2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HOOK-UP DIAGRAMS<br />

120<br />

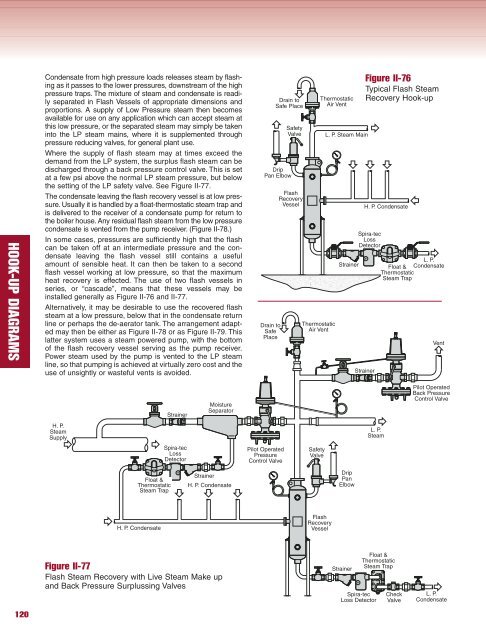

Condensate from high pressure loads releases steam by flashing<br />

as it passes to the lower pressures, downstream of the high<br />

pressure traps. The mixture of steam and condensate is readily<br />

separated in Flash Vessels of appropriate dimensions and<br />

proportions. A s<strong>up</strong>ply of Low Pressure steam then becomes<br />

available for use on any application which can accept steam at<br />

this low pressure, or the separated steam may simply be taken<br />

into the LP steam mains, where it is s<strong>up</strong>plemented through<br />

pressure reducing valves, for general plant use.<br />

Where the s<strong>up</strong>ply of flash steam may at times exceed the<br />

demand from the LP system, the surplus flash steam can be<br />

discharged through a back pressure control valve. This is set<br />

at a few psi above the normal LP steam pressure, but below<br />

the setting of the LP safety valve. See Figure II-77.<br />

The condensate leaving the flash recovery vessel is at low pressure.<br />

Usually it is handled by a float-thermostatic steam trap and<br />

is delivered to the receiver of a condensate pump for return to<br />

the boiler house. Any residual flash steam from the low pressure<br />

condensate is vented from the pump receiver. (Figure II-78.)<br />

In some cases, pressures are sufficiently high that the flash<br />

can be taken off at an intermediate pressure and the condensate<br />

leaving the flash vessel still contains a useful<br />

amount of sensible heat. It can then be taken to a second<br />

flash vessel working at low pressure, so that the maximum<br />

heat recovery is effected. The use of two flash vessels in<br />

series, or “cascade”, means that these vessels may be<br />

installed generally as Figure II-76 and II-77.<br />

Alternatively, it may be desirable to use the recovered flash<br />

steam at a low pressure, below that in the condensate return<br />

line or perhaps the de-aerator tank. The arrangement adapted<br />

may then be either as Figure II-78 or as Figure II-79. This<br />

latter system uses a steam powered pump, with the bottom<br />

of the flash recovery vessel serving as the pump receiver.<br />

Power steam used by the pump is vented to the LP steam<br />

line, so that pumping is achieved at virtually zero cost and the<br />

use of unsightly or wasteful vents is avoided.<br />

H. P.<br />

Steam<br />

S<strong>up</strong>ply<br />

Float &<br />

Thermostatic<br />

Steam Trap<br />

H. P. Condensate<br />

Strainer<br />

Spira-tec<br />

Loss<br />

Detector<br />

Moisture<br />

Separator<br />

Strainer<br />

H. P. Condensate<br />

Figure II-77<br />

Flash Steam Recovery with Live Steam Make <strong>up</strong><br />

and Back Pressure Surplussing Valves<br />

Drip<br />

Pan Elbow<br />

Drain to<br />

Safe<br />

Place<br />

Pilot Operated<br />

Pressure<br />

Control Valve<br />

Drain to<br />

Safe Place<br />

Safety<br />

Valve<br />

Flash<br />

Recovery<br />

Vessel<br />

Thermostatic<br />

Air Vent<br />

Safety<br />

Valve<br />

Flash<br />

Recovery<br />

Vessel<br />

Thermostatic<br />

Air Vent<br />

L. P. Steam Main<br />

Figure II-76<br />

Typical Flash Steam<br />

Recovery <strong>Hook</strong>-<strong>up</strong><br />

Spira-tec<br />

Loss<br />

Detector<br />

L. P.<br />

Strainer Float & Condensate<br />

Thermostatic<br />

Steam Trap<br />

Drip<br />

Pan<br />

Elbow<br />

Strainer<br />

Strainer<br />

L. P.<br />

Steam<br />

Spira-tec<br />

Loss Detector<br />

H. P. Condensate<br />

Float &<br />

Thermostatic<br />

Steam Trap<br />

Check<br />

Valve<br />

Vent<br />

Pilot Operated<br />

Back Pressure<br />

Control Valve<br />

L. P.<br />

Condensate