PuK - Process Technology & Components 2024

A technical trade magazine with a history of more than 60 years.

A technical trade magazine with a history of more than 60 years.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Components</strong><br />

Plant documentation<br />

When envisaging Plant Documentation<br />

4.0 probably the first aspect to<br />

be considered is the advantages for<br />

maintenance. Here, of course, it is extremely<br />

useful to know the current<br />

state of the plant and be able to easily<br />

document the changes. To do this,<br />

maintenance crews can simply enter<br />

the change on a tablet with a stylus<br />

(Fig. 3), and it is saved together with<br />

the information about who made the<br />

change, when, and explanation if necessary.<br />

Workflows built into the system<br />

then ensure that the original<br />

documentation is reviewed regularly<br />

and thus stays clear and up-to-date.<br />

In addition to maintenance, many<br />

other areas benefit from digital documentation<br />

(Fig. 4). These include<br />

e. g., troubleshooting, large-scale revisions,<br />

project-related documentation,<br />

loop checks and the management<br />

of assets, the integration of<br />

package units, and know-how transfer.<br />

And when it comes to audits, it<br />

certainly pays off to have up-to-date,<br />

legally compliant documentation at<br />

hand at all times.<br />

Fig. 2: LiveDOK makes distributed documentation of large-scale plants digitally available<br />

to engineers and plant operators: all relevant documents and drawings are presented in a<br />

structured way on one unified, intuitive user interface – regardless of their format and medium.<br />

Plant data can be administered, searched and corrected in real time – from planning<br />

to operation, anytime, anywhere. (Copyright: Rösberg)<br />

Troubleshooting, large-scale<br />

revisions and loop checks<br />

When something goes wrong, every<br />

minute counts. In a situation of<br />

Various use cases benefit from<br />

Plant Documentation 4.0<br />

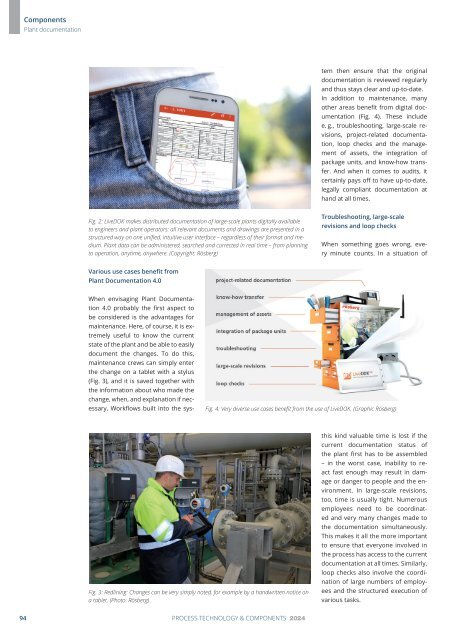

Fig. 4: Very diverse use cases benefit from the use of LiveDOK. (Graphic Rösberg)<br />

Fig. 3: Redlining: Changes can be very simply noted, for example by a handwritten notice on<br />

a tablet. (Photo: Rösberg)<br />

this kind valuable time is lost if the<br />

current documentation status of<br />

the plant first has to be assembled<br />

– in the worst case, inability to react<br />

fast enough may result in damage<br />

or danger to people and the environment.<br />

In large-scale revisions,<br />

too, time is usually tight. Numerous<br />

employees need to be coordinated<br />

and very many changes made to<br />

the documentation simultaneously.<br />

This makes it all the more important<br />

to ensure that everyone involved in<br />

the process has access to the current<br />

documentation at all times. Similarly,<br />

loop checks also involve the coordination<br />

of large numbers of employees<br />

and the structured execution of<br />

various tasks.<br />

94 PROCESS TECHNOLOGY & COMPONENTS <strong>2024</strong>