Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

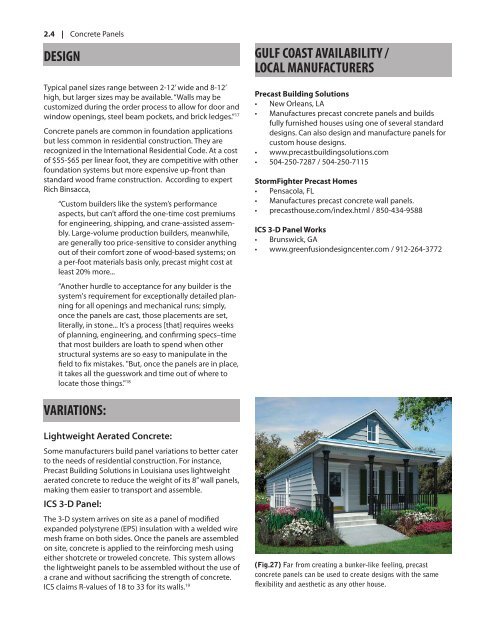

2.4 | Concrete PanelsDESIGNGULF COAST AVAILABILITY /LOCAL MANUFACTURERSTypical panel sizes range between 2-12’ wide and 8-12’high, but larger sizes may be available. “Walls may bePrecast Building Solutionscustomized during the order process to allow for door and • New Orleans, LAwindow openings, steel beam pockets, and brick ledges.” 17 •Concrete panels are common in foundation applicationsbut less common in residential construction. They arerecognized in the International Residential Code. At a cost • www.precastbuildingsolutions.comof $55-$65 per linear foot, they are competitive with other • 504-250-7287 / 504-250-7115foundation systems but more expensive up-front thanstandard wood frame construction. According to expert StormFighter Precast HomesRich Binsacca,• Pensacola, FL“Custom builders like the system’s performance•aspects, but can’t afford the one-time cost premiums •for engineering, shipping, and crane-assisted assembly.Large-volume production builders, meanwhile, ICS 3-D Panel Worksare generally too price-sensitive to consider anything • Brunswick, GAout of their comfort zone of wood-based systems; on •a per-foot materials basis only, precast might cost atleast 20% more...“Another hurdle to acceptance for any builder is thesystem's requirement for exceptionally detailed planningfor all openings and mechanical runs; simply,once the panels are cast, those placements are set,literally, in stone... It's a process [that] requires weeksof planning, engineering, and confirming specs–timethat most builders are loath to spend when otherstructural systems are so easy to manipulate in thefield to fix mistakes. "But, once the panels are in place,it takes all the guesswork and time out of where tolocate those things." 18VARIATIONS:Lightweight Aerated Concrete:Some manufacturers build panel variations to better caterto the needs of residential construction. For instance,Precast Building Solutions in Louisiana uses lightweightaerated concrete to reduce the weight of its 8” wall panels,making them easier to transport and assemble.ICS 3-D Panel:The 3-D system arrives on site as a panel of modifiedexpanded polystyrene (EPS) insulation with a welded wiremesh frame on both sides. Once the panels are assembledon site, concrete is applied to the reinforcing mesh usingeither shotcrete or troweled concrete. This system allowsthe lightweight panels to be assembled without the use ofa crane and without sacrificing the strength of concrete.ICS claims R-values of 18 to 33 for its walls. 19Manufactures precast concrete panels and buildsfully furnished houses using one of several standarddesigns. Can also design and manufacture panels forcustom house designs.Manufactures precast concrete wall panels.precasthouse.com/index.html / 850-434-9588www.greenfusiondesigncenter.com / 912-264-3772(Fig.27) Far from creating a bunker-like feeling, precastconcrete panels can be used to create designs with the sameflexibility and aesthetic as any other house.