1956 AMC Hudson Technical Service Manual Supplement

1956 AMC Hudson Technical Service Manual Supplement

1956 AMC Hudson Technical Service Manual Supplement

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

28 TECHNICAL SERVICE MANUAL<br />

it up for maximum output. When pressure becomes high, the<br />

pressure regulator valve is forced outward, directing oil<br />

pressure above the slide to push it down and decrease the<br />

output.<br />

When the slide is up, it delivers maximum output. When<br />

the slide is centered, output is zero.<br />

The torus check valve is held against the pump slide by<br />

spring pressure. When the slide moves down, oil will pass<br />

through the torus check valve and into the cooler passage<br />

from the cooler to the torus feed passage. If the cooler should<br />

become inoperative, oil from the torus check valve will<br />

unseat a ball check held in position by spring pressure and<br />

flow into the torus feed passage.<br />

REAR PUMP<br />

The rear pump is of the fixed displacement gear type and is<br />

driven by the output shaft; therefore, rear pump capacity will<br />

vary with car speed. At idle, the rear pump is not supplying<br />

oil to the transmission and all oil pressure will be supplied<br />

by the front pump.<br />

As the speed of the car increases, the oil from the rear<br />

pump will flow together with the front pump oil through a<br />

passage in the case. Much of the oil pressure requirements<br />

of the transmission will be taken over by the rear pump and<br />

the front pump will compensate by reducing its output.<br />

The basic requirements of a need for a rear pump was the<br />

necessity for oil pressure to supply the transmission in the<br />

event of a need for a push to start the vehicle.<br />

ACCUMULATOR<br />

To effect a smooth apply of the rear clutch, 2-3 oil being<br />

directed to the rear clutch apply piston is also directed to an<br />

accumulator. The accumulator contains a piston with heavy<br />

springs holding the piston in the down position which is<br />

opposing 2-3 oil directed to the other side of the piston. Oil<br />

from the 2-3 shift valve will move the accumulator piston<br />

against spring and oil pressure and also apply the rear clutch.<br />

Since the flow of oil to the accumulator and clutch apply<br />

piston is restricted, the accumulator is capable of collecting<br />

any oil that does flow through the restriction at the pressure<br />

valve which is required to move it. This maintains the<br />

pressure acting on the clutch piston, at a value below line<br />

pressure, until the accumulator is full. At that time, the<br />

pressure rises to line pressure. The engagement of the clutch<br />

must be completed before the accumulator is full to produce<br />

smooth shifts at the lower apply pressures.<br />

Clutch apply requirements will vary with throttle and load<br />

conditions. The accumulator is a factor in rear clutch engagement;<br />

its operation is varied accordingly by directing<br />

T.V. pressure to assist the spring in resisting 2-3 oil pressure.<br />

This T.V. pressure to the accumulator is regulated by a<br />

trimmer valve located in the accumulator body, held in the<br />

open position by spring and closed by T.V. pressure, thereby<br />

regulating T.V. pressure to the accumulator as the need<br />

requires.<br />

LOW SERVO<br />

The low servo located in the accumulator body is used to<br />

apply the low range band when the selector lever is moved<br />

to the "L" range position. Oil is directed from the manual<br />

valve to the servo to apply the low range band which holds<br />

the rear unit internal gear and prevents the vehicle from<br />

overrunning the rear sprag clutch when "L" range is being<br />

used for engine braking.<br />

HOW TO OPERATE THE FLASHAWAY HYDRA-MATIC<br />

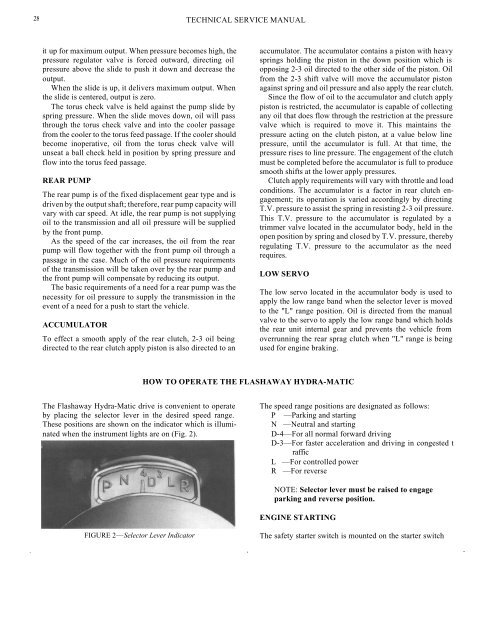

The Flashaway Hydra-Matic drive is convenient to operate<br />

by placing the selector lever in the desired speed range.<br />

These positions are shown on the indicator which is illuminated<br />

when the instrument lights are on (Fig. 2).<br />

The speed range positions are designated as follows:<br />

P —Parking and starting<br />

N —Neutral and starting<br />

D-4—For all normal forward driving<br />

D-3—For faster acceleration and driving in congested t<br />

raffic<br />

L —For controlled power<br />

R —For reverse<br />

NOTE: Selector lever must be raised to engage<br />

parking and reverse position.<br />

ENGINE STARTING<br />

FIGURE 2—Selector Lever Indicator<br />

The safety starter switch is mounted on the starter switch