East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

75<br />

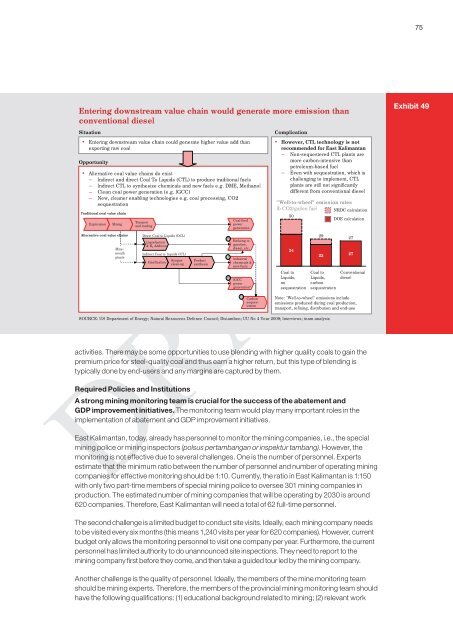

Entering downstream value chain would generate more emission than<br />

conventional diesel<br />

Situation<br />

▪ Entering downstream value chain could generate higher value add than<br />

exporting raw coal<br />

Opportunity<br />

▪ Alternative coal value chains do exist<br />

– Indirect and direct Coal To Liquids (CTL) to produce traditional fuels<br />

– Indirect CTL to synthesize chemicals and new fuels e.g. DME, Methanol<br />

– Clean coal power generation (e.g. IGCC)<br />

– New, cleaner enabling technologies e.g. coal processing, CO2<br />

sequestration<br />

Traditional coal value chain<br />

Exploration<br />

Mining<br />

Alternative coal value chains<br />

Trasport<br />

and trading<br />

Direct Coal to Liquids (DCL)<br />

Liquefaction<br />

&H 2 Addition<br />

Indirect Coal to Liquids (ICL)<br />

Gasification<br />

Syngas<br />

clean-up<br />

Product<br />

synthesis<br />

Coal-fired<br />

power<br />

generation<br />

a<br />

Refining to<br />

gasoline,<br />

diesel, etc.<br />

b<br />

Industrial<br />

chemicals &<br />

new fuels<br />

c<br />

IGCC<br />

power<br />

generation*<br />

Minemouth<br />

plants<br />

d<br />

Carbon<br />

sequestration<br />

Complication<br />

▪ However, CTL technology is not<br />

recommended for <strong>East</strong> <strong>Kalimantan</strong><br />

– Non-sequestered CTL plants are<br />

more carbon-intensive than<br />

petroleum-based fuel<br />

– Even with sequestration, which is<br />

challenging to implement, CTL<br />

plants are still not significantly<br />

different from conventional diesel<br />

"Well-to-wheel" emission rates<br />

lb CO2/gallon fuel NRDC calculation<br />

50<br />

DOE calculation<br />

Coal to<br />

Liquids,<br />

no<br />

sequestration<br />

SOURCE: US Department of Energy; Natural Resources Defence Council; Distamben; UU No 4 Year 2009; Interviews; team analysis<br />

activities. There may be some opportunities to use blending with higher quality coals to gain the<br />

premium price for steel-quality coal and thus earn a higher return, but this type of blending is<br />

typically done by end-users and any margins are captured by them.<br />

Required Policies and Institutions<br />

A strong mining monitoring team is crucial for the success of the abatement and<br />

GDP improvement initiatives. The monitoring team would play many important roles in the<br />

implementation of abatement and GDP improvement initiatives.<br />

<strong>East</strong> <strong>Kalimantan</strong>, today, already has personnel to monitor the mining companies, i.e., the special<br />

mining police or mining inspectors (polsus pertambangan or inspektur tambang). However, the<br />

monitoring is not effective due to several challenges. One is the number of personnel. Experts<br />

estimate that the minimum ratio between the number of personnel and number of operating mining<br />

companies for effective monitoring should be 1:10. Currently, the ratio in <strong>East</strong> <strong>Kalimantan</strong> is 1:150<br />

with only two part-time members of special mining police to oversee 301 mining companies in<br />

production. The estimated number of mining companies that will be operating by 2030 is around<br />

620 companies. Therefore, <strong>East</strong> <strong>Kalimantan</strong> will need a total of 62 full-time personnel.<br />

DRAFT<br />

34<br />

29<br />

23<br />

Coal to<br />

Liquids,<br />

carbon<br />

sequestration<br />

27<br />

27<br />

Conventional<br />

diesel<br />

Note: "Well-to-wheel" emissions include<br />

emissions produced during coal production,<br />

transport, refining, distribution and end-use<br />

Exhibit 49<br />

The second challenge is a limited budget to conduct site visits. Ideally, each mining company needs<br />

to be visited every six months (this means 1,240 visits per year for 620 companies). However, current<br />

budget only allows the monitoring personnel to visit one company per year. Furthermore, the current<br />

personnel has limited authority to do unannounced site inspections. They need to report to the<br />

mining company first before they come, and then take a guided tour led by the mining company.<br />

Another challenge is the quality of personnel. Ideally, the members of the mine monitoring team<br />

should be mining experts. Therefore, the members of the provincial mining monitoring team should<br />

have the following qualifications: (1) educational background related to mining; (2) relevant work