Super Smart Ball Bushing Bearing - Hollin Applications

Super Smart Ball Bushing Bearing - Hollin Applications

Super Smart Ball Bushing Bearing - Hollin Applications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

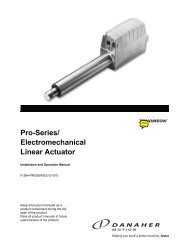

XR <strong>Ball</strong> <strong>Bushing</strong> <strong>Bearing</strong>sPhone: 1-800-554-8466Website: www.thomsonballbushing.comXR <strong>Ball</strong> <strong>Bushing</strong> <strong>Bearing</strong> ProductsXR <strong>Ball</strong> <strong>Bushing</strong>* bearing products provide five times the loadcapacity or 125 times the travel life and three times the rigidity ofconventional linear bearings. These improvements are centeredaround four technologically advanced components, the XR <strong>Ball</strong><strong>Bushing</strong> bearing, the XPBO <strong>Ball</strong> <strong>Bushing</strong> pillow block, the XL 60Case* LinearRace* (shaft) and the XSR 60 Case LinearRace supportrail.DEFLECTION (INCHES)0.00350.00300.00250.00200.00150.00100.0005XSR 60 Case LinearRace Support RailXR 32 (2")XL 60 CaseLinearRaceXBPOExtra-RigidOpen PillowBlock0.00000 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000RADIAL Radial LOAD Load (POUNDS) lb fDEFLECTION CURVESXR 48 (3")Figure 1Figure 2XR <strong>Ball</strong> <strong>Bushing</strong> <strong>Bearing</strong>The dramatic increase in load capacity and/ortravel life is provided by the XR <strong>Ball</strong> <strong>Bushing</strong> bearing'sadvanced plate design. Each ball conformingbearing plate is precision ground providingsmooth and virtually friction free linear movement.The bearing plate length has also been maximizedto increase the number of rolling elements in theload carrying zone. The position of each XR bearingplate helps to maximize the load capacity inboth pull-off and down loading conditions.XPBO <strong>Ball</strong> <strong>Bushing</strong> Pillow BlockEach XR <strong>Ball</strong> <strong>Bushing</strong> bearing can be housed ina rigid ductile iron pillow block (Figure 1). TheXPBO pillow block provides the stiffness requiredin high load applications (Figure 2). Each XPBO isequipped with four mounting holes for easyassembly to the table surface.XL 60 Case LinearRaceAvailable factory mounted to XSR 60 CaseLinearRace support rail is a hardened andprecision ground 60 Case LinearRace (Figure 1).Each 60 Case LinearRace is ground to a surfacefinish less than 10 Ra microinch and is straight to.001 inch per foot cumulative. Roundness of each60 Case LinearRace is controlled through proprietarytechniques that results in a roundness of 80millionths of an inch. Each XL 60 Case LinearRaceis held to these world class quality standard toassure maximum system performance and travellife.XSR 60 Case LinearRace Support RailsRigidity always starts by continuously supportingthe 60 Case LinearRace and bearing system(Figure 1). The large ductile iron alloy crosssectionof the XSR provides maximum rigidity andstiffness (Figure 2). The increased number ofstandard 60 Case LinearRace mounting holes addfurther stiffness and stability to the system.The RoundRail AdvantageThe RoundRail Advantage is the inherent ability ofan XR <strong>Ball</strong> <strong>Bushing</strong> bearing system to accommodatetorsional misalignment (caused by inaccuraciesin carriage or base machining or by machinedeflection) with little increase in stress to bearingcomponents. Installation time and cost are minimizedand system performance is maximized.Page 96©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.