WARNING - Flannery Plant Hire

WARNING - Flannery Plant Hire

WARNING - Flannery Plant Hire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

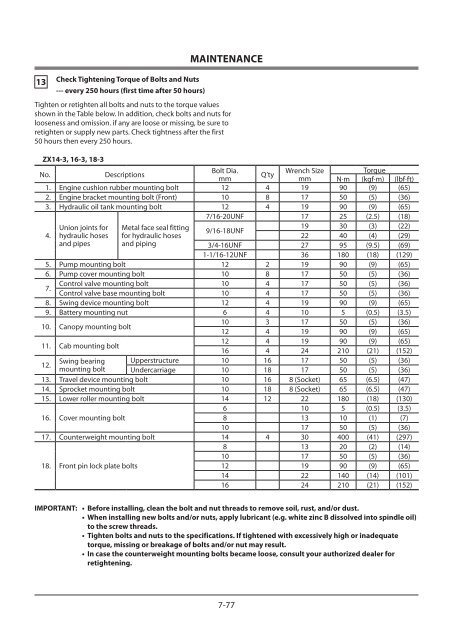

13<br />

Check Tightening Torque of Bolts and Nuts<br />

--- every 250 hours (first time after 50 hours)<br />

MAINTENANCE<br />

Tighten or retighten all bolts and nuts to the torque values<br />

shown in the Table below. In addition, check bolts and nuts for<br />

looseness and omission. if any are loose or missing, be sure to<br />

retighten or supply new parts. Check tightness after the first<br />

50 hours then every 250 hours.<br />

ZX14-3, 16-3, 18-3<br />

No. Descriptions<br />

Bolt Dia.<br />

mm<br />

Q’ty<br />

Wrench Size<br />

mm N⋅m<br />

Torque<br />

(kgf⋅m) (lbf⋅ft)<br />

1. Engine cushion rubber mounting bolt 12 4 19 90 (9) (65)<br />

2. Engine bracket mounting bolt (Front) 10 8 17 50 (5) (36)<br />

3. Hydraulic oil tank mounting bolt 12 4 19 90 (9) (65)<br />

7/16-20UNF 17 25 (2.5) (18)<br />

4.<br />

Union joints for<br />

hydraulic hoses<br />

Metal face seal fitting<br />

for hydraulic hoses<br />

9/16-18UNF<br />

19<br />

22<br />

30<br />

40<br />

(3)<br />

(4)<br />

(22)<br />

(29)<br />

and pipes and piping<br />

3/4-16UNF 27 95 (9.5) (69)<br />

1-1/16-12UNF 36 180 (18) (129)<br />

5. Pump mounting bolt 12 2 19 90 (9) (65)<br />

6. Pump cover mounting bolt 10 8 17 50 (5) (36)<br />

7.<br />

Control valve mounting bolt<br />

Control valve base mounting bolt<br />

10<br />

10<br />

4<br />

4<br />

17<br />

17<br />

50<br />

50<br />

(5)<br />

(5)<br />

(36)<br />

(36)<br />

8. Swing device mounting bolt 12 4 19 90 (9) (65)<br />

9. Battery mounting nut 6 4 10 5 (0.5) (3.5)<br />

10. Canopy mounting bolt<br />

10<br />

12<br />

3<br />

4<br />

17<br />

19<br />

50<br />

90<br />

(5)<br />

(9)<br />

(36)<br />

(65)<br />

11. Cab mounting bolt<br />

12<br />

16<br />

4<br />

4<br />

19<br />

24<br />

90<br />

210<br />

(9)<br />

(21)<br />

(65)<br />

(152)<br />

12.<br />

Swing bearing<br />

mounting bolt<br />

Upperstructure<br />

Undercarriage<br />

10<br />

10<br />

16<br />

18<br />

17<br />

17<br />

50<br />

50<br />

(5)<br />

(5)<br />

(36)<br />

(36)<br />

13. Travel device mounting bolt 10 16 8 (Socket) 65 (6.5) (47)<br />

14. Sprocket mounting bolt 10 18 8 (Socket) 65 (6.5) (47)<br />

15. Lower roller mounting bolt 14 12 22 180 (18) (130)<br />

6 10 5 (0.5) (3.5)<br />

16. Cover mounting bolt<br />

8 13 10 (1) (7)<br />

10 17 50 (5) (36)<br />

17. Counterweight mounting bolt 14 4 30 400 (41) (297)<br />

8 13 20 (2) (14)<br />

10 17 50 (5) (36)<br />

18. Front pin lock plate bolts<br />

12 19 90 (9) (65)<br />

14 22 140 (14) (101)<br />

16 24 210 (21) (152)<br />

IMPORTANT: • Before installing, clean the bolt and nut threads to remove soil, rust, and/or dust.<br />

• When installing new bolts and/or nuts, apply lubricant (e.g. white zinc B dissolved into spindle oil)<br />

to the screw threads.<br />

• Tighten bolts and nuts to the specifications. If tightened with excessively high or inadequate<br />

torque, missing or breakage of bolts and/or nut may result.<br />

• In case the counterweight mounting bolts became loose, consult your authorized dealer for<br />

retightening.<br />

7-77