1956 AMC Hudson Technical Service Manual Supplement

1956 AMC Hudson Technical Service Manual Supplement

1956 AMC Hudson Technical Service Manual Supplement

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14 TECHNICAL SERVICE MANUAL<br />

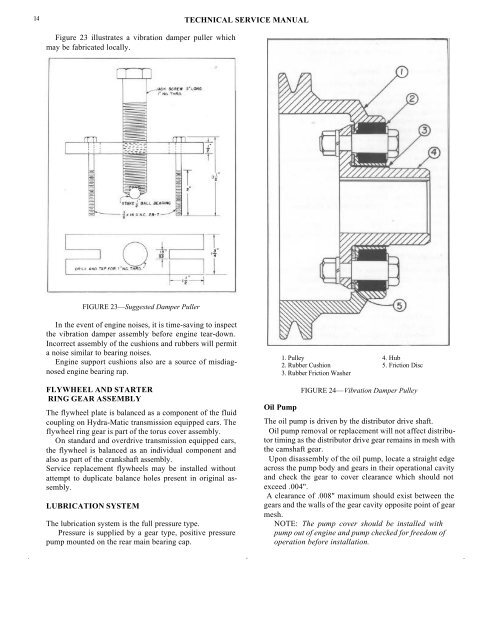

Figure 23 illustrates a vibration damper puller which<br />

may be fabricated locally.<br />

FIGURE 23—Suggested Damper Puller<br />

In the event of engine noises, it is time-saving to inspect<br />

the vibration damper assembly before engine tear-down.<br />

Incorrect assembly of the cushions and rubbers will permit<br />

a noise similar to bearing noises.<br />

Engine support cushions also are a source of misdiagnosed<br />

engine bearing rap.<br />

FLYWHEEL AND STARTER<br />

RING GEAR ASSEMBLY<br />

The flywheel plate is balanced as a component of the fluid<br />

coupling on Hydra-Matic transmission equipped cars. The<br />

flywheel ring gear is part of the torus cover assembly.<br />

On standard and overdrive transmission equipped cars,<br />

the flywheel is balanced as an individual component and<br />

also as part of the crankshaft assembly.<br />

<strong>Service</strong> replacement flywheels may be installed without<br />

attempt to duplicate balance holes present in original assembly.<br />

LUBRICATION SYSTEM<br />

The lubrication system is the full pressure type.<br />

Pressure is supplied by a gear type, positive pressure<br />

pump mounted on the rear main bearing cap.<br />

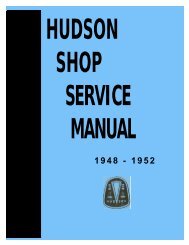

1. Pulley 4. Hub<br />

2. Rubber Cushion 5. Friction Disc<br />

3. Rubber Friction Washer<br />

Oil Pump<br />

FIGURE 24—Vibration Damper Pulley<br />

The oil pump is driven by the distributor drive shaft.<br />

Oil pump removal or replacement will not affect distributor<br />

timing as the distributor drive gear remains in mesh with<br />

the camshaft gear.<br />

Upon disassembly of the oil pump, locate a straight edge<br />

across the pump body and gears in their operational cavity<br />

and check the gear to cover clearance which should not<br />

exceed .004".<br />

A clearance of .008" maximum should exist between the<br />

gears and the walls of the gear cavity opposite point of gear<br />

mesh.<br />

NOTE: The pump cover should be installed with<br />

pump out of engine and pump checked for freedom of<br />

operation before installation.