2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Water Valve Sizing<br />

Water valve capacity is directly<br />

related to the square root of the<br />

pressure drop across it, not the<br />

static system pressure. Knowing<br />

the load in GPM water or any<br />

other liquid, the minimum valve<br />

Cv required is calculated from the<br />

allowable pressure drop (∆P):<br />

Cv = GPM S.G.<br />

√ ∆P derived from...<br />

GPM(Water) = Cv √ ∆P<br />

(Other SG Liquids)<br />

GPM = Cv ∆P<br />

√ S.G.<br />

A<br />

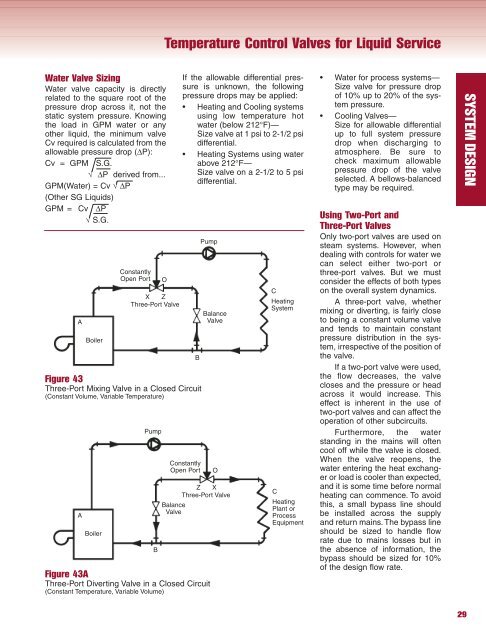

Figure 43<br />

Three-Port Mixing Valve in a Closed Circuit<br />

(Constant Volume, Variable Temperature)<br />

A<br />

Boiler<br />

Boiler<br />

Constantly<br />

Open Port<br />

Pump<br />

Figure 43A<br />

Three-Port Diverting Valve in a Closed Circuit<br />

(Constant Temperature, Variable Volume)<br />

B<br />

Temperature Control Valves for Liquid Service<br />

O<br />

X Z<br />

Three-Port Valve<br />

If the allowable differential pressure<br />

is unknown, the following<br />

pressure drops may be applied:<br />

• Heating and Cooling systems<br />

using low temperature hot<br />

water (below 212°F)—<br />

Size valve at 1 psi to 2-1/2 psi<br />

differential.<br />

• Heating Systems using water<br />

above 212°F—<br />

Size valve on a 2-1/2 to 5 psi<br />

differential.<br />

B<br />

Constantly<br />

Open Port<br />

Pump<br />

Balance<br />

Valve<br />

O<br />

Z X<br />

Three-Port Valve<br />

Balance<br />

Valve<br />

C<br />

Heating<br />

System<br />

C<br />

Heating<br />

Plant or<br />

Process<br />

Equipment<br />

• Water for process systems—<br />

Size valve for pressure drop<br />

of 10% <strong>up</strong> to 20% of the system<br />

pressure.<br />

• Cooling Valves—<br />

Size for allowable differential<br />

<strong>up</strong> to full system pressure<br />

drop when discharging to<br />

atmosphere. Be sure to<br />

check maximum allowable<br />

pressure drop of the valve<br />

selected. A bellows-balanced<br />

type may be required.<br />

Using Two-Port and<br />

Three-Port Valves<br />

Only two-port valves are used on<br />

steam systems. However, when<br />

dealing with controls for water we<br />

can select either two-port or<br />

three-port valves. But we must<br />

consider the effects of both types<br />

on the overall system dynamics.<br />

A three-port valve, whether<br />

mixing or diverting, is fairly close<br />

to being a constant volume valve<br />

and tends to maintain constant<br />

pressure distribution in the system,<br />

irrespective of the position of<br />

the valve.<br />

If a two-port valve were used,<br />

the flow decreases, the valve<br />

closes and the pressure or head<br />

across it would increase. This<br />

effect is inherent in the use of<br />

two-port valves and can affect the<br />

operation of other subcircuits.<br />

Furthermore, the water<br />

standing in the mains will often<br />

cool off while the valve is closed.<br />

When the valve reopens, the<br />

water entering the heat exchanger<br />

or load is cooler than expected,<br />

and it is some time before normal<br />

heating can commence. To avoid<br />

this, a small bypass line should<br />

be installed across the s<strong>up</strong>ply<br />

and return mains. The bypass line<br />

should be sized to handle flow<br />

rate due to mains losses but in<br />

the absence of information, the<br />

bypass should be sized for 10%<br />

of the design flow rate.<br />

29<br />

SYSTEM DESIGN