2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

2000 Hook-up Book - Spirax Sarco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

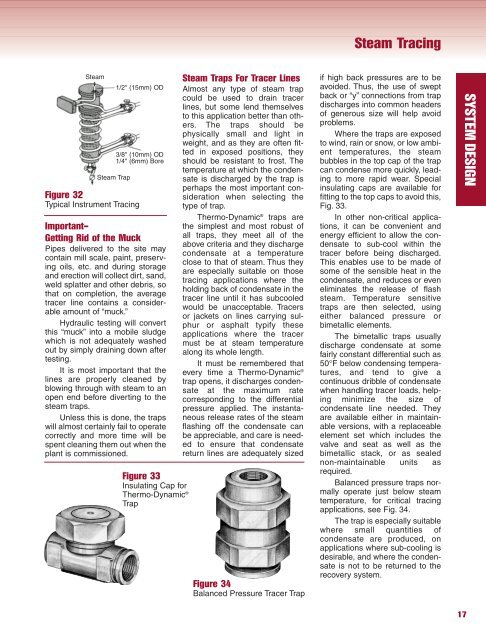

Steam<br />

Steam Trap<br />

1/2" (15mm) OD<br />

3/8" (10mm) OD<br />

1/4" (6mm) Bore<br />

Figure 32<br />

Typical Instrument Tracing<br />

Important—<br />

Getting Rid of the Muck<br />

Pipes delivered to the site may<br />

contain mill scale, paint, preserving<br />

oils, etc. and during storage<br />

and erection will collect dirt, sand,<br />

weld splatter and other debris, so<br />

that on completion, the average<br />

tracer line contains a considerable<br />

amount of “muck.”<br />

Hydraulic testing will convert<br />

this “muck” into a mobile sludge<br />

which is not adequately washed<br />

out by simply draining down after<br />

testing.<br />

It is most important that the<br />

lines are properly cleaned by<br />

blowing through with steam to an<br />

open end before diverting to the<br />

steam traps.<br />

Unless this is done, the traps<br />

will almost certainly fail to operate<br />

correctly and more time will be<br />

spent cleaning them out when the<br />

plant is commissioned.<br />

Figure 33<br />

Insulating Cap for<br />

Thermo-Dynamic ®<br />

Trap<br />

Steam Traps For Tracer Lines<br />

Almost any type of steam trap<br />

could be used to drain tracer<br />

lines, but some lend themselves<br />

to this application better than others.<br />

The traps should be<br />

physically small and light in<br />

weight, and as they are often fitted<br />

in exposed positions, they<br />

should be resistant to frost. The<br />

temperature at which the condensate<br />

is discharged by the trap is<br />

perhaps the most important consideration<br />

when selecting the<br />

type of trap.<br />

Thermo-Dynamic ® traps are<br />

the simplest and most robust of<br />

all traps, they meet all of the<br />

above criteria and they discharge<br />

condensate at a temperature<br />

close to that of steam. Thus they<br />

are especially suitable on those<br />

tracing applications where the<br />

holding back of condensate in the<br />

tracer line until it has subcooled<br />

would be unacceptable. Tracers<br />

or jackets on lines carrying sulphur<br />

or asphalt typify these<br />

applications where the tracer<br />

must be at steam temperature<br />

along its whole length.<br />

It must be remembered that<br />

every time a Thermo-Dynamic ®<br />

trap opens, it discharges condensate<br />

at the maximum rate<br />

corresponding to the differential<br />

pressure applied. The instantaneous<br />

release rates of the steam<br />

flashing off the condensate can<br />

be appreciable, and care is needed<br />

to ensure that condensate<br />

return lines are adequately sized<br />

Figure 34<br />

Balanced Pressure Tracer Trap<br />

Steam Tracing<br />

if high back pressures are to be<br />

avoided. Thus, the use of swept<br />

back or “y” connections from trap<br />

discharges into common headers<br />

of generous size will help avoid<br />

problems.<br />

Where the traps are exposed<br />

to wind, rain or snow, or low ambient<br />

temperatures, the steam<br />

bubbles in the top cap of the trap<br />

can condense more quickly, leading<br />

to more rapid wear. Special<br />

insulating caps are available for<br />

fitting to the top caps to avoid this,<br />

Fig. 33.<br />

In other non-critical applications,<br />

it can be convenient and<br />

energy efficient to allow the condensate<br />

to sub-cool within the<br />

tracer before being discharged.<br />

This enables use to be made of<br />

some of the sensible heat in the<br />

condensate, and reduces or even<br />

eliminates the release of flash<br />

steam. Temperature sensitive<br />

traps are then selected, using<br />

either balanced pressure or<br />

bimetallic elements.<br />

The bimetallic traps usually<br />

discharge condensate at some<br />

fairly constant differential such as<br />

50°F below condensing temperatures,<br />

and tend to give a<br />

continuous dribble of condensate<br />

when handling tracer loads, helping<br />

minimize the size of<br />

condensate line needed. They<br />

are available either in maintainable<br />

versions, with a replaceable<br />

element set which includes the<br />

valve and seat as well as the<br />

bimetallic stack, or as sealed<br />

non-maintainable units as<br />

required.<br />

Balanced pressure traps normally<br />

operate just below steam<br />

temperature, for critical tracing<br />

applications, see Fig. 34.<br />

The trap is especially suitable<br />

where small quantities of<br />

condensate are produced, on<br />

applications where sub-cooling is<br />

desirable, and where the condensate<br />

is not to be returned to the<br />

recovery system.<br />

17<br />

SYSTEM DESIGN