SPW Product Catalogue 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

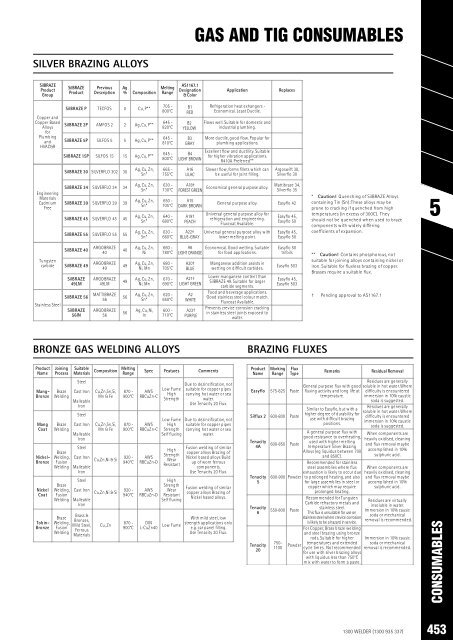

GAS AND TIG CONSUMABLES<br />

SILVER BRAZING ALLOYS<br />

SilBRAZE<br />

<strong>Product</strong><br />

Group<br />

SilBRAZE<br />

<strong>Product</strong><br />

Previous<br />

Description<br />

Ag<br />

% Composition<br />

Melting<br />

Range<br />

AS1167.1<br />

Designation<br />

&Color<br />

Application<br />

Replaces<br />

Copper and<br />

Copper Based<br />

Alloys<br />

for<br />

Plumbing<br />

and<br />

HVAC&R<br />

SilBRAZE P TECFOS 0 Cu, P**<br />

SilBRAZE 2P AMFOS2 2 Ag, Cu,P**<br />

SilBRAZE 5P SILFOS 5 5 Ag,Cu, P**<br />

SilBRAZE 15P SILFOS 15 15 Ag,Cu, P**<br />

SilBRAZE 30 SILVERFLO302 30<br />

Ag,Cu, Zn,<br />

Sn*<br />

705 -<br />

800°C<br />

645 -<br />

820°C<br />

645 -<br />

810°C<br />

645 -<br />

800°C<br />

665 -<br />

755°C<br />

B1<br />

RED<br />

B2<br />

YELLOW<br />

B3<br />

GRAY<br />

Refrigeration heatexhangers -<br />

Economical.Least Ductile.<br />

Flowswell. Suitable for domestic and<br />

industrial plumbing.<br />

More ductile,good flow.Popular for<br />

plumbing applications.<br />

B4<br />

Excellentflow and ductility. Suitable<br />

for highervibration applications.<br />

LIGHT BROWN<br />

R410A Preferred**<br />

A16<br />

LILAC<br />

Slower flow,forms filletswhich can<br />

be useful for joint filling.<br />

Argoswift 30,<br />

Silverflo 30<br />

Engineering<br />

Materials<br />

Cadmium<br />

Free<br />

SilBRAZE 34 SILVERFLO34 34<br />

SilBRAZE 39 SILVERFLO39 39<br />

SilBRAZE 45 SILVERFLO45 45<br />

SilBRAZE 55 SILVERFLO55 55<br />

Ag,Cu, Zn,<br />

Sn*<br />

Ag,Cu, Zn,<br />

Sn*<br />

Ag,Cu, Zn,<br />

Sn*<br />

Ag,Cu, Zn,<br />

Sn*<br />

630 -<br />

730°C<br />

650 -<br />

705°C<br />

640 -<br />

680°C<br />

630 -<br />

660°C<br />

A18†<br />

FOREST GREEN Economical general purpose alloy. Mattibraze 34,<br />

Silverflo 35<br />

A15<br />

DARK BROWN<br />

A19†<br />

PEACH<br />

A22†<br />

BLUE-GRAY<br />

General purpose alloy. Easyflo 42<br />

Universal general purposealloy for<br />

refrigeration and engineering.<br />

Fluxcoat Available.<br />

Universal general purposealloy with<br />

lowermelting point.<br />

Easyflo 45,<br />

Easyflo 50<br />

Easyflo 45,<br />

Easyflo 50<br />

* Caution! Quenching ofSilBRAZEAlloys<br />

containing Tin(Sn):Thesealloysmay be<br />

pronetocracking ifquenched from high<br />

temperatures (in excessof300C). They<br />

should notbequenched when used tobraze<br />

components with widely differing<br />

coefficients of expansion.<br />

5<br />

Tungsten<br />

carbide<br />

StainlessSteel<br />

SilBRAZE 40<br />

SilBRAZE 49<br />

SilBRAZE<br />

49LM<br />

SilBRAZE 56<br />

SilBRAZE<br />

56IN<br />

ARGOBRAZE<br />

40<br />

ARGOBRAZE<br />

49<br />

ARGOBRAZE<br />

49LM<br />

MATTIBRAZE<br />

56<br />

ARGOBRAZE<br />

56<br />

40<br />

49<br />

49<br />

56<br />

56<br />

Ag,Cu, Zn,<br />

Ni<br />

Ag,Cu, Zn,<br />

Ni,Mn<br />

Ag,Cu, Zn,<br />

Ni,Mn<br />

Ag,Cu, Zn,<br />

Sn*<br />

Ag,Cu,Ni,<br />

In<br />

660 -<br />

780°C<br />

680 -<br />

705°C<br />

670 -<br />

690°C<br />

620 -<br />

650°C<br />

600 -<br />

710°C<br />

A8 Economical.Goodwetting.Suitable<br />

LIGHT ORANGE for food applications.<br />

A20†<br />

BLUE<br />

A21†<br />

LIGHT GREEN<br />

A2<br />

WHITE<br />

A23†<br />

PURPLE<br />

Manganeseaddition assists in<br />

wetting ondifficult carbides.<br />

Lowermanganese contentthan<br />

SilBRAZE 49.Suitablefor larger<br />

carbide segments.<br />

Food and beverage applications.<br />

Good stainlesssteel colour match.<br />

Fluxcoat Available.<br />

Prevents crevice corrosion cracking<br />

in stainlesssteel joints exposed to<br />

water.<br />

Easyflo 50<br />

trifoils<br />

Easyflo 503<br />

Easyflo 45,<br />

Easyflo 503<br />

** Caution! Contains phosphorous, not<br />

suitable forjoining alloys containing nickel or<br />

iron.Suitablefor fluxless brazing ofcopper.<br />

Brasses require asuitableflux.<br />

† Pending approval to AS1167.1<br />

BRONZE GAS WELDING ALLOYS<br />

BRAZING FLUXES<br />

<strong>Product</strong><br />

Name<br />

Mang-<br />

Bronze<br />

Mang<br />

Coat<br />

Nickel-<br />

Bronze<br />

Nickel<br />

Coat<br />

Tobin-<br />

Bronze<br />

Joining<br />

Process<br />

Braze<br />

Welding<br />

Braze<br />

Welding<br />

Braze<br />

Welding,<br />

Fusion<br />

Welding<br />

Braze<br />

Welding,<br />

Fusion<br />

Welding<br />

Braze<br />

Welding,<br />

Fusion<br />

Welding<br />

Suitable<br />

Materials<br />

Steel<br />

Cast Iron<br />

Malleable<br />

Iron<br />

Steel<br />

Cast Iron<br />

Malleable<br />

Iron<br />

Steel<br />

Cast Iron<br />

Malleable<br />

Iron<br />

Steel<br />

Cast Iron<br />

Malleable<br />

Iron<br />

Brass &<br />

Bronzes,<br />

Mild Steel,<br />

Ferrous<br />

Materials<br />

Composition<br />

Cu,Zn,Sn,Si,<br />

Mn &Fe<br />

Cu,Zn,Sn,Si,<br />

Mn &Fe<br />

Cu,Zn,Ni &Si<br />

Cu,Zn,Ni &Si<br />

Cu,Zn<br />

Melting<br />

Range<br />

870 -<br />

900°C<br />

870 -<br />

900°C<br />

920 -<br />

940°C<br />

920 -<br />

940°C<br />

870 -<br />

900°C<br />

Spec Features Comments<br />

AWS<br />

RBCuZn-C<br />

AWS<br />

RBCuZn-C<br />

AWS<br />

RBCuZn-D<br />

AWS<br />

RBCuZn-D<br />

DIN<br />

L-CuZn40<br />

LowFume<br />

High<br />

Strength<br />

LowFume<br />

High<br />

Strength<br />

Self fluxing<br />

High<br />

Strength<br />

Wear<br />

Resistant<br />

High<br />

Strength<br />

Wear<br />

Resistant<br />

Self fluxing<br />

LowFume<br />

Duetodezincification,not<br />

suitable for copperpipes<br />

carrying hotwater or sea<br />

water.<br />

Use Tenacity 20Flux.<br />

Duetodezincification,not<br />

suitable forcopperpipes<br />

carrying hotwater or sea<br />

water.<br />

Fusion welding ofsimilar<br />

copper alloys Brazing of<br />

Nickel based alloys Build<br />

up of worn ferrous<br />

components.<br />

Use Tenacity 20Flux.<br />

Fusion welding ofsimilar<br />

copper alloys Brazing of<br />

Nickel based alloys.<br />

With mild steel, low<br />

strength applications only<br />

e.g.carpanel filling.<br />

Use Tenacity 20Flux.<br />

<strong>Product</strong><br />

Name<br />

Working<br />

Range<br />

Flux<br />

Type<br />

Easyflo 575-825 Paste<br />

Silflux 2 600-800 Paste<br />

Tenacity<br />

4A<br />

Tenacity<br />

5<br />

Tenacity<br />

6<br />

Tenacity<br />

20<br />

600-850 Paste<br />

600-900 Powder<br />

550-800 Paste<br />

750-<br />

1100<br />

Remarks<br />

Generalpurpose flux with good<br />

fluxing activity and long life at<br />

temperature.<br />

SimilartoEasyflo,but with a<br />

higher degree of durability for<br />

use with difficult brazing<br />

positions.<br />

ResidualRemoval<br />

Residues are generally<br />

solubleinhot water. Where<br />

difficulty is encountered<br />

immersion in10% caustic<br />

soda is suggested.<br />

Residues are generally<br />

solubleinhot water. Where<br />

difficulty is encountered<br />

immersion in10% caustic<br />

soda is suggested.<br />

Ageneral purposeflux with When components are<br />

good resistance to overheating, heavily oxidised, cleaning<br />

used with higher melting<br />

and flux removal maybe<br />

temperature SilverBrazing<br />

Alloys (eg liquidusbetween 700<br />

accomplished in 10%<br />

and 850C).<br />

sulphuric acid.<br />

Recommendedfor stainless<br />

steelassemblies where flux<br />

exhaustion is likely to occurdue<br />

to prolongedheating,and also<br />

forlarge assemblies in steel or<br />

copper which may require<br />

prolongedheating.<br />

When components are<br />

heavily oxidised, cleaning<br />

and flux removal maybe<br />

accomplished in 10%<br />

sulphuric acid.<br />

Recommendedfor Tungsten<br />

Residues are virtually<br />

Carbide refractorymetals and<br />

insolubleinwater.<br />

stainlesssteel.<br />

This flux is unsuitable foruse on<br />

Immersion in10% causic<br />

stainlesssteelwherecrevice corrosion<br />

soda or mechanical<br />

is likely to be ahazardinservice.<br />

removalisrecommended.<br />

ForCopper, Brass braze welding<br />

and steel brazing using bronze<br />

rods.Suitablefor higher Immersion in10% causic<br />

temperatures and extended<br />

Powder<br />

soda or mechanical<br />

cycle times. Not recommended removalisrecommended.<br />

foruse with silver brazing alloys<br />

with liquidus less than 750°C<br />

mixwith water to form apaste.<br />

CONSUMABLES<br />

1300 WELDER (1300 935 337)<br />

453