Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

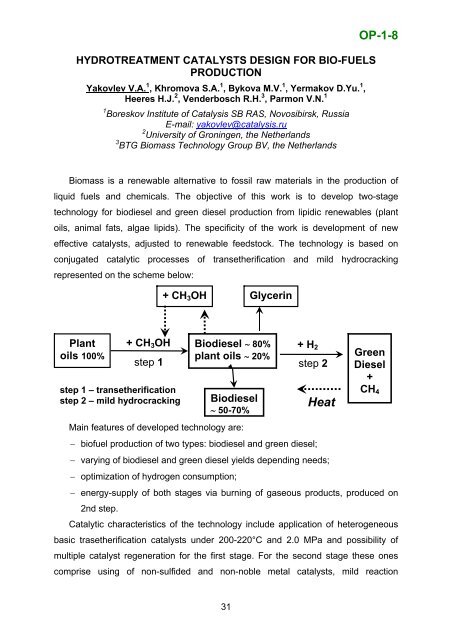

HYDROTREATMENT CATALYSTS DESIGN FOR BIO-FUELSPRODUCTIONYakovlev V.A. 1 , Khromova S.A. 1 , Bykova M.V. 1 , Yermakov D.Yu. 1 ,Heeres H.J. 2 , Venderbosch R.H. 3 , Parmon V.N. 11 <strong>Boreskov</strong> <strong>Institute</strong> <strong>of</strong> <strong>Catalysis</strong> <strong>SB</strong> <strong>RAS</strong>, <strong>Novosibirsk</strong>, <strong>Russia</strong>E-mail: yakovlev@catalysis.ru2 University <strong>of</strong> Groningen, the Netherlands3 BTG Biomass Technology Group BV, the NetherlandsOP-1-8Biomass is a renewable alternative to fossil raw materials in the production <strong>of</strong>liquid fuels and chemicals. The objective <strong>of</strong> this work is to develop two-stagetechnology for biodiesel and green diesel production from lipidic renewables (plantoils, animal fats, algae lipids). The specificity <strong>of</strong> the work is development <strong>of</strong> neweffective catalysts, adjusted to renewable feedstock. The technology is based onconjugated catalytic processes <strong>of</strong> transetherification and mild hydrocrackingrepresented on the scheme below:+ CH 3 OH GlycerinPlantoils 100%step 1 – transetherificationstep 2 – mild hydrocracking+ CH 3 OH Biodiesel ∼ 80% + H 2step 1plant oils ∼ 20%step 2Biodiesel∼ 50-70%Main features <strong>of</strong> developed technology are:− bi<strong>of</strong>uel production <strong>of</strong> two types: biodiesel and green diesel;− varying <strong>of</strong> biodiesel and green diesel yields depending needs;− optimization <strong>of</strong> hydrogen consumption;HeatGreenDiesel+CH 4− energy-supply <strong>of</strong> both stages via burning <strong>of</strong> gaseous products, produced on2nd step.Catalytic characteristics <strong>of</strong> the technology include application <strong>of</strong> heterogeneousbasic trasetherification catalysts under 200-220°C and 2.0 MPa and possibility <strong>of</strong>multiple catalyst regeneration for the first stage. For the second stage these onescomprise using <strong>of</strong> non-sulfided and non-noble metal catalysts, mild reaction31