Level 6 Graduate Diploma in Engineering (9210-01) - City & Guilds

Level 6 Graduate Diploma in Engineering (9210-01) - City & Guilds

Level 6 Graduate Diploma in Engineering (9210-01) - City & Guilds

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

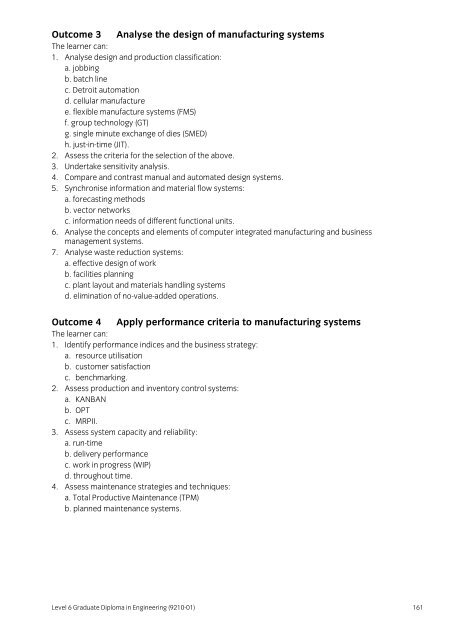

Outcome 3 Analyse the design of manufactur<strong>in</strong>g systems<br />

The learner can:<br />

1. Analyse design and production classification:<br />

a. jobb<strong>in</strong>g<br />

b. batch l<strong>in</strong>e<br />

c. Detroit automation<br />

d. cellular manufacture<br />

e. flexible manufacture systems (FMS)<br />

f. group technology (GT)<br />

g. s<strong>in</strong>gle m<strong>in</strong>ute exchange of dies (SMED)<br />

h. just-<strong>in</strong>-time (JIT).<br />

2. Assess the criteria for the selection of the above.<br />

3. Undertake sensitivity analysis.<br />

4. Compare and contrast manual and automated design systems.<br />

5. Synchronise <strong>in</strong>formation and material flow systems:<br />

a. forecast<strong>in</strong>g methods<br />

b. vector networks<br />

c. <strong>in</strong>formation needs of different functional units.<br />

6. Analyse the concepts and elements of computer <strong>in</strong>tegrated manufactur<strong>in</strong>g and bus<strong>in</strong>ess<br />

management systems.<br />

7. Analyse waste reduction systems:<br />

a. effective design of work<br />

b. facilities plann<strong>in</strong>g<br />

c. plant layout and materials handl<strong>in</strong>g systems<br />

d. elim<strong>in</strong>ation of no-value-added operations.<br />

Outcome 4 Apply performance criteria to manufactur<strong>in</strong>g systems<br />

The learner can:<br />

1. Identify performance <strong>in</strong>dices and the bus<strong>in</strong>ess strategy:<br />

a. resource utilisation<br />

b. customer satisfaction<br />

c. benchmark<strong>in</strong>g.<br />

2. Assess production and <strong>in</strong>ventory control systems:<br />

a. KANBAN<br />

b. OPT<br />

c. MRPII.<br />

3. Assess system capacity and reliability:<br />

a. run-time<br />

b. delivery performance<br />

c. work <strong>in</strong> progress (WIP)<br />

d. throughout time.<br />

4. Assess ma<strong>in</strong>tenance strategies and techniques:<br />

a. Total Productive Ma<strong>in</strong>tenance (TPM)<br />

b. planned ma<strong>in</strong>tenance systems.<br />

<strong>Level</strong> 6 <strong>Graduate</strong> <strong>Diploma</strong> <strong>in</strong> Eng<strong>in</strong>eer<strong>in</strong>g (<strong>9210</strong>-<strong>01</strong>) 161