PuK - Process Technology & Components 2024

A technical trade magazine with a history of more than 60 years.

A technical trade magazine with a history of more than 60 years.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Pumps and Systems<br />

Diaphragm metering pumps<br />

motor or permanent magnet synchronous<br />

motor (PMSM) is variable<br />

and operating points can be approached<br />

precisely and reproducibly<br />

without manual stroke adjustment<br />

– thus making them compliant with<br />

GMP. At ±1 percent, metering accuracy<br />

is extremely accurate. To prepare<br />

the mixtures in the chromatographic<br />

environment, the flow rates<br />

of the individual pump lines must be<br />

precisely maintained. For this purpose,<br />

they are determined by Coriolis<br />

flow meters and precisely controlled<br />

at the specified target values using<br />

the speed control of the pumps. Additional<br />

online monitoring of the pH<br />

value and electrical conductivity ensures<br />

continuous control of the process<br />

conditions.<br />

To ensure that the specified accuracies<br />

are maintained over wide adjustment<br />

ranges, correct suction-side<br />

pressures (NPIPA) must be ensured<br />

at the pumps. The abbreviation NPIP<br />

stands for “Net Positive Inlet Pressure”<br />

and NPIPA for “Net Positive Inlet<br />

Pressure Available”. The NPIP is similar<br />

to the well-known NPSH, although<br />

the latter is only defined by the<br />

height. In contrast, the NPIPA is the<br />

measure of the pump inlet pressure<br />

present at the inlet valves through<br />

the system. The NPIP is determined<br />

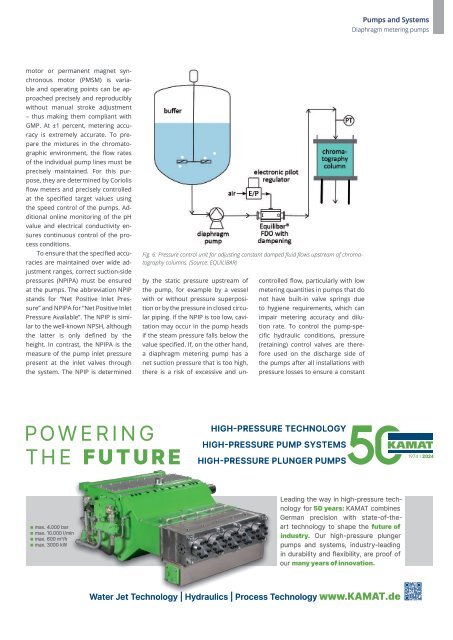

Fig. 6: Pressure control unit for adjusting constant damped fluid flows upstream of chromatography<br />

columns. (Source: EQUILIBAR)<br />

by the static pressure upstream of<br />

the pump, for example by a vessel<br />

with or without pressure superposition<br />

or by the pressure in closed circular<br />

piping. If the NPIP is too low, cavitation<br />

may occur in the pump heads<br />

if the steam pressure falls below the<br />

value specified. If, on the other hand,<br />

a diaphragm metering pump has a<br />

net suction pressure that is too high,<br />

there is a risk of excessive and uncontrolled<br />

flow, particularly with low<br />

metering quantities in pumps that do<br />

not have built-in valve springs due<br />

to hygiene requirements, which can<br />

impair metering accuracy and dilution<br />

rate. To control the pump-specific<br />

hydraulic conditions, pressure<br />

(retaining) control valves are therefore<br />

used on the discharge side of<br />

the pumps after all installations with<br />

pressure losses to ensure a constant<br />

max. 4.000 bar<br />

max. 10.000 l/min<br />

max. 600 m 3 /h<br />

max. 3000 kW