East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

East Kalimantan Environmentally Sustainable Development Strategy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

54<br />

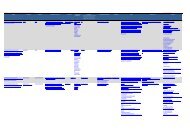

Exhibit 32<br />

Utilizing trees fully can increase the value from logging<br />

activities and decrease harvesting waste<br />

SOURCE: Institute of Forest Utilization Freiburg, team analysis<br />

Not utilized<br />

Veneer, ply- sawnwood<br />

Conventional utilization<br />

Full tree utilization<br />

ILLUSTRATIVE<br />

cubic meters per ha is achieved in other parts of Indonesia. Given differences in soil quality, a more<br />

conservative range of 25 to 30 cubic meters per ha is targeted.<br />

Increased yields could also come from bringing idle plantations back into production. At present,<br />

<strong>East</strong> <strong>Kalimantan</strong>’s pulpwood plantations cover an area of approximately 800,000 ha, the majority<br />

of which were established during the 1990s. In line with current environmental regulations,<br />

approximately 160,000 ha have to be set aside for nature conservation (e.g., watershed protection<br />

and wildlife corridors) while the remaining area could be used for economic purposes. In theory,<br />

these 640,000 ha could yield an annual volume of approximately 23 million cubic meters, 17 more<br />

than enough to supply a viable forest products industry. However, currently only 165,000 ha are<br />

actually planted, while the remaining area is degraded, and lies idle. Low productivity, and this<br />

low rate of planting mean <strong>East</strong> <strong>Kalimantan</strong>’s annual harvest is only 0.7 million cubic meters. The<br />

continued conversion of natural forests into plantations is unnecessary for growth in the sector.<br />

Instead of expanding the overall plantation area, the focus should be on improving yieldsand<br />

ensuring that the area set aside for industrial timber plantations is fully utilized. Realizing this<br />

approach could increase annual sustainable wood production and the economic contribution from<br />

production forests by a factor of ten.<br />

DRAFT<br />

Wood pellets<br />

Pulp wood<br />

Veneer, ply- sawnwood<br />

Downstream manufacturing (IDR 8.5 trillion): Several opportunities exist for the industry<br />

to move downstream into higher value-added production businesses. Based on future market<br />

developments, the largest opportunities are likely to be in pulp and paper and wood pellet<br />

production, which ideally would be located in close proximity of each other to lower costs<br />

of logistics, raw material, and energy. Additional opportunities for niche companies exist in<br />

production of high-value furniture (EXHIBIT 33).<br />

17 Assuming plantations planted with Acacia maginum and Eucalyptus species