SPW Product Catalogue 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

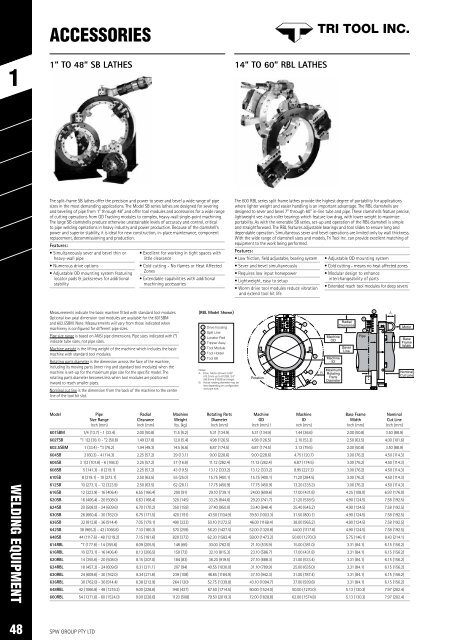

ACCESSORIES<br />

TRI TOOL INC.<br />

1<br />

1” TO 48” SB LATHES 14” TO 60” RBL LATHES<br />

The split-frame SB lathes offer the precision and power to sever and bevel a wide range of pipe The 600 RBL series split frame lathes provide the highest degree of portability for applications<br />

sizes in the most demanding applications. The Model SB series lathes are designed for (Model severing 602 SBCM Shown)<br />

4<br />

4<br />

where lighter weight and easier handling is an important advantage. The RBL clamshells are<br />

and beveling of pipe from 1” through 48” and offer tool modules and accessories for a wide range designed to sever and bevel 7” through 60” in-line tube and pipe. These clamshells feature precise,<br />

of cutting operations from OD Tracking modules to complex, heavy-wall single-point 1 machining. Drive housing lightweight vee-track 1 roller bearings which feature low drag, with lower weight to maximize<br />

The large SB clamshells produce otherwise unattainable levels of accuracy and control, 2 critical Split Line portability. As with the venerable SB series, set-up and operation of the RBL clamshell is simple<br />

to pipe welding operations in heavy industry and power production. Because of the clamshell’s<br />

3 Drive Input and straightforward. The RBL features adjustable bearings and tool 3 slides to ensure long and 3<br />

power and superior stability, it is ideal for new construction, in-place maintenance, component<br />

4 Tripper Assy. dependable Rotating operation. Simultaneous sever and bevel operations are limited only by wall thickness.<br />

replacement, decommissioning and production.<br />

5 Collet With<br />

Parts<br />

the<br />

Dia.<br />

wide range of clamshell sizes and models, Tri Tool Inc. can provide 6 excellent matching of<br />

6 Tool Holder<br />

Features:<br />

equipment to the work being performed.<br />

Main<br />

7 Tool Bit<br />

Frame Dia.<br />

7<br />

5<br />

• Simultaneously sever and bevel thin or • Excellent for working in tight spaces with<br />

Features:<br />

Cut Line<br />

Notes:<br />

heavy-wall pipe<br />

little clearance<br />

A. Please refer to the • Low friction, field adjustable, bearing system • Adjustable OD mounting system<br />

2<br />

operator's manual<br />

• Numerous drive options<br />

• Cold cutting - No flames or Heat and/or Affected technical • Sever and bevel simultaneously<br />

• Cold cutting Mounting - means Side no heat affected zones<br />

specifications.<br />

Cut line Cl.<br />

• Adjustable OD mounting system featuring<br />

Zones<br />

B. Some listed<br />

• Requires low input horsepower<br />

• Modular design to enhance<br />

specifications may<br />

7<br />

Cut Line Cl.<br />

locator pads & jackscrews for additional • Extendable capabilities with additional refer to specific<br />

• Lightweight, easy to setup<br />

interchangeability Opp. Frame of parts<br />

configurations,<br />

stability<br />

machining accessories<br />

pipe schedules or<br />

material types.<br />

• Worm drive tool modules reduce vibration<br />

• Extended reach tool 6modules for deep severs<br />

and extend tool bit life<br />

Rotation<br />

Measurements indicate the basic machine fitted with standard tool modules.<br />

Optional low axial dimension tool modules are available for the 601SBM<br />

and 602.5SBM. Note: Measurements will vary from those indicated when<br />

machinery is configured for different pipe sizes.<br />

Pipe size range is based on ANSI pipe dimensions. Pipe sizes indicated with (*)<br />

indicate tube sizes, not pipe sizes.<br />

Machine weight is the lifting weight of the machine which includes the basic<br />

machine with standard tool modules.<br />

Rotating parts diameter is the dimension across the face of the machine,<br />

including its moving parts (inner ring and standard tool modules) when the<br />

machine is set-up for the maximum pipe size for the specific model. The<br />

rotating parts diameter becomes less when tool modules are positioned<br />

inward to reach smaller pipes.<br />

Nominal cut line is the dimension from the back of the machine to the center<br />

line of the tool bit slot.<br />

(RBL Model Shown)<br />

1 Drive housing<br />

2 Split Line<br />

3 Locator Pad<br />

4 Tripper Assy.<br />

5 Tool Module<br />

6 Tool Holder<br />

7 Tool Bit<br />

Notes:<br />

A. Pneu. Motor (shown) 3.00"<br />

(76.2mm) up to 612SB, 3.5"<br />

(88.9mm) 616SB and larger.<br />

B. Actual rotating diameter may be<br />

less depending on configuration<br />

and pipe size.<br />

1<br />

3<br />

4<br />

2<br />

B.<br />

6<br />

7<br />

5<br />

A.<br />

WELDING EQUIPMENT<br />

Model Pipe Radial Machine Rotating Parts Machine Machine Base Frame Nominal<br />

Size Range Clearance Weight Diameter OD ID Width Cut Line<br />

Inch (mm) Inch (mm) lbs. (kg) Inch (mm) Inch (mm) I nch (mm) Inch (mm) Inch (mm)<br />

601SBM 1/4 (13.7) - 1 (33.4) 2.00 (50.8) 11.5 (5.2) 5.31 (134.9) 5.31 (134.9) 1.44 (36.6) 2.00 (50.8) 3.50 (88.9)<br />

602TSB *1 1/2 (38.1) - *2 (50.8) 1.49 (37.8) 12.0 (5.4) 4.98 (126.5) 4.98 (126.5) 2.10 (53.3) 2.50 (63.5) 4.00 (101.6)<br />

602.5SBM 1 (33.4) - *3 (76.2) 1.94 (49.3) 14.5 (6.6) 6.87 (174.5) 6.87 (174.5) 3.13 (79.5) 2.00 (50.8) 3.50 (88.9)<br />

604SB 2 (60.3) - 4 (114.3) 2.25 (57.2) 29 (13.1) 9.00 (228.6) 9.00 (228.6) 4.75 (120.7) 3.00 (76.2) 4.50 (114.3)<br />

606SB 3 1/2 (101.6) - 6 (168.3) 2.25 (57.2) 37 (16.8) 11.12 (282.4) 11.12 (282.4) 6.87 (174.5) 3.00 (76.2) 4.50 (114.3)<br />

608SB 5 (141.3) - 8 (219.1) 2.25 (57.2) 43 (19.5) 13.12 (333.2) 13.12 (333.2) 8.95 (227.3) 3.00 (76.2) 4.50 (114.3)<br />

610SB 8 (219.1) - 10 (273.1) 2.50 (63.5) 55 (25.0) 15.75 (400.1) 15.75 (400.1) 11.20 (284.5) 3.00 (76.2) 4.50 (114.3)<br />

612SB 10 (273.1) - 12 (323.9) 2.50 (63.5) 62 (28.1) 17.75 (450.9) 17.75 (450.9) 13.20 (335.3) 3.00 (76.2) 4.50 (114.3)<br />

616SB 12 (323.9) - 16 (406.4) 6.55 (166.4) 200 (91) 29.10 (739.1) 24.00 (609.6) 17.00 (431.8) 4.25 (108.0) 6.93 (176.0)<br />

620SB 16 (406.4) - 20 (508.0) 6.63 (168.4) 320 (145) 33.25 (844.6) 29.20 (741.7) 21.20 (538.5) 4.90 (124.5) 7.58 (192.5)<br />

624SB 20 (508.0) - 24 (609.6) 6.70 (170.2) 350 (159) 37.40 (950.0) 33.40 (848.4) 25.40 (645.2) 4.90 (124.5) 7.58 (192.5)<br />

630SB 26 (660.4) - 30 (762.0) 6.75 (171.5) 420 (191) 43.50 (1104.9) 39.50 (1003.3) 31.50 (800.1) 4.90 (124.5) 7.58 (192.5)<br />

636SB 32 (812.8) - 36 (914.4) 7.05 (179.1) 490 (223) 50.10 (1272.5) 46.00 (1168.4) 38.00 (965.2) 4.90 (124.5) 7.58 (192.5)<br />

642SB 38 (965.2) - 42 (1066.8) 7.10 (180.3) 570 (259) 56.20 (1427.5) 52.00 (1320.8) 44.00 (1117.6) 4.90 (124.5) 7.58 (192.5)<br />

648SB 44 (1117.6) - 48 (1219.2) 7.15 (181.6) 820 (372) 62.30 (1582.4) 58.00 (1473.2) 50.00 (1270.0) 5.75 (146.1) 8.43 (214.1)<br />

614RBL *7 (177.8) - 14 (355.6) 8.09 (205.5) 146 (66) 30.00 (762.0) 21.10 (535.9) 15.00 (381.0) 3.31 (84.1) 6.15 (156.2)<br />

616RBL 10 (273.1) - 16 (406.4) 8.13 (206.5) 159 (72) 32.10 (815.3) 23.10 (586.7) 17.00 (431.8) 3.31 (84.1) 6.15 (156.2)<br />

620RBL 14 (355.6) - 20 (508.0) 8.15 (207.0) 184 (83) 36.20 (919.5) 27.10 (688.3) 21.00 (533.4) 3.31 (84.1) 6.15 (156.2)<br />

624RBL 18 (457.2) - 24 (609.6) 8.31 (211.1) 207 (94) 40.55 (1030.0) 31.10 (789.9) 25.00 (635.0) 3.31 (84.1) 6.15 (156.2)<br />

630RBL 24 (609.6) - 30 (762.0) 8.34 (211.8) 239 (108) 46.65 (1184.9) 37.10 (942.3) 31.00 (787.4) 3.31 (84.1) 6.15 (156.2)<br />

636RBL 30 (762.0) - 36 (914.4) 8.38 (212.9) 264 (120) 52.75 (1339.8) 43.10 (1094.7) 37.00 (939.8) 3.31 (84.1) 6.15 (156.2)<br />

648RBL 42 (1066.8) - 48 (1219.2) 9.00 (228.6) 940 (427) 67.50 (1714.5) 60.00 (1524.0) 50.00 (1270.0) 5.13 (130.3) 7.97 (202.4)<br />

660RBL 54 (1371.6) - 60 (1524.0) 9.00 (228.6) 1120 (508) 79.50 (<strong>2019</strong>.3) 72.00 (1828.8) 62.00 (1574.8) 5.13 (130.3) 7.97 (202.4)<br />

48 <strong>SPW</strong> GROUP PTY LTD