Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

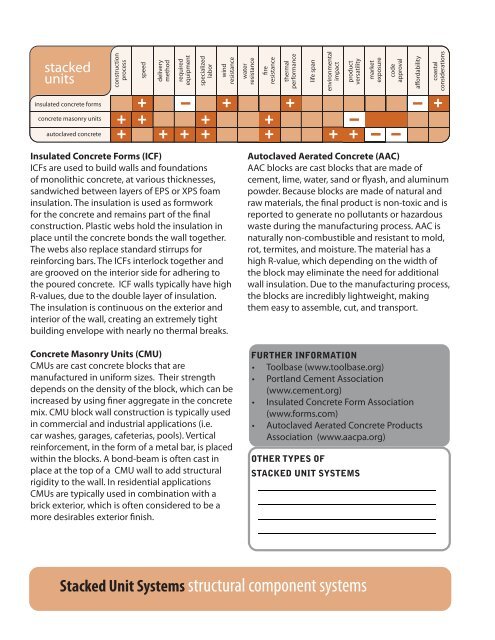

stackedunitsconstructionprocessspeeddeliverymethodrequiredequipmentspecializedlaborwindresistancewaterresistancefireresistancethermalperformancelife spanenvironmentalimpactproductversatilitymarketexposurecodeapprovalaffordabilitycoastalconsiderationsinsulated concrete formsconcrete masonry unitsautoclaved concreteInsulated Concrete Forms (ICF)ICFs are used to build walls and foundationsof monolithic concrete, at various thicknesses,sandwiched between layers of EPS or XPS foaminsulation. The insulation is used as formworkfor the concrete and remains part of the finalconstruction. Plastic webs hold the insulation inplace until the concrete bonds the wall together.The webs also replace standard stirrups forreinforcing bars. The ICFs interlock together andare grooved on the interior side for adhering tothe poured concrete. ICF walls typically have highR-values, due to the double layer of insulation.The insulation is continuous on the exterior andinterior of the wall, creating an extremely tightbuilding envelope with nearly no thermal breaks.Concrete Masonry Units (CMU)CMUs are cast concrete blocks that aremanufactured in uniform sizes. Their strengthdepends on the density of the block, which can beincreased by using finer aggregate in the concretemix. CMU block wall construction is typically usedin commercial and industrial applications (i.e.car washes, garages, cafeterias, pools). Verticalreinforcement, in the form of a metal bar, is placedwithin the blocks. A bond-beam is often cast inplace at the top of a CMU wall to add structuralrigidity to the wall. In residential applicationsCMUs are typically used in combination with abrick exterior, which is often considered to be amore desirables exterior finish.Autoclaved Aerated Concrete (AAC)AAC blocks are cast blocks that are made ofcement, lime, water, sand or flyash, and aluminumpowder. Because blocks are made of natural andraw materials, the final product is non-toxic and isreported to generate no pollutants or hazardouswaste during the manufacturing process. AAC isnaturally non-combustible and resistant to mold,rot, termites, and moisture. The material has ahigh R-value, which depending on the width ofthe block may eliminate the need for additionalwall insulation. Due to the manufacturing process,the blocks are incredibly lightweight, makingthem easy to assemble, cut, and transport.FURTHER INFORMATION• Toolbase (www.toolbase.org)• Portland Cement Association(www.cement.org)• Insulated Concrete Form Association(www.forms.com)• Autoclaved Aerated Concrete ProductsAssociation (www.aacpa.org)OTHER TYPES OFSTACKED UNIT SYSTEMSStacked Unit Systems structural component systems