Super Smart Ball Bushing Bearing - Hollin Applications

Super Smart Ball Bushing Bearing - Hollin Applications

Super Smart Ball Bushing Bearing - Hollin Applications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

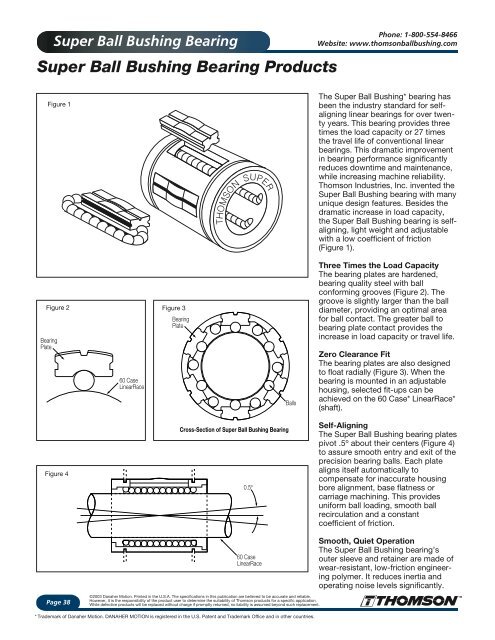

<strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> <strong>Bearing</strong><strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> <strong>Bearing</strong> ProductsPhone: 1-800-554-8466Website: www.thomsonballbushing.comFigure 1The <strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong>* bearing hasbeen the industry standard for selfaligninglinear bearings for over twentyyears. This bearing provides threetimes the load capacity or 27 timesthe travel life of conventional linearbearings. This dramatic improvementin bearing performance significantlyreduces downtime and maintenance,while increasing machine reliability.Thomson Industries, Inc. invented the<strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> bearing with manyunique design features. Besides thedramatic increase in load capacity,the <strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> bearing is selfaligning,light weight and adjustablewith a low coefficient of friction(Figure 1).Figure 2<strong>Bearing</strong>Plate60 CaseLinearRaceFigure 3<strong>Bearing</strong>Plate<strong>Ball</strong>sThree Times the Load CapacityThe bearing plates are hardened,bearing quality steel with ballconforming grooves (Figure 2). Thegroove is slightly larger than the balldiameter, providing an optimal areafor ball contact. The greater ball tobearing plate contact provides theincrease in load capacity or travel life.Zero Clearance FitThe bearing plates are also designedto float radially (Figure 3). When thebearing is mounted in an adjustablehousing, selected fit-ups can beachieved on the 60 Case* LinearRace*(shaft).Figure 4Cross-Section of <strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> <strong>Bearing</strong>0.5º60 CaseLinearRaceSelf-AligningThe <strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> bearing platespivot .5º about their centers (Figure 4)to assure smooth entry and exit of theprecision bearing balls. Each platealigns itself automatically tocompensate for inaccurate housingbore alignment, base flatness orcarriage machining. This providesuniform ball loading, smooth ballrecirculation and a constantcoefficient of friction.Smooth, Quiet OperationThe <strong>Super</strong> <strong>Ball</strong> <strong>Bushing</strong> bearing’souter sleeve and retainer are made ofwear-resistant, low-friction engineeringpolymer. It reduces inertia andoperating noise levels significantly.Page 38©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.