Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

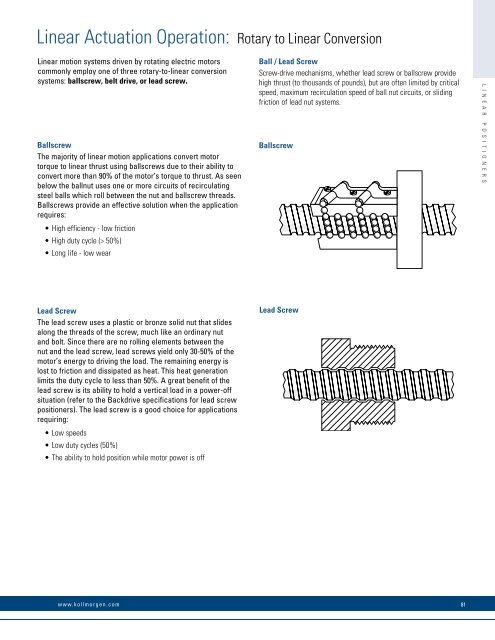

<strong>Linear</strong> Actuation Operation: Rotary to <strong>Linear</strong> Conversion<strong>Linear</strong> motion systems driv<strong>en</strong> by rotating electric motorscommonly employ one of three rotary-to-linear conversionsystems: ballscrew, belt drive, or lead screw.BallscrewThe majority of linear motion applications convert motortorque to linear thrust using ballscrews due to their ability toconvert more than 90% of the motor’s torque to thrust. As se<strong>en</strong>below the ballnut uses one or more circuits of recirculatingsteel balls which roll betwe<strong>en</strong> the nut and ballscrew threads.Ballscrews provide an effective solution wh<strong>en</strong> the applicationrequires:• High effici<strong>en</strong>cy - low friction• High duty cycle (> 50%)• Long life - low wearBall / Lead ScrewScrew-drive mechanisms, whether lead screw or ballscrew providehigh thrust (to thousands of pounds), but are oft<strong>en</strong> limited by criticalspeed, maximum recirculation speed of ball nut circuits, or slidingfriction of lead nut systems.BallscrewL I N E A R P O S I T I O N E R SLead ScrewThe lead screw uses a plastic or bronze solid nut that slidesalong the threads of the screw, much like an ordinary nutand bolt. Since there are no rolling elem<strong>en</strong>ts betwe<strong>en</strong> th<strong>en</strong>ut and the lead screw, lead screws yield only 30-50% of themotor’s <strong>en</strong>ergy to driving the load. The remaining <strong>en</strong>ergy islost to friction and dissipated as heat. This heat g<strong>en</strong>erationlimits the duty cycle to less than 50%. A great b<strong>en</strong>efit of thelead screw is its ability to hold a vertical load in a power-offsituation (refer to the Backdrive specifications for lead screwpositioners). The lead screw is a good choice for applicationsrequiring:• Low speeds• Low duty cycles (50%)• The ability to hold position while motor power is offLead Screwwww.kollmorg<strong>en</strong>.com81