Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

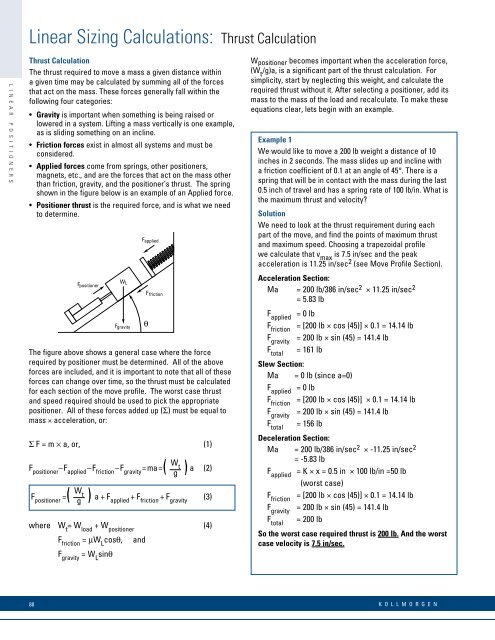

<strong>Linear</strong> Sizing Calculations: Thrust CalculationL I N E A R P O S I T I O N E R SThrust CalculationThe thrust required to move a mass a giv<strong>en</strong> distance withina giv<strong>en</strong> time may be calculated by summing all of the forcesthat act on the mass. These forces g<strong>en</strong>erally fall within thefollowing four categories:• Gravity is important wh<strong>en</strong> something is being raised orlowered in a system. Lifting a mass vertically is one example,as is sliding something on an incline.• Friction forces exist in almost all systems and must beconsidered.• Applied forces come from springs, other positioners,magnets, etc., and are the forces that act on the mass otherthan friction, gravity, and the positioner’s thrust. The springshown in the figure below is an example of an Applied force.• Positioner thrust is the required force, and is what we needto determine.F positionerW LF frictionThe figure above shows a g<strong>en</strong>eral case where the forcerequired by positioner must be determined. All of the aboveforces are included, and it is important to note that all of theseforces can change over time, so the thrust must be calculatedfor each section of the move profile. The worst case thrustand speed required should be used to pick the appropriatepositioner. All of these forces added up (Σ) must be equal tomass × acceleration, or:Σ F = m × a, or, (1)W( t)F positioner–F applied–F friction–F gravity=ma= a (2)g( )WF positioner= tga+F applied+ F friction+ F gravity(3)where W t = W load+ W positioner(4)F friction= µW L cosθ,F gravity= W L sinθF gravityandF appliedW positioner becomes important wh<strong>en</strong> the acceleration force,(W t /g)a, is a significant part of the thrust calculation. Forsimplicity, start by neglecting this weight, and calculate therequired thrust without it. After selecting a positioner, add itsmass to the mass of the load and recalculate. To make theseequations clear, lets begin with an example.Example 1We would like to move a 200 lb weight a distance of 10inches in 2 seconds. The mass slides up and incline witha friction coeffici<strong>en</strong>t of 0.1 at an angle of 45°. There is aspring that will be in contact with the mass during the last0.5 inch of travel and has a spring rate of 100 lb/in. What isthe maximum thrust and velocity?SolutionWe need to look at the thrust requirem<strong>en</strong>t during eachpart of the move, and find the points of maximum thrustand maximum speed. Choosing a trapezoidal profilewe calculate that v max is 7.5 in/sec and the peakacceleration is 11.25 in/sec 2 (see Move Profile Section).Acceleration Section:Ma = 200 lb/386 in/sec 2 × 11.25 in/sec 2= 5.83 lbF applied = 0 lbF friction = [200 lb × cos (45)] × 0.1 = 14.14 lbF gravity = 200 lb × sin (45) = 141.4 lbF total = 161 lbSlew Section:Ma = 0 lb (since a=0)F applied = 0 lbF friction = [200 lb × cos (45)] × 0.1 = 14.14 lbF gravity = 200 lb × sin (45) = 141.4 lbF total = 156 lbDeceleration Section:Ma = 200 lb/386 in/sec 2 × -11.25 in/sec 2= -5.83 lbF applied = K × x = 0.5 in × 100 lb/in =50 lb(worst case)F friction = [200 lb × cos (45)] × 0.1 = 14.14 lbF gravity = 200 lb × sin (45) = 141.4 lbF total = 200 lbSo the worst case required thrust is 200 lb. And the worstcase velocity is 7.5 in/sec.88K O L L M O R G E N