- Page 1 and 2:

URL:http://www.hitachi-c-m.com PRIN

- Page 3:

INDEX EM1NC-EN3-1 MACHINE NUMBERS S

- Page 6 and 7:

BREAK-IN ..........................

- Page 8 and 9:

CONTENTS MEMO .....................

- Page 10 and 11:

Engine TYPE: MFG. NO.: Travel Motor

- Page 12 and 13:

MACHINE NUMBERS MEMO ..............

- Page 14 and 15:

Follow Safety Instructions SAFETY

- Page 16 and 17:

Tidy Up Inside Operator’s Space S

- Page 18 and 19:

Move and Operate Machine Safely SAF

- Page 20 and 21:

Precautions for Operations d WARNIN

- Page 22 and 23:

Equipment of OPG SAFETY • In case

- Page 24 and 25:

SAFETY • Traveling down a slope i

- Page 26 and 27:

Avoid Injury from Back-over and Swi

- Page 28 and 29:

Avoid Tipping SAFETY • The danger

- Page 30 and 31:

Precautions for Lightning SAFETY

- Page 32 and 33:

Safety Transporting SAFETY • The

- Page 34 and 35:

SAFETY • Disconnect battery groun

- Page 36 and 37:

Store Attachments Safely • Stored

- Page 38 and 39:

Prevent Fires SAFETY Check for Oil

- Page 40 and 41:

Beware of Exhaust Fumes SAFETY •

- Page 42 and 43:

Remove Paint Before Welding or Heat

- Page 44 and 45:

SAFETY MEMO .......................

- Page 46 and 47:

SAFETY SIGNS SS4420333 • If the p

- Page 48 and 49:

• Sign indicates the hazard of ro

- Page 50 and 51:

• Hot coolant or oil may spout if

- Page 52 and 53:

ROPS/TOPS/TOP GUARD Canopy and Cab

- Page 54 and 55:

SAFETY SIGNS MEMO .................

- Page 56 and 57:

ZX27-3 1- Counterweight 2- Cab 3- B

- Page 58 and 59:

Switch Panel 5- Work Light Switch P

- Page 60 and 61:

Monitor Panel 1- Alternator Indicat

- Page 62 and 63:

OPERATOR'S STATION Cab Heater Opera

- Page 64 and 65:

OPERATOR'S STATION AM/FM Radio Oper

- Page 66 and 67:

Station Presetting Procedure 1. Sel

- Page 68 and 69:

Opening/Closing Cab Front Window (Z

- Page 70 and 71:

Emergency Exit (ZX27-3) If the oper

- Page 72 and 73:

Tool and Operator’s Manual Box

- Page 74 and 75:

Cab Light (Cab Equipped Machines) M

- Page 76 and 77:

OPERATOR'S STATION MEMO ...........

- Page 78 and 79:

BREAK-IN MEMO .....................

- Page 80 and 81:

Starting Engine Starting in Ordinar

- Page 82 and 83:

ZX27-3 1. Check that pilot control

- Page 84 and 85:

Using Booster Battery d OPERATING E

- Page 86 and 87:

OPERATING ENGINE MEMO .............

- Page 88 and 89:

d • Pivot Turn Steer the machine

- Page 90 and 91:

Traveling on Soft Ground DRIVING MA

- Page 92 and 93:

Driving in Water or on Soft Ground

- Page 94 and 95:

DRIVING MACHINE MEMO ..............

- Page 96 and 97:

Boom-Swing Pedal Use the boom swing

- Page 98 and 99:

Blade Lever OPERATING MACHINE Use b

- Page 100 and 101:

Blade and Track Width Control Lever

- Page 102 and 103:

Pilot Control Shut-Off Lever The pi

- Page 104 and 105:

Warming Up Operation OPERATING MACH

- Page 106 and 107:

Grading Operation OPERATING MACHINE

- Page 108 and 109:

OPERATING MACHINE Avoid Other Than

- Page 110 and 111:

Avoid Hitting Blade with Bucket Whe

- Page 112 and 113:

3. Operating the machine with rubbe

- Page 114 and 115:

Precautions for Breaker Operation O

- Page 116 and 117:

Average Breaker Operating Availabil

- Page 118 and 119:

OPERATING MACHINE • When crushing

- Page 120 and 121:

d d 3. Lower the boom in the follow

- Page 122 and 123:

Loading d WARNING: • Always trave

- Page 124 and 125:

Unloading d WARNING: • Always tra

- Page 126 and 127:

TRANSPORTING MEMO .................

- Page 128 and 129:

Prepare Machine for Inspection/Main

- Page 130 and 131:

Opening/Closing Tank Covers (ZX27-3

- Page 132 and 133:

Daily Inspection Engine Upperstruct

- Page 134 and 135:

Periodic Replacement of Parts MAINT

- Page 136 and 137:

MAINTENANCE E. Fuel System (See Pag

- Page 138 and 139:

Brand Names of Recommended Oil and

- Page 140 and 141:

Gear Oil Air Temp Gear Oil -20 to 4

- Page 142 and 143:

2.3 Boom foot 2.4 Arm cylinder rod

- Page 144 and 145:

2 3 Bucket and Link Pins --- every

- Page 146 and 147: 5 d Swing Internal Gear --- every 5

- Page 148 and 149: 1 2 d Change Engine Oil / Replace E

- Page 150 and 151: C. Transmission 1 Travel Reduction

- Page 152 and 153: ZX27-3 1. Park the machine on a lev

- Page 154 and 155: 1 MAINTENANCE 3. Begin servicing hy

- Page 156 and 157: 3 d Change Hydraulic Oil --- every

- Page 158 and 159: Bleed Air from Hydraulic System Aft

- Page 160 and 161: 5 d Replace Full Flow Filter --- ev

- Page 162 and 163: MAINTENANCE 4. Rotate the hexagon s

- Page 164 and 165: Hoses MAINTENANCE Interval (Hours)

- Page 166 and 167: Hose Fitting • Metal Face Seal Fi

- Page 168 and 169: d 1. Connecting Coupler MAINTENANCE

- Page 170 and 171: E. Fuel System d MAINTENANCE WARNIN

- Page 172 and 173: 2 Drain Fuel Tank Sump --- as requi

- Page 174 and 175: 4 Check Fuel Hoses --- daily MAINTE

- Page 176 and 177: d d ZX27-3 MAINTENANCE 1. Before se

- Page 178 and 179: Precautions for Handling LLC d WARN

- Page 180 and 181: Adjustment of Fan Belt Tension ZX14

- Page 182 and 183: 3 Change Coolant --- twice a year (

- Page 184 and 185: 4 d Clean Radiator --- every 500 ho

- Page 186 and 187: Electrolyte Level Check MAINTENANCE

- Page 188 and 189: d Precautions for Handling Battery

- Page 190 and 191: I. Miscellaneous 1 Check Bucket Tee

- Page 192 and 193: 2 d Replace Bucket MAINTENANCE WARN

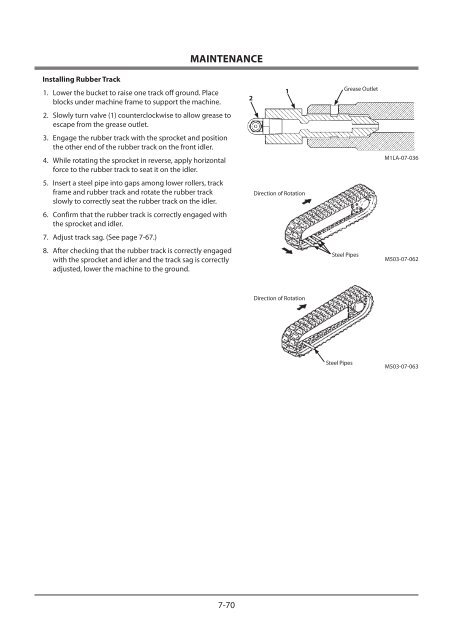

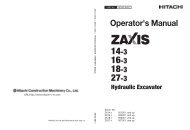

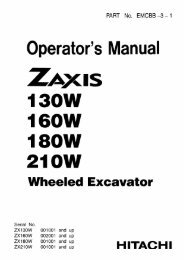

- Page 194 and 195: d Loosen Track (Rubber Crawler) WAR

- Page 198 and 199: d Loosen Track (Steel Crawler) CAUT

- Page 200 and 201: 5 Check and Replace Seat Belt Check

- Page 202 and 203: 7 Check Injection Nozzle Cleaning -

- Page 204 and 205: ZX27-3 MAINTENANCE No. Descriptions

- Page 206 and 207: MAINTENANCE MEMO ..................

- Page 208 and 209: CONSUMABLE PARTS LIST MEMO ........

- Page 210 and 211: MAINTENANCE UNDER SPECIAL ENVIRONME

- Page 212 and 213: Removing Machine from Storage d STO

- Page 214 and 215: Engine TROUBLESHOOTING Problem Caus

- Page 216 and 217: Engine TROUBLESHOOTING Problem Caus

- Page 218 and 219: Electrical System TROUBLESHOOTING P

- Page 220 and 221: Hydraulic System TROUBLESHOOTING Pr

- Page 222 and 223: Hydraulic System TROUBLESHOOTING Pr

- Page 225 and 226: Bucket Types and Applications ZX14-

- Page 228 and 229: Bucket Types and Applications ZX16-

- Page 231 and 232: Bucket Types and Applications ZX18-

- Page 234 and 235: Bucket Types and Applications ZX27-

- Page 236 and 237: Special Specification d SPECIFICATI

- Page 238 and 239: Basic Functions This system enables

- Page 240 and 241: Unlocking OPTIONAL ATTACHMENT AND D

- Page 242 and 243: Changing Delayed Locking Timer Sett

- Page 244 and 245: OPTIONAL ATTACHMENT AND DEVICE MEMO

- Page 246 and 247:

Engine Oil Pressure Indicator .....

- Page 248 and 249:

INDEX MEMO ........................

- Page 251:

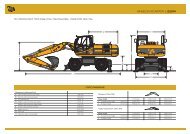

Hydraulic Excavator ZX14-3/ZX16-3/Z