2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

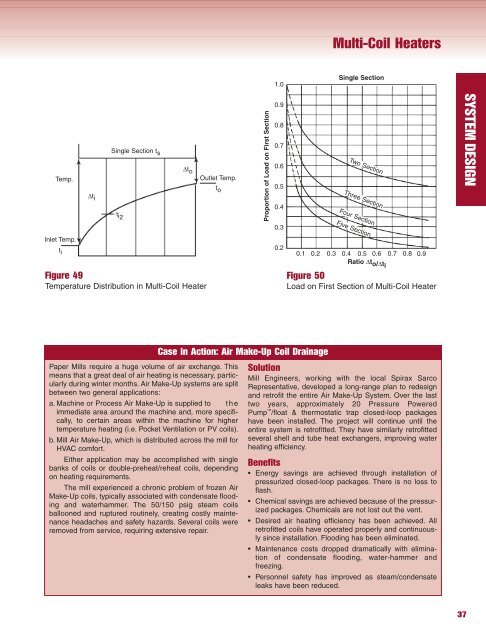

Temp.<br />

Inlet Temp.<br />

t i<br />

∆t i<br />

Single Section t s<br />

t i2<br />

∆t o<br />

Figure 49<br />

Temperature Distribution in Multi-Coil Heater<br />

Outlet Temp.<br />

Paper Mills require a huge volume of air exchange. This<br />

means that a great deal of air heating is necessary, particularly<br />

during winter months. Air Make-Up systems are split<br />

between two general applications:<br />

a. Machine or Process Air Make-Up is s<strong>up</strong>plied to t h e<br />

immediate area around the machine and, more specifically,<br />

to certain areas within the machine for higher<br />

temperature heating (i.e. Pocket Ventilation or PV coils).<br />

b. Mill Air Make-Up, which is distributed across the mill for<br />

HVAC comfort.<br />

Either application may be accomplished with single<br />

banks of coils or double-preheat/reheat coils, depending<br />

on heating requirements.<br />

The mill experienced a chronic problem of frozen Air<br />

Make-Up coils, typically associated with condensate flooding<br />

and waterhammer. The 50/150 psig steam coils<br />

ballooned and r<strong>up</strong>tured routinely, creating costly maintenance<br />

headaches and safety hazards. Several coils were<br />

removed from service, requiring extensive repair.<br />

t o<br />

Proportion of Load on First Section<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

Case in Action: Air Make-Up Coil Drainage<br />

Multi-Coil Heaters<br />

Single Section<br />

Two Section<br />

Three Section<br />

Four Section<br />

Five Section<br />

0.2<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9<br />

Ratio ∆to/∆ti Figure 50<br />

Load on First Section of Multi-Coil Heater<br />

Solution<br />

Mill Engineers, working with the local <strong>Spirax</strong> <strong>Sarco</strong><br />

Representative, developed a long-range plan to redesign<br />

and retrofit the entire Air Make-Up System. Over the last<br />

two years, approximately 20 Pressure Powered<br />

Pump /float & thermostatic trap closed-loop packages<br />

have been installed. The project will continue until the<br />

entire system is retrofitted. They have similarly retrofitted<br />

several shell and tube heat exchangers, improving water<br />

heating efficiency.<br />

Benefits<br />

• Energy savings are achieved through installation of<br />

pressurized closed-loop packages. There is no loss to<br />

flash.<br />

• Chemical savings are achieved because of the pressurized<br />

packages. Chemicals are not lost out the vent.<br />

• Desired air heating efficiency has been achieved. All<br />

retrofitted coils have operated properly and continuously<br />

since installation. Flooding has been eliminated.<br />

• Maintenance costs dropped dramatically with elimination<br />

of condensate flooding, water-hammer and<br />

freezing.<br />

• Personnel safety has improved as steam/condensate<br />

leaks have been reduced.<br />

37<br />

SYSTEM DESIGN