 349:

ELECTRODES STAINLESS STEEL & SPECIA

- Page 350 and 351:

ELECTRODES STAINLESS STEEL & SPECIA

- Page 352 and 353:

ELECTRODES STAINLESS STEEL & SPECIA

- Page 354 and 355: ELECTRODES STAINLESS STEEL & SPECIA

- Page 356 and 357: ELECTRODES STAINLESS STEEL & SPECIA

- Page 358 and 359: ELECTRODES STAINLESS STEEL & SPECIA

- Page 360 and 361: ELECTRODES STAINLESS STEEL & SPECIA

- Page 362 and 363: ELECTRODES HARD FACING COBALARC AUS

- Page 364 and 365: ELECTRODES HARD FACING 5 COBALARC 7

- Page 366 and 367: ELECTRODES HARD FACING 5 STOODY TUB

- Page 368 and 369: WIRES MIG AUTOCRAFT LW1 ALL POSITIO

- Page 370 and 371: WIRES MIG AUTOCRAFT MN-MO ALL POSIT

- Page 372 and 373: WIRES MIG AUTOCRAFT 309LSi ALL POSI

- Page 374 and 375: WIRES MIG AUTOCRAFT AL5356 ALL POSI

- Page 376 and 377: WIRES MIG 5 CONSUMABLES 374 AVESTA

- Page 378 and 379: WIRES MIG SM-70 CO 2 /Ar+CO 2 5 AWS

- Page 380 and 381: WIRES MIG SM-308L AWS A5.9 / ASME S

- Page 382 and 383: WIRES MIG LINCOLN 308LSi Designed f

- Page 384 and 385: WIRES FLUX CORED SATIN-COR XP 5 Sat

- Page 386 and 387: 5 WIRES FLUX CORED VERTI-COR 3XP Ve

- Page 388 and 389: 5 WIRES FLUX CORED VERTI-COR 111 K3

- Page 390 and 391: WIRES FLUX CORED NICORE® 55 5 Nico

- Page 392 and 393: WIRES FLUX CORED STOODY SOS 308L 5

- Page 394 and 395: (Gas Shielded) FLUX CORED WIRES OUT

- Page 396 and 397: WIRES FLUX CORED INNERSHIELD® NR-2

- Page 398 and 399: WIRES FLUX CORED KOBE FLUX CORED WI

- Page 400 and 401: WIRES FLUX CORED SF-71 CO 2 5 AWS A

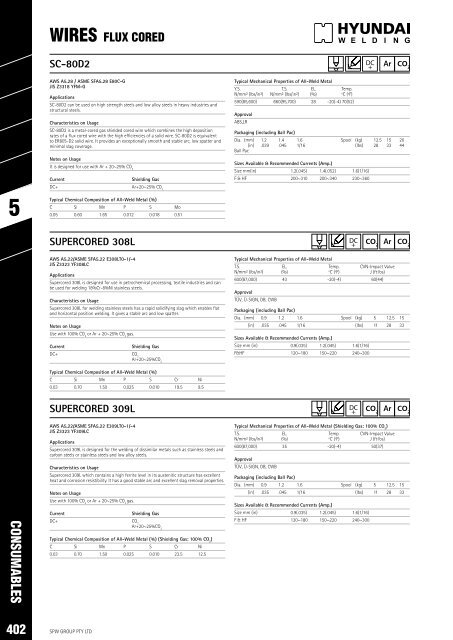

- Page 402 and 403: WIRES FLUX CORED SUPERCORED 70B CO

- Page 406 and 407: WIRES FLUX CORED DUAL SHIELD 7100 A

- Page 408 and 409: WIRES FLUX CORED DUAL SHIELD II 110

- Page 410 and 411: WIRES FLUX CORED COREWELD 111 ULTRA

- Page 412 and 413: WIRES FLUX CORED SHIELD-BRIGHT 308L

- Page 414 and 415: WIRES FLUX CORED SHIELD-BRIGHT 316L

- Page 416 and 417: WIRES HARD FACING 5 STOODY DYNAMANG

- Page 418 and 419: WIRES HARD FACING 5 STOODY 101 HC-G

- Page 420 and 421: WIRES HARD FACING LINCORE® 33 Prov

- Page 422 and 423: WIRES HARD FACING LINCORE® 60-O Re

- Page 424 and 425: SUB ARC WIRES AND FLUXES AUTOCRAFT

- Page 426 and 427: SUB ARC WIRES AND FLUXES QR-8045 Al

- Page 428 and 429: SUB ARC WIRES AND FLUXES LINCOLNWEL

- Page 430 and 431: SUB ARC WIRES AND FLUXES 8500 A hig

- Page 432 and 433: SUB ARC WIRES AND FLUXES 5 CONSUMAB

- Page 434 and 435: SUB ARC WIRES AND FLUXES OK FLUX 10

- Page 436 and 437: SUB ARC WIRES AND FLUXES OK FLUX 10

- Page 438 and 439: SUB ARC WIRES AND FLUXES OK AUTROD

- Page 440 and 441: GAS AND TIG CONSUMABLES COMWELD LW1

- Page 442 and 443: GAS AND TIG CONSUMABLES COMWELD CRM

- Page 444 and 445: GAS AND TIG CONSUMABLES COMWELD AL1

- Page 446 and 447: GAS AND TIG CONSUMABLES COMWELD GEN

- Page 448 and 449: GAS AND TIG CONSUMABLES COMWELD TOB

- Page 450 and 451: GAS AND TIG CONSUMABLES COMWELD SIL

- Page 452 and 453: GAS AND TIG CONSUMABLES LINCOLN 446

- Page 454 and 455:

GAS AND TIG CONSUMABLES AVESTA STAN

- Page 456 and 457:

ABRASIVES FLAT METAL CUTTING OFF WH

- Page 458 and 459:

ABRASIVES METAL DEPRESSED CENTRE GR

- Page 460 and 461:

ABRASIVES INDUSTRIAL WIRE BRUSHES T

- Page 462 and 463:

ABRASIVES INDUSTRIAL COATED ABRASIV

- Page 464 and 465:

ABRASIVES INDUSTRIAL COATED ABRASIV

- Page 466 and 467:

OTHER COMWELD 965 SOLDER (SOFT SILV

- Page 468 and 469:

OTHER COMWELD 965 SOLDERING FLUX CO

- Page 470 and 471:

CHEMICAL PRODUCTS AVESTA REDONE 240

- Page 472 and 473:

CHEMICAL PRODUCTS 5 Avesta RedOne 1

- Page 474 and 475:

TERMS & DEFINITIONS TERMS AND DEFIN

- Page 476 and 477:

WELDING TYPES, POSITIONS & DEFECTS

- Page 478 and 479:

WELDING TYPES, POSITIONS & DEFECTS

- Page 480 and 481:

WELDING TYPES, POSITIONS & DEFECTS

- Page 482 and 483:

WELDING TYPES, POSITIONS & DEFECTS

- Page 484 and 485:

WELDING TYPES, POSITIONS & DEFECTS

- Page 486 and 487:

SAFETY IN WELDING A) ARC RADIATION

- Page 488 and 489:

CONSUMABLES CLASSIFICATION TABLES A

- Page 490 and 491:

CONSUMABLES CLASSIFICATION TABLES A

- Page 492 and 493:

CONSUMABLES CLASSIFICATION TABLES A

- Page 494 and 495:

CONSUMABLES CLASSIFICATION TABLES A

- Page 496 and 497:

CONSUMABLES CLASSIFICATION TABLES A

- Page 498 and 499:

CONSUMABLES CLASSIFICATION TABLES A

- Page 500 and 501:

CONSUMABLES CLASSIFICATION TABLES A

- Page 502 and 503:

WELDING GUIDE GENERAL PROCEDURE IN

- Page 504 and 505:

WELDING GUIDE PREHEAT DETERMINATION

- Page 506 and 507:

WELDING GUIDE STEEL SPECIFICATIONS

- Page 508 and 509:

WELDING GUIDE STEEL SPECIFICATIONS

- Page 510 and 511:

WELDING GUIDE STEEL SPECIFICATIONS

- Page 512 and 513:

WELDING GUIDE WELDING RECOMMENDATIO

- Page 514 and 515:

WELDING GUIDE CONSUMABLES FOR WELDI

- Page 516 and 517:

WELDING GUIDE AUSTENITIC STAINLESS

- Page 518 and 519:

WELDING GUIDE HEAT INPUT When the w

- Page 520 and 521:

WELDING GUIDE SCHAEFFLER AND DE LON

- Page 522 and 523:

WELDING GUIDE DEW POINT CONDITIONS

- Page 524 and 525:

WELDING GUIDE 3) FEEDABILITY OF ALU

- Page 526 and 527:

WELDING GUIDE 4) SMOKE TESTING ALUM

- Page 528 and 529:

WELDING GUIDE 5) ARC LENGTH & HEAT

- Page 530 and 531:

WELDING GUIDE ALUMINIUM ALLOY SELEC

- Page 532 and 533:

WELDING GUIDE 1) ALUMINIUM BASE MET

- Page 534 and 535:

WELDING GUIDE 2) TUNGSTEN ELECTRODE

- Page 536 and 537:

WELDING GUIDE 5) GTAW (TIG) TECHNIQ

- Page 538 and 539:

WELDING GUIDE TYPES OF CAST IRON CO

- Page 540 and 541:

WELDING GUIDE PRECAUTIONS WHEN WELD

- Page 542 and 543:

WELDING GUIDE SG CAST IRON Grey iro

- Page 544 and 545:

WELDING GUIDE 1) TYPES OF COPPER AL

- Page 546 and 547:

WELDING GUIDE 3) GAS METAL ARC WELD

- Page 548 and 549:

WELDING GUIDE 7) BRAZE WELDING OF C

- Page 550 and 551:

HARDFACING INFORMATION WHAT IS HARD

- Page 552 and 553:

HARDFACING INFORMATION HOW TO CHOOS

- Page 554 and 555:

HARDFACING INFORMATION COBALARC PRO

- Page 556 and 557:

HARDFACING INFORMATION COBALARC APP

- Page 558 and 559:

HARDFACING INFORMATION USE OF BUFFE

- Page 560 and 561:

WELD COSTINGS COSTING INFORMATION:

- Page 562 and 563:

DEPOSITION DATA GENERAL PROCESS EFF

- Page 564 and 565:

DEPOSITION DATA SQUARE BUTT JOINTS,

- Page 566 and 567:

FACTS & FIGURES MATHEMATICAL SYMBOL

- Page 568 and 569:

FACTS & FIGURES COMMON WELDING CONV

- Page 570 and 571:

FACTS & FIGURES CONVERSION TABLES -

- Page 572 and 573:

FACTS & FIGURES COMWELD RODS PER KG

- Page 574 and 575:

FACTS & FIGURES MASSES OF COMMON ME

- Page 576 and 577:

FACTS & FIGURES TEMPERATURE CONVERS

- Page 578 and 579:

FACTS & FIGURES GAS PRESSURES - GAS

- Page 580 and 581:

INFORMATION CONNECTORS SHELL Shell

- Page 582 and 583:

6 WARRANTY DATA LINCOLN ELECTRIC AU

- Page 584 and 585:

6 TECHNICAL 582 SPW GROUP PTY LTD

- Page 586 and 587:

IMPORTANT SAFETY INFORMATION IMPORT

- Page 588 and 589:

Guarantee and indemnity i/We: (here

- Page 590 and 591:

General terms and conditions of Sup

- Page 592 and 593:

NOTES 590 SPW GROUP PTY LTD

- Page 594 and 595:

NOTES 592 SPW GROUP PTY LTD

- Page 596:

WE HAVE THE BEST WELDING EQUIPMENT