Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

Boreskov Institute of Catalysis SB RAS, Novosibirsk, Russia

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

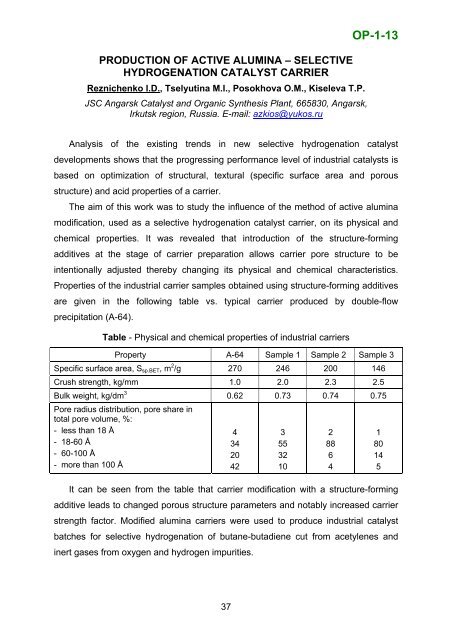

PRODUCTION OF ACTIVE ALUMINA – SELECTIVEHYDROGENATION CATALYST CARRIERReznichenko I.D., Tselyutina M.I., Posokhova O.M., Kiseleva T.P.JSC Angarsk Catalyst and Organic Synthesis Plant, 665830, Angarsk,Irkutsk region, <strong>Russia</strong>. E-mail: azkios@yukos.ruOP-1-13Analysis <strong>of</strong> the existing trends in new selective hydrogenation catalystdevelopments shows that the progressing performance level <strong>of</strong> industrial catalysts isbased on optimization <strong>of</strong> structural, textural (specific surface area and porousstructure) and acid properties <strong>of</strong> a carrier.The aim <strong>of</strong> this work was to study the influence <strong>of</strong> the method <strong>of</strong> active aluminamodification, used as a selective hydrogenation catalyst carrier, on its physical andchemical properties. It was revealed that introduction <strong>of</strong> the structure-formingadditives at the stage <strong>of</strong> carrier preparation allows carrier pore structure to beintentionally adjusted thereby changing its physical and chemical characteristics.Properties <strong>of</strong> the industrial carrier samples obtained using structure-forming additivesare given in the following table vs. typical carrier produced by double-flowprecipitation (А-64).Table - Physical and chemical properties <strong>of</strong> industrial carriersProperty А-64 Sample 1 Sample 2 Sample 3Specific surface area, S sp.BET , m 2 /g 270 246 200 146Crush strength, kg/mm 1.0 2.0 2.3 2.5Bulk weight, kg/dm 3 0.62 0.73 0.74 0.75Pore radius distribution, pore share intotal pore volume, %:- less than 18 Å- 18-60 Å- 60-100 Å- more than 100 Å4342042It can be seen from the table that carrier modification with a structure-formingadditive leads to changed porous structure parameters and notably increased carrierstrength factor. Modified alumina carriers were used to produce industrial catalystbatches for selective hydrogenation <strong>of</strong> butane-butadiene cut from acetylenes andinert gases from oxygen and hydrogen impurities.35532102886418014537