PuK - Process Technology & Components 2024

A technical trade magazine with a history of more than 60 years.

A technical trade magazine with a history of more than 60 years.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Compressors and Systems<br />

Machine room ventilation<br />

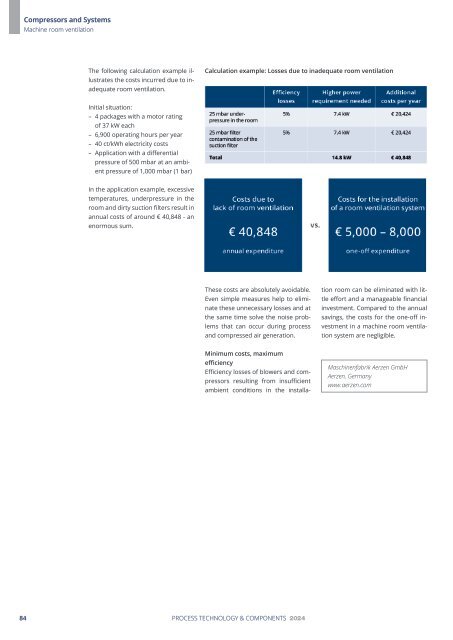

The following calculation example illustrates<br />

the costs incurred due to inadequate<br />

room ventilation.<br />

Calculation example: Losses due to inadequate room ventilation<br />

Initial situation:<br />

– 4 packages with a motor rating<br />

of 37 kW each<br />

– 6,900 operating hours per year<br />

– 40 ct/kWh electricity costs<br />

– Application with a differential<br />

pressure of 500 mbar at an ambient<br />

pressure of 1,000 mbar (1 bar)<br />

In the application example, excessive<br />

temperatures, underpressure in the<br />

room and dirty suction filters result in<br />

annual costs of around € 40,848 - an<br />

enormous sum.<br />

These costs are absolutely avoidable.<br />

Even simple measures help to eliminate<br />

these unnecessary losses and at<br />

the same time solve the noise problems<br />

that can occur during process<br />

and compressed air generation.<br />

tion room can be eliminated with little<br />

effort and a manageable financial<br />

investment. Compared to the annual<br />

savings, the costs for the one-off investment<br />

in a machine room ventilation<br />

system are negligible.<br />

Minimum costs, maximum<br />

efficiency<br />

Efficiency losses of blowers and compressors<br />

resulting from insufficient<br />

ambient conditions in the installa-<br />

Maschinenfabrik Aerzen GmbH<br />

Aerzen, Germany<br />

www.aerzen.com<br />

84 PROCESS TECHNOLOGY & COMPONENTS <strong>2024</strong>