East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

53<br />

GDP Potential<br />

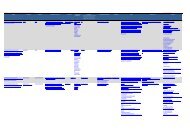

The economic decline of the forestry sector in <strong>East</strong> <strong>Kalimantan</strong> can be reversed through<br />

raising productivity and investing in downstream activities. These moves would increase the<br />

forestry sector’s GDP by IDR 16 trillion by 2030 (EXHIBIT 31). The initiatives described earlier will<br />

reduce emissions from our current logging and harvesting activities, but such efforts should be<br />

complemented with efforts to extract more value from these activities. Currently, much of the<br />

felled timber from logging is left as waste in the forest: thiscould be further processed. After forests<br />

are converted to plantations, there are different opportunities to raise productivity within those<br />

concessions. And finally, much of <strong>East</strong> <strong>Kalimantan</strong>’s timber is exported to Sumatra and Java<br />

where it is processed into higher value products such as pulp or furniture. <strong>East</strong> <strong>Kalimantan</strong> has the<br />

opportunity to capture a larger share of the downstream value-add going forward.<br />

Yield improvements in HTI, and increasing value added production could<br />

increase the GDP of the forestry sector to IDR 19.3 trillion by 2030<br />

<strong>East</strong> <strong>Kalimantan</strong>’s real GDP forecast<br />

IDR Trillions<br />

20<br />

15<br />

10<br />

5<br />

0<br />

2005<br />

SOURCE: team analysis<br />

<strong>Environmentally</strong><br />

<strong>Sustainable</strong><br />

<strong>Development</strong><br />

<strong>Strategy</strong><br />

Business<br />

as usual<br />

DRAFT<br />

10<br />

15<br />

20<br />

Improving timber utilization could yield IDR 0.7 trillion in additional GDP. Currently, logging<br />

operations produce large volumes of waste. The logging companies currently sell to domestic<br />

plywood and veneer mills or other solid wood applications. These buyers are interested in only<br />

large diameter logs. Thus, large volumes of small-diameter wood (e.g., tree crowns) and wood<br />

residues are left behind in the forest after the trees are cut. A more efficient approach is to fully<br />

utilize the felled trees and thus gain higher revenues from a given land area. A common approach in<br />

Europe, North America, and Brazil is to use large-diameter wood for high-value applications (as is<br />

already done in <strong>East</strong> <strong>Kalimantan</strong>), but then to sell small-diameter wood and wood residue for lowervalue<br />

applications like pulp and paper, board manufacturing, and the production of wood chips<br />

and wood pellets (EXHIBIT 32).<br />

25<br />

2030<br />

CAGR<br />

5%<br />

-1%<br />

Exhibit 31<br />

Growth rates in <strong>East</strong> <strong>Kalimantan</strong>’s timber plantations could be substantially improved<br />

and idle plantations brought back into production. As noted earlier, growth rates in <strong>East</strong><br />

<strong>Kalimantan</strong>’s industrial pulpwood plantations are low compared with best practice benchmarks in<br />

other parts of Indonesia. The annual growth rate is around 20 cubic meters per ha, while up to 40