2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Steam Trap Selection<br />

Software<br />

Selecting the best type and size<br />

steam trap is easier today for system<br />

designers who use computer<br />

software programs. The <strong>Spirax</strong><br />

<strong>Sarco</strong> “STEAM NEEDS ANALY-<br />

SIS PROGRAM” is available at<br />

www.snapfour.com and goes a<br />

step further. SNAP not only recommends<br />

and sizes the trap from<br />

input conditions, but also specifies<br />

condensate return pumps,<br />

other necessary auxiliary equipment,<br />

and warns of system<br />

problems that may be encountered.<br />

The SNAP program is<br />

user-friendly, menu-driven software<br />

that accurately calculates<br />

the condensate load for a wide<br />

range of drip, tracing and process<br />

applications (described both by<br />

common name and generic<br />

description.) Significant is the fact<br />

that a SNAP user has the choice<br />

of selecting either a recommended<br />

type of trap or a different type<br />

that may be preferred for any reason.<br />

For all selections, a formal<br />

specification sheet may be printed<br />

which contains additional<br />

information.<br />

Steam Trap Selection<br />

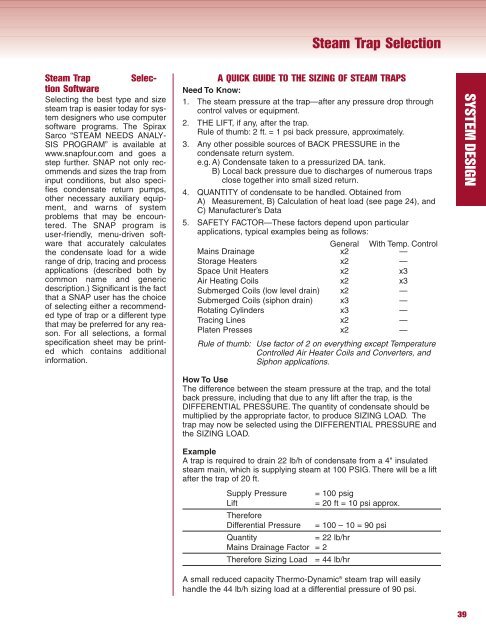

A QUICK GUIDE TO THE SIZING OF STEAM TRAPS<br />

Need To Know:<br />

1. The steam pressure at the trap—after any pressure drop through<br />

control valves or equipment.<br />

2. THE LIFT, if any, after the trap.<br />

Rule of thumb: 2 ft. = 1 psi back pressure, approximately.<br />

3. Any other possible sources of BACK PRESSURE in the<br />

condensate return system.<br />

e.g. A) Condensate taken to a pressurized DA. tank.<br />

B) Local back pressure due to discharges of numerous traps<br />

close together into small sized return.<br />

4. QUANTITY of condensate to be handled. Obtained from<br />

A) Measurement, B) Calculation of heat load (see page 24), and<br />

5.<br />

C) Manufacturer’s Data<br />

SAFETY FACTOR—These factors depend <strong>up</strong>on particular<br />

applications, typical examples being as follows:<br />

Mains Drainage<br />

General<br />

x2<br />

With Temp. Control<br />

—<br />

Storage Heaters x2 —<br />

Space Unit Heaters x2 x3<br />

Air Heating Coils x2 x3<br />

Submerged Coils (low level drain) x2 —<br />

Submerged Coils (siphon drain) x3 —<br />

Rotating Cylinders x3 —<br />

Tracing Lines x2 —<br />

Platen Presses x2 —<br />

Rule of thumb: Use factor of 2 on everything except Temperature<br />

Controlled Air Heater Coils and Converters, and<br />

Siphon applications.<br />

How To Use<br />

The difference between the steam pressure at the trap, and the total<br />

back pressure, including that due to any lift after the trap, is the<br />

DIFFERENTIAL PRESSURE. The quantity of condensate should be<br />

multiplied by the appropriate factor, to produce SIZING LOAD. The<br />

trap may now be selected using the DIFFERENTIAL PRESSURE and<br />

the SIZING LOAD.<br />

Example<br />

A trap is required to drain 22 lb/h of condensate from a 4" insulated<br />

steam main, which is s<strong>up</strong>plying steam at 100 PSIG. There will be a lift<br />

after the trap of 20 ft.<br />

S<strong>up</strong>ply Pressure = 100 psig<br />

Lift<br />

Therefore<br />

= 20 ft = 10 psi approx.<br />

Differential Pressure = 100 – 10 = 90 psi<br />

Quantity = 22 lb/hr<br />

Mains Drainage Factor = 2<br />

Therefore Sizing Load = 44 lb/hr<br />

A small reduced capacity Thermo-Dynamic ® steam trap will easily<br />

handle the 44 lb/h sizing load at a differential pressure of 90 psi.<br />

39<br />

SYSTEM DESIGN