SPW Product Catalogue 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

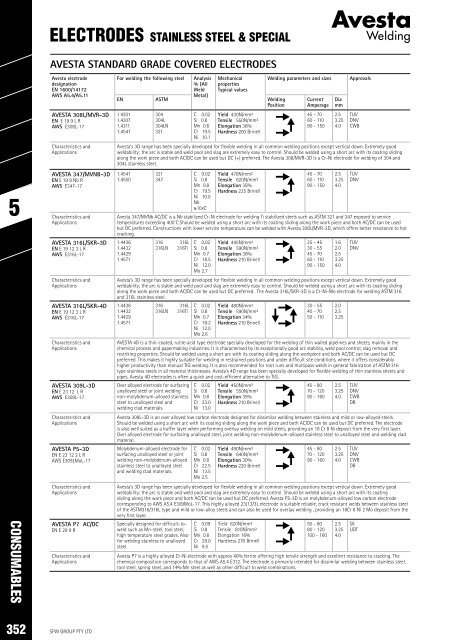

ELECTRODES STAINLESS STEEL & SPECIAL<br />

AVESTA STANDARD GRADE COVERED ELECTRODES<br />

5<br />

CONSUMABLES<br />

Avesta electrode<br />

designation<br />

EN 1600/14172<br />

AWS A5.4/A5.11<br />

AVESTA 308L/MVR-3D<br />

EN E 19 9 L R<br />

AWS E308L-17<br />

Characteristics and<br />

Applications<br />

AVESTA 347/MVNB-3D<br />

EN E 19 9 Nb R<br />

AWS E347-17<br />

Characteristics and<br />

Applications<br />

AVESTA 316L/SKR-3D<br />

EN E 19 12 3 L R<br />

AWS E316L-17<br />

Characteristics and<br />

Applications<br />

AVESTA 316L/SKR-4D<br />

EN E 19 12 3 L R<br />

AWS E316L-17<br />

Characteristics and<br />

Applications<br />

AVESTA 309L-3D<br />

EN E 23 12 L R<br />

AWS E309L-17<br />

Characteristics and<br />

Applications<br />

AVESTA P5-3D<br />

EN E 23 12 2 L R<br />

AWS E309LMoL-17<br />

Characteristics and<br />

Applications<br />

AVESTA P7 AC/DC<br />

EN E 29 9 R<br />

Characteristics and<br />

Applications<br />

For welding the following steel<br />

Analysis<br />

% (All<br />

Weld<br />

Metal)<br />

Mechanical<br />

properties<br />

Typical values<br />

EN ASTM Welding<br />

Position<br />

1.4301<br />

1.4307<br />

1.4311<br />

1.4541<br />

304<br />

304L<br />

304LN<br />

321<br />

C 0.02<br />

Si 0.8<br />

Mn 0.6<br />

Cr 19.5<br />

Ni 10.1<br />

Yield 430N/mm²<br />

Tensile 550N/mm²<br />

Elongation 36%<br />

Hardness 200 Brinell<br />

Welding parameters and sizes<br />

Current<br />

Amperage<br />

45 - 70<br />

60 - 110<br />

90 - 150<br />

Dia<br />

mm<br />

2.5<br />

3.25<br />

4.0<br />

Approvals<br />

Avesta’s 3D range has been specially developed for flexible welding in all common welding positions except vertical down. Extremely good<br />

weldability; the arc is stable and weld pool and slag are extremely easy to control. Should be welded using a short arc with its coating sliding<br />

along the work piece and both AC/DC can be used but DC (+) preferred. The Avesta 308/MVR-3D is a Cr-Ni electrode for welding of 304 and<br />

304L stainless steel.<br />

1.4541<br />

1.4550<br />

321<br />

347<br />

C 0.02<br />

Si 0.8<br />

Mn 0.8<br />

Cr 19.5<br />

Ni 10.0<br />

Nb<br />

≥10xC<br />

Yield 470N/mm²<br />

Tensile 620N/mm²<br />

Elongation 35%<br />

Hardness 225 Brinell<br />

45 - 70<br />

60 - 110<br />

90 - 150<br />

Avesta 347/MVNb AC/DC is a Nb stabilized Cr-Ni electrode for welding Ti stabilized steels such as ASTM 321 and 347 exposed to service<br />

temperatures exceeding 400˚C.Should be welded using a short arc with its coating sliding along the work piece and both AC/DC can be used<br />

but DC preferred. Constructions with lower service temperature can be welded with Avesta 308L/MVR-3D, which offers better resistance to hot<br />

cracking.<br />

1.4436<br />

1.4432<br />

1.4429<br />

1.4571<br />

316 316L<br />

316LN 316Ti<br />

C 0.02<br />

Si 0.8<br />

Mn 0.7<br />

Cr 18.5<br />

Ni 12.0<br />

Mo 2.7<br />

Yield 445N/mm²<br />

Tensile 590N/mm²<br />

Elongation 36%<br />

Hardness 210 Brinell<br />

25 - 45<br />

30 - 55<br />

45 - 70<br />

60 - 110<br />

90 - 150<br />

Avesta’s 3D range has been specially developed for flexible welding in all common welding positions except vertical down. Extremely good<br />

weldability; the arc is stable and weld pool and slag are extremely easy to control. Should be welded using a short arc with its coating sliding<br />

along the work piece and both AC/DC can be used but DC preferred. The Avesta 316L/SKR-3D is a Cr-Ni-Mo electrode for welding ASTM 316<br />

and 316L stainless steel.<br />

1.4436<br />

1.4432<br />

1.4429<br />

1.4571<br />

316 316L<br />

316LN 316Ti<br />

C 0.02<br />

Si 0.8<br />

Mn 0.7<br />

Cr 18.2<br />

Ni 12.0<br />

Mo 2.6<br />

Yield 480N/mm²<br />

Tensile 590N/mm²<br />

Elongation 34%<br />

Hardness 210 Brinell<br />

30 - 55<br />

40 - 70<br />

50 - 110<br />

AVESTA 4D is a thin-coated, rutile-acid type electrode specially developed for the welding of thin walled pipelines and sheets, mainly in the<br />

chemical process and papermaking industries. It is characterised by its exceptionally good arc stability, weld pool control, slag removal and<br />

restriking properties. Should be welded using a short arc with its coating sliding along the workpiece and both AC/DC can be used but DC<br />

preferred. This makes it highly suitable for welding in restrained positions and under difficult site conditions, where it offers considerably<br />

higher productivity than manual TIG welding. It is also recommended for root runs and multipass welds in general fabrication of ASTM 316<br />

type stainless steels in all material thicknesses. Avesta’s 4D range has been specially developed for flexible welding of thin stainless sheets and<br />

pipes. Avesta 4D electrodes is often a quick and cost-efficient alternative to TIG.<br />

Over alloyed electrode for surfacing<br />

unalloyed steel or joint welding<br />

non-molybdenum-alloyed stainless<br />

steel to unalloyed steel and<br />

welding clad materials.<br />

C 0.02<br />

Si 0.8<br />

Mn 0.8<br />

Cr 23.0<br />

Ni 13.0<br />

Yield 450N/mm²<br />

Tensile 550N/mm²<br />

Elongation 35%<br />

Hardness 210 Brinell<br />

45 - 80<br />

70 - 120<br />

90 - 160<br />

Avesta 309L-3D is an over alloyed low carbon electrode designed for dissimilar welding between stainless and mild or low-alloyed steels.<br />

Should be welded using a short arc with its coating sliding along the work piece and both AC/DC can be used but DC preferred. The electrode<br />

is also well suited as a buffer layer when performing overlay welding on mild steels, providing an 18 Cr 8 Ni deposit from the very first layer.<br />

Over alloyed electrode for surfacing unalloyed steel, joint welding non-molybdenum-alloyed stainless steel to unalloyed steel and welding clad<br />

material.<br />

Molybdenum-alloyed electrode for<br />

surfacing unalloyed steel or joint<br />

welding non-molybdenum-alloyed<br />

stainless steel to unalloyed steel<br />

and welding clad materials.<br />

C 0.02<br />

Si 0.8<br />

Mn 0.8<br />

Cr 22.5<br />

Ni 13.5<br />

Mo 2.5<br />

Yield 490N/mm²<br />

Tensile 640N/mm²<br />

Elongation 30%<br />

Hardness 220 Brinell<br />

45 - 80<br />

70 - 120<br />

90 - 160<br />

Avesta’s 3D range has been specially developed for flexible welding in all common welding positions except vertical down. Extremely good<br />

weldability; the arc is stable and weld pool and slag are extremely easy to control. Should be welded using a short arc with its coating<br />

sliding along the work piece and both AC/DC can be used but DC preferred. Avesta P5-3D is an molybdenum-alloyed low carbon electrode<br />

corresponding to AWS A5.4 E309MoL-17. This highly alloyed 23/13/3L electrode is suitable reliable, crack resistant welds between stainless steel<br />

of the ASTM316/316L type and mild or low-alloy steels and can also be used for overlay welding , providing an 18Cr 8 Ni 2 Mo deposit from the<br />

very first layer.<br />

Specially designed for difficult-toweld<br />

such as Mn-steel, tool steel,<br />

high temperature steel grades. Also<br />

for welding stainless to unalloyed<br />

steel.<br />

C 0.09<br />

Si 0.8<br />

Mn 0.8<br />

Cr 29.0<br />

Ni 9.5<br />

Yield 620N/mm²<br />

Tensile 810N/mm²<br />

Elongation 16%<br />

Hardness 270 Brinell<br />

50 - 80<br />

80 - 120<br />

100 - 160<br />

Avesta P7 is a highly alloyed Cr-Ni electrode with approx 40% ferrite offering high tensile strength and excellent resistance to cracking. The<br />

chemical composition corresponds to that of AWS A5.4 E312. The electrode is primarily intended for dissimilar welding between stainless steel,<br />

tool steel, spring steel, and 14% Mn steel as well as other difficult to weld combinations.<br />

2.5<br />

3.25<br />

4.0<br />

1.6<br />

2.0<br />

2.5<br />

3.25<br />

4.0<br />

2.0<br />

2.5<br />

3.25<br />

2.5<br />

3.25<br />

4.0<br />

2.5<br />

3.25<br />

4.0<br />

2.5<br />

3.25<br />

4.0<br />

TUV<br />

DNV<br />

CWB<br />

TUV<br />

DNV<br />

TUV<br />

DNV<br />

TUV<br />

DNV<br />

CWB<br />

DB<br />

TUV<br />

DNV<br />

CWB<br />

DB<br />

SK<br />

UDT<br />

352<br />

<strong>SPW</strong> GROUP PTY LTD