East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

55<br />

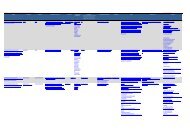

Downstream manufacturing would increase economic value of the forestry<br />

sector, however wood supply needs to come from sustainable resources<br />

Pulp<br />

1 and<br />

paper<br />

Wood<br />

2<br />

pellets<br />

High value<br />

3<br />

furniture<br />

Description<br />

▪ A total of 300,000 ha of plantations required to produce 2 million tons of<br />

hardwood market pulp<br />

▪ Demand for pulp is expected to increase steadily in China and India<br />

▪ 2 millions t of pulp are worth USD 1.5 billion at current market prices and<br />

would result in approx. 100,000 jobs<br />

▪ Wood pellets can be produced from wood residues of the pulp and plywood<br />

industry<br />

▪ Excess steam and electricity from nearby pulp mills will make pellet<br />

production extremely cost competitive<br />

▪ Steady demand in Europe and potentially china and Japan<br />

▪ FSC certified furniture could provide high value export opportunities from<br />

<strong>East</strong> <strong>Kalimantan</strong>’s HPHs<br />

▪ However, price premiums for certified products are still uncertain<br />

Downstream manufacturing investment cannot run ahead of<br />

investment in sustainable and certified sources of timber,<br />

whether from new plantations on degraded land or as a<br />

result of better productivity from existing plantations<br />

• Pulp and paper: In the pulp and paper sector, Indonesia has a proven track record of being<br />

world class in terms of production. The pulp mills in Sumatra are amongst the world’s largest<br />

and lowest cost production sites.,They are extremely controversial from an environmental<br />

perspective as insufficient supply from plantations being heavily supplemented by timber<br />

cleared from natural forests. <strong>Sustainable</strong> pulp production in <strong>East</strong> <strong>Kalimantan</strong> would be<br />

competitive globally given its low costs and advantages of its location relative to the India and<br />

China markets for pulp.<br />

DRAFT<br />

As described above, the area of <strong>East</strong> <strong>Kalimantan</strong>’s industrial timber plantations is large enough<br />

to supply more than 20 million cubic meters of pulpwood if managed with best international<br />

practices. This volume would meet the full production requirements for the existing Kertas<br />

Nusantara pulp mill in Berau, approximately 6 million cubic meters per year, as well as provide<br />

another 2 million tons of market pulp.<br />

The production of market pulp would result in a significant contribution to <strong>East</strong><br />

<strong>Kalimantan</strong>’s GDP and also provide significant working opportunities for our people<br />

(EXHIBIT 34). Prices for market pulp recovered quickly from the dip during the economic<br />

crisis in 2009 and have reached levels of nearly USD 800 per ton delivered to Europe or North<br />

America. At this price level, the production of 2 million tons of market pulp could result in<br />

revenues of USD 1.6 billion p.a. The number of employees required to run a pulp mill and the<br />

adjacent plantations is significant as well. Pulp mills in Sumatra employ between 30,000 and<br />

50,000 people for the production of 1 million tons of pulp.<br />

Exhibit 33<br />

Significant safeguards would need to be put in place before the expansion of the pulp<br />

and paper production capacity. Increasing the demand for timber without first ensuring a<br />

sustainable supply will only lead to increased overlogging and deforestation. There are several<br />

options to ensure the pulp and paper mills use only timber from sustainable plantations.