Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

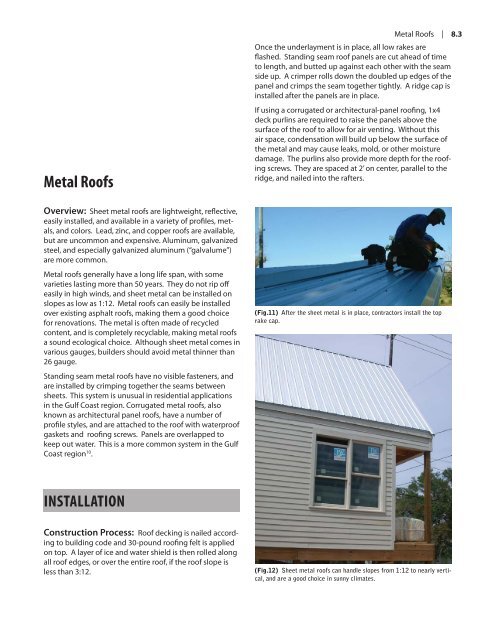

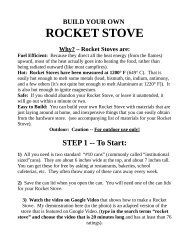

Metal RoofsMetal Roofs | 8.3Once the underlayment is in place, all low rakes areflashed. Standing seam roof panels are cut ahead of timeto length, and butted up against each other with the seamside up. A crimper rolls down the doubled up edges of thepanel and crimps the seam together tightly. A ridge cap isinstalled after the panels are in place.If using a corrugated or architectural-panel roofing, 1x4deck purlins are required to raise the panels above thesurface of the roof to allow for air venting. Without thisair space, condensation will build up below the surface ofthe metal and may cause leaks, mold, or other moisturedamage. The purlins also provide more depth for the roofingscrews. They are spaced at 2’ on center, parallel to theridge, and nailed into the rafters.Overview: Sheet metal roofs are lightweight, reflective,easily installed, and available in a variety of profiles, metals,and colors. Lead, zinc, and copper roofs are available,but are uncommon and expensive. Aluminum, galvanizedsteel, and especially galvanized aluminum (“galvalume”)are more common.Metal roofs generally have a long life span, with somevarieties lasting more than 50 years. They do not rip offeasily in high winds, and sheet metal can be installed onslopes as low as 1:12. Metal roofs can easily be installedover existing asphalt roofs, making them a good choicefor renovations. The metal is often made of recycledcontent, and is completely recyclable, making metal roofsa sound ecological choice. Although sheet metal comes invarious gauges, builders should avoid metal thinner than26 gauge.Standing seam metal roofs have no visible fasteners, andare installed by crimping together the seams betweensheets. This system is unusual in residential applicationsin the Gulf Coast region. Corrugated metal roofs, alsoknown as architectural panel roofs, have a number ofprofile styles, and are attached to the roof with waterproofgaskets and roofing screws. Panels are overlapped tokeep out water. This is a more common system in the GulfCoast region 10 .(Fig.11) After the sheet metal is in place, contractors install the toprake cap.INSTALLATION<strong>Construction</strong> Process: Roof decking is nailed accordingto building code and 30-pound roofing felt is appliedon top. A layer of ice and water shield is then rolled alongall roof edges, or over the entire roof, if the roof slope isless than 3:12.(Fig.12) Sheet metal roofs can handle slopes from 1:12 to nearly vertical,and are a good choice in sunny climates.