PuK - Process Technology & Components 2024

A technical trade magazine with a history of more than 60 years.

A technical trade magazine with a history of more than 60 years.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cover story<br />

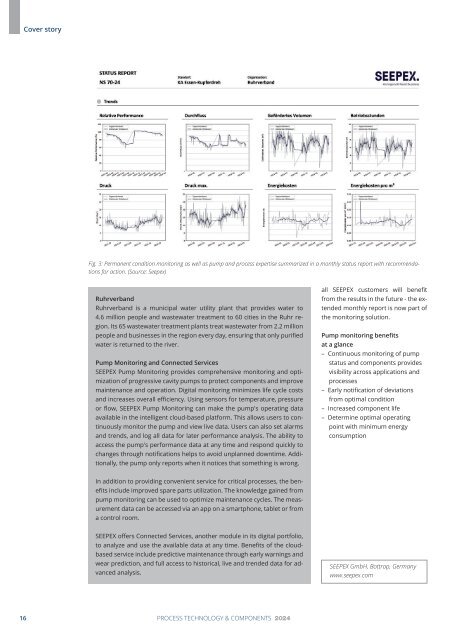

Fig. 3: Permanent condition monitoring as well as pump and process expertise summarized in a monthly status report with recommendations<br />

for action. (Source: Seepex)<br />

Ruhrverband<br />

Ruhrverband is a municipal water utility plant that provides water to<br />

4.6 million people and wastewater treatment to 60 cities in the Ruhr region.<br />

Its 65 wastewater treatment plants treat wastewater from 2.2 million<br />

people and businesses in the region every day, ensuring that only purified<br />

water is returned to the river.<br />

Pump Monitoring and Connected Services<br />

SEEPEX Pump Monitoring provides comprehensive monitoring and optimization<br />

of progressive cavity pumps to protect components and improve<br />

maintenance and operation. Digital monitoring minimizes life cycle costs<br />

and increases overall efficiency. Using sensors for temperature, pressure<br />

or flow, SEEPEX Pump Monitoring can make the pump's operating data<br />

available in the intelligent cloud-based platform. This allows users to continuously<br />

monitor the pump and view live data. Users can also set alarms<br />

and trends, and log all data for later performance analysis. The ability to<br />

access the pump's performance data at any time and respond quickly to<br />

changes through notifications helps to avoid unplanned downtime. Additionally,<br />

the pump only reports when it notices that something is wrong.<br />

all SEEPEX customers will benefit<br />

from the results in the future - the extended<br />

monthly report is now part of<br />

the monitoring solution.<br />

Pump monitoring benefits<br />

at a glance<br />

– Continuous monitoring of pump<br />

status and components provides<br />

visibility across applications and<br />

processes<br />

– Early notification of deviations<br />

from optimal condition<br />

– Increased component life<br />

– Determine optimal operating<br />

point with minimum energy<br />

consumption<br />

In addition to providing convenient service for critical processes, the benefits<br />

include improved spare parts utilization. The knowledge gained from<br />

pump monitoring can be used to optimize maintenance cycles. The measurement<br />

data can be accessed via an app on a smartphone, tablet or from<br />

a control room.<br />

SEEPEX offers Connected Services, another module in its digital portfolio,<br />

to analyze and use the available data at any time. Benefits of the cloudbased<br />

service include predictive maintenance through early warnings and<br />

wear prediction, and full access to historical, live and trended data for advanced<br />

analysis.<br />

SEEPEX GmbH, Bottrop, Germany<br />

www.seepex.com<br />

16 PROCESS TECHNOLOGY & COMPONENTS <strong>2024</strong>