Editorial & Advisory Board - Acta Technica Corviniensis

Editorial & Advisory Board - Acta Technica Corviniensis

Editorial & Advisory Board - Acta Technica Corviniensis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

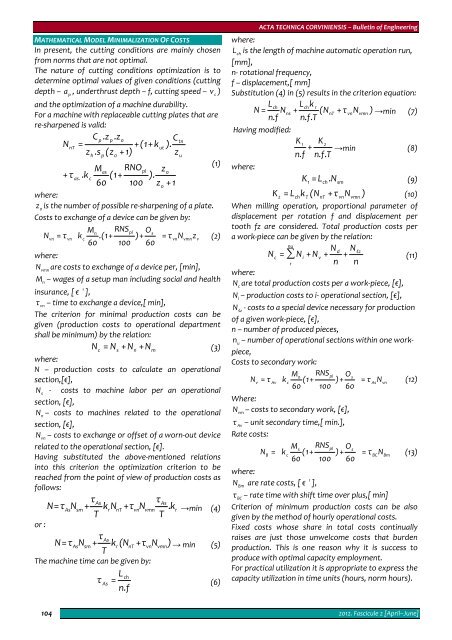

MATHEMATICAL MODEL MINIMALIZATION OF COSTS<br />

In present, the cutting conditions are mainly chosen<br />

from norms that are not optimal.<br />

The nature of cutting conditions optimization is to<br />

determine optimal values of given conditions (cutting<br />

depth – a<br />

p<br />

, underthrust depth – f, cutting speed – v)<br />

c<br />

and the optimization of a machine durability.<br />

For a machine with replaceable cutting plates that are<br />

re‐sharpened is valid:<br />

C<br />

p<br />

.z<br />

p<br />

.z<br />

0<br />

C<br />

tn<br />

NnT<br />

=<br />

+ (1+<br />

kut<br />

).<br />

zh<br />

.s<br />

p<br />

(z0<br />

+ 1) zu<br />

M RNO<br />

(1)<br />

as<br />

pl z0<br />

+ τ<br />

as.<br />

.k<br />

c<br />

(1+<br />

).<br />

60 100 z0<br />

+ 1<br />

where:<br />

z0<br />

is the number of possible re‐sharpening of a plate.<br />

Costs to exchange of a device can be given by:<br />

M RNS<br />

n<br />

pl Os<br />

N<br />

vn<br />

= τvn<br />

kc<br />

.(1+<br />

) + = τvnNvmnzv<br />

(2)<br />

60 100 60<br />

where:<br />

Nvmn<br />

are costs to exchange of a device per, [min],<br />

M<br />

n<br />

– wages of a setup man including social and health<br />

1<br />

insurance, [ € ],<br />

τ<br />

vn<br />

– time to exchange a device,[ min],<br />

The criterion for minimal production costs can be<br />

given (production costs to operational department<br />

shall be minimum) by the relation:<br />

N<br />

c<br />

= Ns<br />

+ Nn<br />

+ Nm<br />

(3)<br />

where:<br />

N – production costs to calculate an operational<br />

section,[€],<br />

N<br />

s<br />

‐ costs to machine labor per an operational<br />

section, [€],<br />

N<br />

n<br />

– costs to machines related to the operational<br />

section, [€],<br />

N<br />

vn<br />

– costs to exchange or offset of a worn‐out device<br />

related to the operational section, [€].<br />

Having substituted the above‐mentioned relations<br />

into this criterion the optimization criterion to be<br />

reached from the point of view of production costs as<br />

follows:<br />

or :<br />

τ<br />

N +<br />

T<br />

As<br />

As<br />

= τAsNsm<br />

+ krNnT<br />

τvnNvmn<br />

. kr<br />

→min (4)<br />

τAs<br />

N= τAs Nsm<br />

+ kr<br />

(NnT<br />

+ τvnNvmn)<br />

→ min (5)<br />

T<br />

The machine time can be given by:<br />

Lch<br />

τ<br />

As<br />

= (6)<br />

n.f<br />

τ<br />

T<br />

ACTA TECHNICA CORVINIENSIS – Bulletin of Engineering<br />

where:<br />

Lch<br />

is the length of machine automatic operation run,<br />

[mm],<br />

n‐ rotational frequency,<br />

f – displacement,[ mm]<br />

Substitution (4) in (5) results in the criterion equation:<br />

Lch<br />

Lchk<br />

r<br />

N = Nns<br />

+ (NnT<br />

+ τvnNvmn<br />

) →min (7)<br />

n.f n.f.T<br />

Having modified:<br />

where:<br />

K<br />

K1<br />

K<br />

2<br />

+ →min (8)<br />

n.f n.f.T<br />

1<br />

Lch<br />

. Nsm<br />

2<br />

Lchk<br />

T<br />

(NnT<br />

+ τvn<br />

K = (9)<br />

= N ) (10)<br />

When milling operation, proportional parameter of<br />

displacement per rotation f and displacement per<br />

tooth fz are considered. Total production costs per<br />

a work‐piece can be given by the relation:<br />

N N<br />

vmn<br />

∑ nu d šz<br />

c<br />

= Ni<br />

+ Nv<br />

+<br />

(11)<br />

1 n n<br />

N +<br />

where:<br />

Nare total production costs per a work‐piece, [€],<br />

c<br />

N – production costs to i‐ operational section, [€],<br />

i<br />

Nšz<br />

‐ costs to a special device necessary for production<br />

of a given work‐piece, [€],<br />

n – number of produced pieces,<br />

n<br />

u<br />

– number of operational sections within one workpiece,<br />

Costs to secondary work:<br />

M RNS<br />

0<br />

pl Os<br />

N<br />

v<br />

= τ<br />

Av<br />

k<br />

c<br />

(1+<br />

) + = τ<br />

AsNvn<br />

(12)<br />

60 100 60<br />

Where:<br />

N – costs to secondary work, [€],<br />

vm<br />

τ<br />

Av<br />

– unit secondary time,[ min.],<br />

Rate costs:<br />

M RNS<br />

s<br />

pl Os<br />

N<br />

B<br />

= k<br />

c<br />

(1+<br />

) + = τBCNBm<br />

(13)<br />

60 100 60<br />

where:<br />

1<br />

N are rate costs, [ € ],<br />

Bm<br />

τ<br />

BC<br />

– rate time with shift time over plus,[ min]<br />

Criterion of minimum production costs can be also<br />

given by the method of hourly operational costs.<br />

Fixed costs whose share in total costs continually<br />

raises are just those unwelcome costs that burden<br />

production. This is one reason why it is success to<br />

produce with optimal capacity employment.<br />

For practical utilization it is appropriate to express the<br />

capacity utilization in time units (hours, norm hours).<br />

104<br />

2012. Fascicule 2 [April–June]