PuK - Process Technology & Components 2024

A technical trade magazine with a history of more than 60 years.

A technical trade magazine with a history of more than 60 years.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Compressors/Compressed air/<strong>Components</strong><br />

Companies – Innovations – Products<br />

The pressure downstream of the Iris ® <strong>Process</strong> Control Valves can be<br />

read from the graphs of this SCADA print out shown in Fig. 3. This information<br />

is helpful to identify any need for maintenance of the diffusors.<br />

The Iris ® valves have been working for over 10 years to full satisfaction.<br />

Fig. 1: Egger Iris ® diaphragm control valve for precise air control at the biology of<br />

the Stendal wastewater treatment plant<br />

Besides the significant energy savings due to the lowered DO set point,<br />

the oxygen transfer could be improved. In addition, the diffusers can<br />

be flushed more effectively because of to the higher flow capacity of<br />

the Egger Iris ® valves compared to the former butterfly valves.<br />

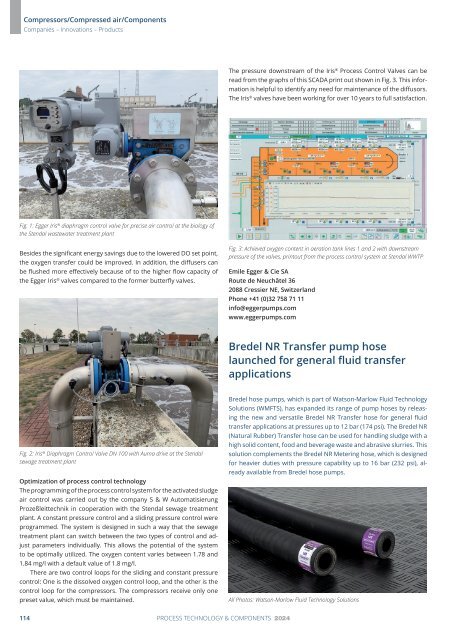

Fig. 3: Achieved oxygen content in aeration tank lines 1 and 2 with downstream<br />

pressure of the valves, printout from the process control system at Stendal WWTP<br />

Emile Egger & Cie SA<br />

Route de Neuchâtel 36<br />

2088 Cressier NE, Switzerland<br />

Phone +41 (0)32 758 71 11<br />

info@eggerpumps.com<br />

www.eggerpumps.com<br />

Bredel NR Transfer pump hose<br />

launched for general fluid transfer<br />

applications<br />

Fig. 2: Iris ® Diaphragm Control Valve DN 100 with Auma drive at the Stendal<br />

sewage treatment plant<br />

Optimization of process control technology<br />

The programming of the process control system for the activated sludge<br />

air control was carried out by the company S & W Automatisierung<br />

Prozeßleittechnik in cooperation with the Stendal sewage treatment<br />

plant. A constant pressure control and a sliding pressure control were<br />

programmed. The system is designed in such a way that the sewage<br />

treatment plant can switch between the two types of control and adjust<br />

parameters individually. This allows the potential of the system<br />

to be optimally utilized. The oxygen content varies between 1.78 and<br />

1.84 mg/l with a default value of 1.8 mg/l.<br />

There are two control loops for the sliding and constant pressure<br />

control: One is the dissolved oxygen control loop, and the other is the<br />

control loop for the compressors. The compressors receive only one<br />

preset value, which must be maintained.<br />

Bredel hose pumps, which is part of Watson-Marlow Fluid <strong>Technology</strong><br />

Solutions (WMFTS), has expanded its range of pump hoses by releasing<br />

the new and versatile Bredel NR Transfer hose for general fluid<br />

transfer applications at pressures up to 12 bar (174 psi). The Bredel NR<br />

(Natural Rubber) Transfer hose can be used for handling sludge with a<br />

high solid content, food and beverage waste and abrasive slurries. This<br />

solution complements the Bredel NR Metering hose, which is designed<br />

for heavier duties with pressure capability up to 16 bar (232 psi), already<br />

available from Bredel hose pumps.<br />

All Photos: Watson-Marlow Fluid <strong>Technology</strong> Solutions<br />

114 PROCESS TECHNOLOGY & COMPONENTS <strong>2024</strong>