Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

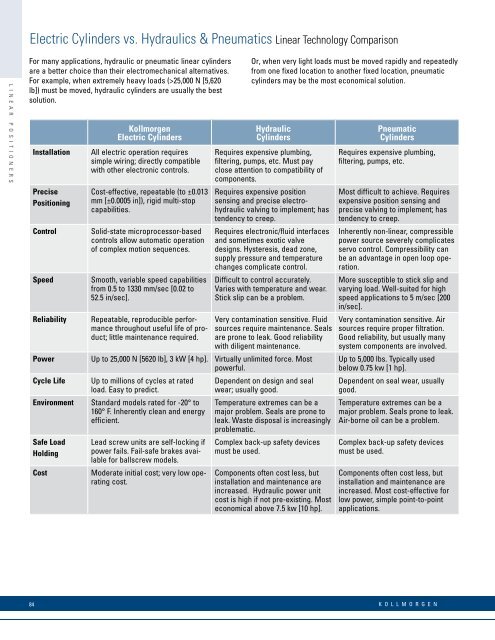

Electric Cylinders vs. Hydraulics & Pneumatics <strong>Linear</strong> Technology ComparisonL I N E A R P O S I T I O N E R SFor many applications, hydraulic or pneumatic linear cylindersare a better choice than their electromechanical alternatives.For example, wh<strong>en</strong> extremely heavy loads (>25,000 N [5,620lb]) must be moved, hydraulic cylinders are usually the bestsolution.InstallationPrecisePositioningControlSpeedReliabilityPowerCycle LifeEnvironm<strong>en</strong>tSafe LoadHoldingCostKollmorg<strong>en</strong>Electric CylindersAll electric operation requiressimple wiring; directly compatiblewith other electronic controls.Cost-effective, repeatable (to ±0.013mm [±0.0005 in]), rigid multi-stopcapabilities.Solid-state microprocessor-basedcontrols allow automatic operationof complex motion sequ<strong>en</strong>ces.Smooth, variable speed capabilitiesfrom 0.5 to 1330 mm/sec [0.02 to52.5 in/sec].Repeatable, reproducible performancethroughout useful life of product;little maint<strong>en</strong>ance required.Or, wh<strong>en</strong> very light loads must be moved rapidly and repeatedlyfrom one fixed location to another fixed location, pneumaticcylinders may be the most economical solution.HydraulicCylindersRequires exp<strong>en</strong>sive plumbing,filtering, pumps, etc. Must payclose att<strong>en</strong>tion to compatibility ofcompon<strong>en</strong>ts.Requires exp<strong>en</strong>sive positions<strong>en</strong>sing and precise electrohydraulicvalving to implem<strong>en</strong>t; hast<strong>en</strong>d<strong>en</strong>cy to creep.Requires electronic/fluid interfacesand sometimes exotic valvedesigns. Hysteresis, dead zone,supply pressure and temperaturechanges complicate control.Difficult to control accurately.Varies with temperature and wear.Stick slip can be a problem.Very contamination s<strong>en</strong>sitive. Fluidsources require maint<strong>en</strong>ance. Sealsare prone to leak. Good reliabilitywith dilig<strong>en</strong>t maint<strong>en</strong>ance.Up to 25,000 N [5620 lb], 3 kW [4 hp]. Virtually unlimited force. Mostpowerful.Up to millions of cycles at ratedload. Easy to predict.Standard models rated for -20° to160° F. Inher<strong>en</strong>tly clean and <strong>en</strong>ergyeffici<strong>en</strong>t.Lead screw units are self-locking ifpower fails. Fail-safe brakes availablefor ballscrew models.Moderate initial cost; very low operatingcost.Dep<strong>en</strong>d<strong>en</strong>t on design and sealwear; usually good.Temperature extremes can be amajor problem. Seals are prone toleak. Waste disposal is increasinglyproblematic.Complex back-up safety devicesmust be used.Compon<strong>en</strong>ts oft<strong>en</strong> cost less, butinstallation and maint<strong>en</strong>ance areincreased. Hydraulic power unitcost is high if not pre-existing. Mosteconomical above 7.5 kw [10 hp].PneumaticCylindersRequires exp<strong>en</strong>sive plumbing,filtering, pumps, etc.Most difficult to achieve. Requiresexp<strong>en</strong>sive position s<strong>en</strong>sing andprecise valving to implem<strong>en</strong>t; hast<strong>en</strong>d<strong>en</strong>cy to creep.Inher<strong>en</strong>tly non-linear, compressiblepower source severely complicatesservo control. Compressibility canbe an advantage in op<strong>en</strong> loop operation.More susceptible to stick slip andvarying load. Well-suited for highspeed applications to 5 m/sec [200in/sec].Very contamination s<strong>en</strong>sitive. Airsources require proper filtration.Good reliability, but usually manysystem compon<strong>en</strong>ts are involved.Up to 5,000 lbs. Typically usedbelow 0.75 kw [1 hp].Dep<strong>en</strong>d<strong>en</strong>t on seal wear, usuallygood.Temperature extremes can be amajor problem. Seals prone to leak.Air-borne oil can be a problem.Complex back-up safety devicesmust be used.Compon<strong>en</strong>ts oft<strong>en</strong> cost less, butinstallation and maint<strong>en</strong>ance areincreased. Most cost-effective forlow power, simple point-to-pointapplications.84K O L L M O R G E N