Editorial & Advisory Board - Acta Technica Corviniensis

Editorial & Advisory Board - Acta Technica Corviniensis

Editorial & Advisory Board - Acta Technica Corviniensis

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Significant increase in the concentration of carbon at<br />

the beginning of the combined zone can be seen from<br />

Figure 3, where it reaches the level of 0,52% and slightly<br />

decreases at the end of the carbonitrided zone, going to<br />

about 0,48 %. The distribution of the nitrogen in the<br />

carbonitrided zone changes gradually and its<br />

concentration at the end of the combined zone reaches<br />

the level of 7%, while at the beginning of the combined<br />

zone it is about 12,2 %. Under this mode of treatment the<br />

highest level of nitrogen concentration 12.2 % is achieved<br />

in the combined zone and the most gradual change of<br />

the content of nitrogen and carbon in the formed layer<br />

occur in comparison to all the other modes of ion<br />

carbonitriding of 25CrMnSiNiMo steel.<br />

ARMCO‐IRON<br />

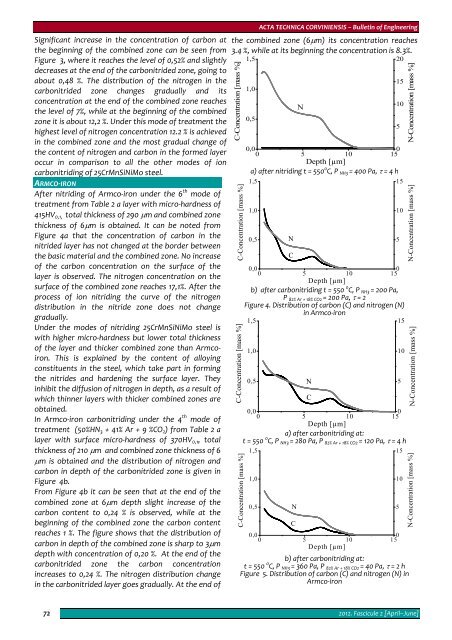

After nitriding of Armco‐iron under the 6 th mode of<br />

treatment from Table 2 a layer with micro‐hardness of<br />

415HV 0,1, total thickness of 290 μm and combined zone<br />

thickness of 6μm is obtained. It can be noted from<br />

Figure 4a that the concentration of carbon in the<br />

nitrided layer has not changed at the border between<br />

the basic material and the combined zone. No increase<br />

of the carbon concentration on the surface of the<br />

layer is observed. The nitrogen concentration on the<br />

surface of the combined zone reaches 17,1%. After the<br />

process of ion nitriding the curve of the nitrogen<br />

distribution in the nitride zone does not change<br />

gradually.<br />

Under the modes of nitriding 25CrMnSiNiMo steel is<br />

with higher micro‐hardness but lower total thickness<br />

of the layer and thicker combined zone than Armcoiron.<br />

This is explained by the content of alloying<br />

constituents in the steel, which take part in forming<br />

the nitrides and hardening the surface layer. They<br />

inhibit the diffusion of nitrogen in depth, as a result of<br />

which thinner layers with thicker combined zones are<br />

obtained.<br />

In Armco‐iron carbonitriding under the 4 th mode of<br />

treatment (50%HN 3 + 41% Ar + 9 %CO 2 ) from Table 2 a<br />

layer with surface micro‐hardness of 370HV 0,1 , total<br />

thickness of 210 μm and combined zone thickness of 6<br />

μm is obtained and the distribution of nitrogen and<br />

carbon in depth of the carbonitrided zone is given in<br />

Figure 4b.<br />

From Figure 4b it can be seen that at the end of the<br />

combined zone at 6μm depth slight increase of the<br />

carbon content to 0,24 % is observed, while at the<br />

beginning of the combined zone the carbon content<br />

reaches 1 %. The figure shows that the distribution of<br />

carbon in depth of the combined zone is sharp to 3μm<br />

depth with concentration of 0,20 %. At the end of the<br />

carbonitrided zone the carbon concentration<br />

increases to 0,24 %. The nitrogen distribution change<br />

in the carbonitrided layer goes gradually. At the end of<br />

ACTA TECHNICA CORVINIENSIS – Bulletin of Engineering<br />

the combined zone (6μm) its concentration reaches<br />

3.4 %, while at its beginning the concentration is 8.3%.<br />

C-Concentration [mass %]<br />

C-Concentration [mass %]<br />

C-Concentration [mass %]<br />

C-Concentration [mass %]<br />

1,5<br />

1,0<br />

0,5<br />

N<br />

0,0<br />

0 5 10<br />

0<br />

15<br />

Depth [µm]<br />

а) after nitriding t = 550 0 C, P NH3 = 400 Pa, τ = 4 h<br />

1,5<br />

1,0<br />

0,5<br />

N<br />

C<br />

0,0<br />

0<br />

0 5 10 15<br />

Depth [µm]<br />

b) after carbonitriding t = 550 0 C, P NH3 = 200 Pa,<br />

P 82% Ar + 18% CO2 = 200 Pa, τ = 2<br />

Figure 4. Distribution of carbon (С) and nitrogen (N)<br />

in Armco‐iron<br />

1,5<br />

15<br />

1,0<br />

0,5<br />

0,0<br />

0<br />

0 5 10 15<br />

Depth [µm]<br />

a) after carbonitriding at:<br />

t = 550 0 C, P NH3 = 280 Pa, P 82% Ar + 18% CO2 = 120 Pa, τ = 4 h<br />

1,5<br />

1,0<br />

0,5<br />

N<br />

C<br />

N<br />

C<br />

0,0<br />

0<br />

0 5 10 15<br />

Depth [µm]<br />

b) after carbonitriding at:<br />

t = 550 0 C, P NH3 = 360 Pa, P 82% Ar + 18% CO2 = 40 Pa, τ = 2 h<br />

Figure 5. Distribution of carbon (С) and nitrogen (N) in<br />

Armco‐iron<br />

20<br />

15<br />

10<br />

5<br />

15<br />

10<br />

5<br />

10<br />

5<br />

15<br />

10<br />

5<br />

N-Concentration [mass %]<br />

N-Concentration [mass %]<br />

N-Concentration [mass %]<br />

N-Concentration [mass %]<br />

72<br />

2012. Fascicule 2 [April–June]