Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

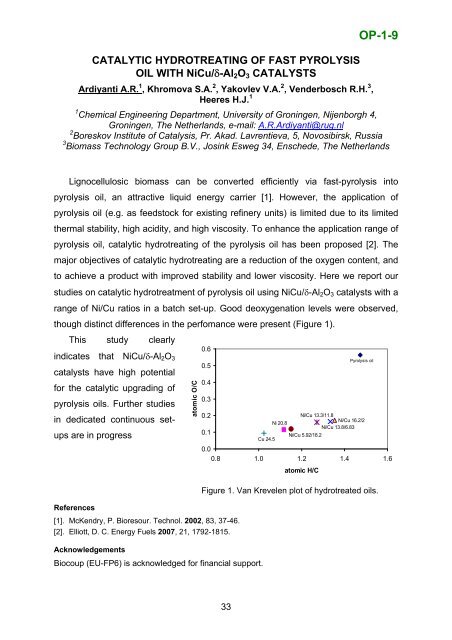

CATALYTIC HYDROTREATING OF FAST PYROLYSISOIL WITH NiCu/δ-Al 2 O 3 CATALYSTSArdiyanti A.R. 1 , Khromova S.A. 2 , Yakovlev V.A. 2 , Venderbosch R.H. 3 ,Heeres H.J. 1OP-1-91 Chemical Engineering Department, University <strong>of</strong> Groningen, Nijenborgh 4,Groningen, The Netherlands, e-mail: A.R.Ardiyanti@rug.nl2 <strong>Boreskov</strong> <strong>Institute</strong> <strong>of</strong> <strong>Catalysis</strong>, Pr. Akad. Lavrentieva, 5, <strong>Novosibirsk</strong>, <strong>Russia</strong>3 Biomass Technology Group B.V., Josink Esweg 34, Enschede, The NetherlandsLignocellulosic biomass can be converted efficiently via fast-pyrolysis intopyrolysis oil, an attractive liquid energy carrier [1]. However, the application <strong>of</strong>pyrolysis oil (e.g. as feedstock for existing refinery units) is limited due to its limitedthermal stability, high acidity, and high viscosity. To enhance the application range <strong>of</strong>pyrolysis oil, catalytic hydrotreating <strong>of</strong> the pyrolysis oil has been proposed [2]. Themajor objectives <strong>of</strong> catalytic hydrotreating are a reduction <strong>of</strong> the oxygen content, andto achieve a product with improved stability and lower viscosity. Here we report ourstudies on catalytic hydrotreatment <strong>of</strong> pyrolysis oil using NiCu/δ-Al 2 O 3 catalysts with arange <strong>of</strong> Ni/Cu ratios in a batch set-up. Good deoxygenation levels were observed,though distinct differences in the perfomance were present (Figure 1).This study clearlyindicates that NiCu/δ-Al 2 O 3catalysts have high potentialfor the catalytic upgrading <strong>of</strong>pyrolysis oils. Further studiesin dedicated continuous setupsare in progressatomic O/CReferences[1]. McKendry, P. Bioresour. Technol. 2002, 83, 37-46.[2]. Elliott, D. C. Energy Fuels 2007, 21, 1792-1815.AcknowledgementsBiocoup (EU-FP6) is acknowledged for financial support.0.60.50.40.30.20.1Pyrolysis oilNi/Cu 13.3/11.8Ni 20.8Ni/Cu 16.2/2Ni/Cu 13.8/6.83Cu 24.5Ni/Cu 5.92/18.20.00.8 1.0 1.2 1.4 1.6atomic H/CFigure 1. Van Krevelen plot <strong>of</strong> hydrotreated oils.33