PuK - Process Technology & Components 2024

A technical trade magazine with a history of more than 60 years.

A technical trade magazine with a history of more than 60 years.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Leading article<br />

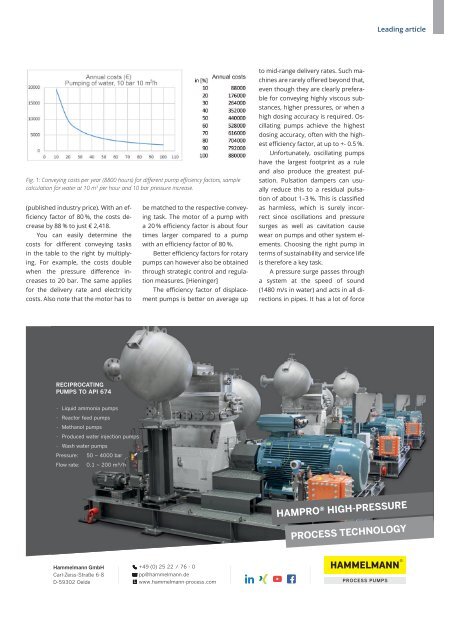

Fig. 1: Conveying costs per year (8800 hours) for different pump efficiency factors, sample<br />

calculation for water at 10 m 3 per hour and 10 bar pressure increase.<br />

(published industry price). With an efficiency<br />

factor of 80 %, the costs decrease<br />

by 88 % to just € 2,418.<br />

You can easily determine the<br />

costs for different conveying tasks<br />

in the table to the right by multiplying.<br />

For example, the costs double<br />

when the pressure difference increases<br />

to 20 bar. The same applies<br />

for the delivery rate and electricity<br />

costs. Also note that the motor has to<br />

be matched to the respective conveying<br />

task. The motor of a pump with<br />

a 20 % efficiency factor is about four<br />

times larger compared to a pump<br />

with an efficiency factor of 80 %.<br />

Better efficiency factors for rotary<br />

pumps can however also be obtained<br />

through strategic control and regulation<br />

measures. [Hieninger]<br />

The efficiency factor of displacement<br />

pumps is better on average up<br />

to mid-range delivery rates. Such machines<br />

are rarely offered beyond that,<br />

even though they are clearly preferable<br />

for conveying highly viscous substances,<br />

higher pressures, or when a<br />

high dosing accuracy is required. Oscillating<br />

pumps achieve the highest<br />

dosing accuracy, often with the highest<br />

efficiency factor, at up to +- 0.5 %.<br />

Unfortunately, oscillating pumps<br />

have the largest footprint as a rule<br />

and also produce the greatest pulsation.<br />

Pulsation dampers can usually<br />

reduce this to a residual pulsation<br />

of about 1–3 %. This is classified<br />

as harmless, which is surely incorrect<br />

since oscillations and pressure<br />

surges as well as cavitation cause<br />

wear on pumps and other system elements.<br />

Choosing the right pump in<br />

terms of sustainability and service life<br />

is therefore a key task.<br />

A pressure surge passes through<br />

a system at the speed of sound<br />

(1480 m/s in water) and acts in all directions<br />

in pipes. It has a lot of force<br />

RECIPROCATING<br />

PUMPS TO API 674<br />

- Liquid ammonia pumps<br />

- Reactor feed pumps<br />

- Methanol pumps<br />

- Produced water injection pumps<br />

- Wash water pumps<br />

Pressure:<br />

Flow rate:<br />

50 – 4000 bar<br />

0,1 – 200 m³/h<br />

HAMPRO® HIGH-PRESSURE<br />

PROCESS TECHNOLOGY<br />

Hammelmann GmbH<br />

Carl-Zeiss-Straße 6-8<br />

D-59302 Oelde<br />

+49 (0) 25 22 / 76 - 0<br />

pp@hammelmann.de<br />

www.hammelmann-process.com