Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

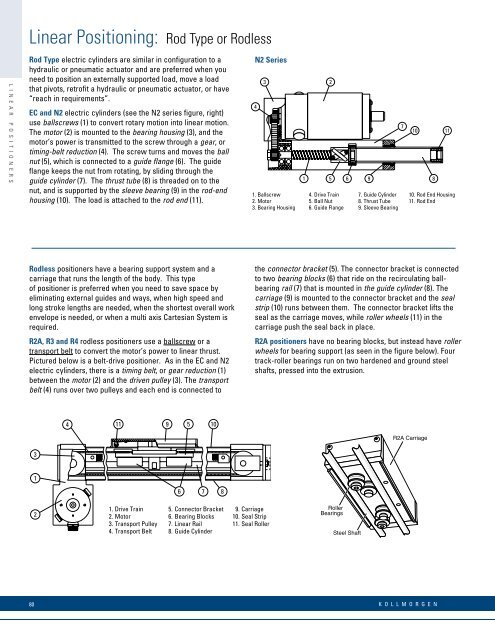

<strong>Linear</strong> Positioning: Rod Type or RodlessL I N E A R P O S I T I O N E R SRod Type electric cylinders are similar in configuration to ahydraulic or pneumatic actuator and are preferred wh<strong>en</strong> youneed to position an externally supported load, move a loadthat pivots, retrofit a hydraulic or pneumatic actuator, or have“reach in requirem<strong>en</strong>ts”.EC and N2 electric cylinders (see the N2 series figure, right)use ballscrews (1) to convert rotary motion into linear motion.The motor (2) is mounted to the bearing housing (3), and themotor’s power is transmitted to the screw through a gear, ortiming-belt reduction (4). The screw turns and moves the ballnut (5), which is connected to a guide flange (6). The guideflange keeps the nut from rotating, by sliding through theguide cylinder (7). The thrust tube (8) is threaded on to th<strong>en</strong>ut, and is supported by the sleeve bearing (9) in the rod-<strong>en</strong>dhousing (10). The load is attached to the rod <strong>en</strong>d (11).N2 Series431. Ballscrew2. Motor3. Bearing Housing125 64. Drive Train5. Ball Nut6. Guide Flange797. Guide Cylinder8. Thrust Tube9. Sleeve Bearing10 11810. Rod End Housing11. Rod EndRodless positioners have a bearing support system and acarriage that runs the l<strong>en</strong>gth of the body. This typeof positioner is preferred wh<strong>en</strong> you need to save space byeliminating external guides and ways, wh<strong>en</strong> high speed andlong stroke l<strong>en</strong>gths are needed, wh<strong>en</strong> the shortest overall work<strong>en</strong>velope is needed, or wh<strong>en</strong> a multi axis Cartesian System isrequired.R2A, R3 and R4 rodless positioners use a ballscrew or atransport belt to convert the motor’s power to linear thrust.Pictured below is a belt-drive positioner. As in the EC and N2electric cylinders, there is a timing belt, or gear reduction (1)betwe<strong>en</strong> the motor (2) and the driv<strong>en</strong> pulley (3). The transportbelt (4) runs over two pulleys and each <strong>en</strong>d is connected tothe connector bracket (5). The connector bracket is connectedto two bearing blocks (6) that ride on the recirculating ballbearingrail (7) that is mounted in the guide cylinder (8). Thecarriage (9) is mounted to the connector bracket and the sealstrip (10) runs betwe<strong>en</strong> them. The connector bracket lifts theseal as the carriage moves, while roller wheels (11) in thecarriage push the seal back in place.R2A positioners have no bearing blocks, but instead have rollerwheels for bearing support (as se<strong>en</strong> in the figure below). Fourtrack-roller bearings run on two hard<strong>en</strong>ed and ground steelshafts, pressed into the extrusion.4119510R2A Carriage316 7 821. Drive Train2. Motor3. Transport Pulley4. Transport Belt5. Connector Bracket6. Bearing Blocks7. <strong>Linear</strong> Rail8. Guide Cylinder9. Carriage10. Seal Strip11. Seal RollerRollerBearingsSteel Shaft80K O L L M O R G E N