WARNING - Flannery Plant Hire

WARNING - Flannery Plant Hire

WARNING - Flannery Plant Hire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

d<br />

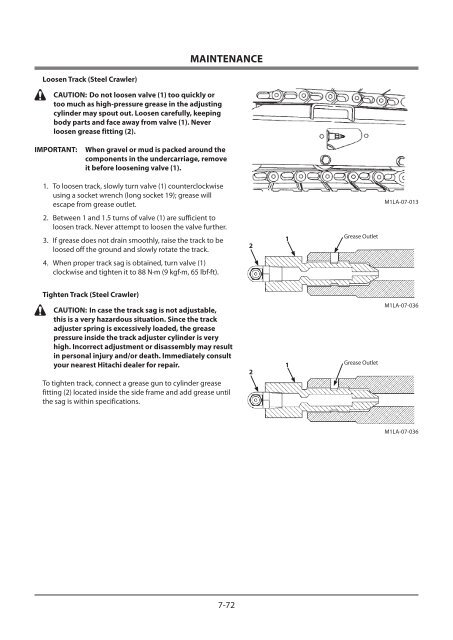

Loosen Track (Steel Crawler)<br />

CAUTION: Do not loosen valve (1) too quickly or<br />

too much as high-pressure grease in the adjusting<br />

cylinder may spout out. Loosen carefully, keeping<br />

body parts and face away from valve (1). Never<br />

loosen grease fitting (2).<br />

MAINTENANCE<br />

IMPORTANT: When gravel or mud is packed around the<br />

components in the undercarriage, remove<br />

it before loosening valve (1).<br />

d<br />

1. To loosen track, slowly turn valve (1) counterclockwise<br />

using a socket wrench (long socket 19); grease will<br />

escape from grease outlet.<br />

2. Between 1 and 1.5 turns of valve (1) are sufficient to<br />

loosen track. Never attempt to loosen the valve further.<br />

3. If grease does not drain smoothly, raise the track to be<br />

loosed off the ground and slowly rotate the track.<br />

4. When proper track sag is obtained, turn valve (1)<br />

clockwise and tighten it to 88 N·m (9 kgf·m, 65 lbf·ft).<br />

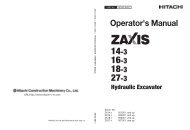

Tighten Track (Steel Crawler)<br />

CAUTION: In case the track sag is not adjustable,<br />

this is a very hazardous situation. Since the track<br />

adjuster spring is excessively loaded, the grease<br />

pressure inside the track adjuster cylinder is very<br />

high. Incorrect adjustment or disassembly may result<br />

in personal injury and/or death. Immediately consult<br />

your nearest Hitachi dealer for repair.<br />

To tighten track, connect a grease gun to cylinder grease<br />

fitting (2) located inside the side frame and add grease until<br />

the sag is within specifications.<br />

7-72<br />

2<br />

2<br />

1<br />

1<br />

Grease Outlet<br />

Grease Outlet<br />

M1LA-07-013<br />

M1LA-07-036<br />

M1LA-07-036