Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

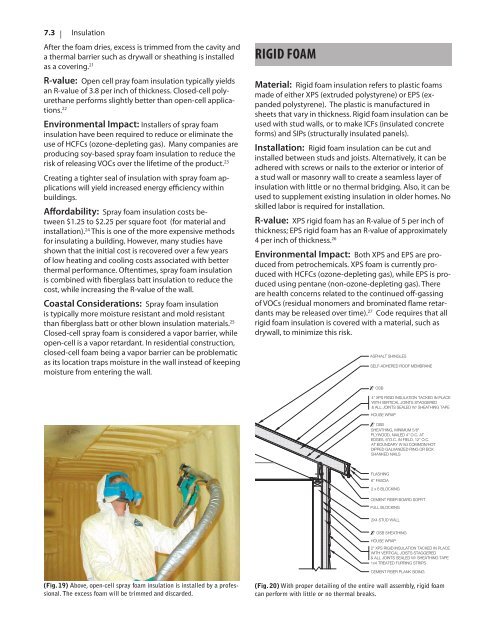

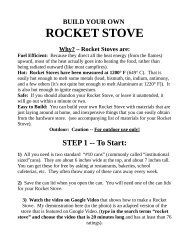

7.3 | InsulationAfter the foam dries, excess is trimmed from the cavity anda thermal barrier such as drywall or sheathing is installedas a covering. 21R-value: Open cell pray foam insulation typically yieldsan R-value of 3.8 per inch of thickness. Closed-cell polyurethaneperforms slightly better than open-cell applications.22Environmental Impact: Installers of spray foaminsulation have been required to reduce or eliminate theuse of HCFCs (ozone-depleting gas). Many companies areproducing soy-based spray foam insulation to reduce therisk of releasing VOCs over the lifetime of the product. 23Creating a tighter seal of insulation with spray foam applicationswill yield increased energy efficiency withinbuildings.Affordability: Spray foam insulation costs between$1.25 to $2.25 per square foot (for material andinstallation). 24 This is one of the more expensive methodsfor insulating a building. However, many studies haveshown that the initial cost is recovered over a few yearsof low heating and cooling costs associated with betterthermal performance. Oftentimes, spray foam insulationis combined with fiberglass batt insulation to reduce thecost, while increasing the R-value of the wall.Coastal Considerations: Spray foam insulationis typically more moisture resistant and mold resistantthan fiberglass batt or other blown insulation materials. 25Closed-cell spray foam is considered a vapor barrier, whileopen-cell is a vapor retardant. In residential construction,closed-cell foam being a vapor barrier can be problematicas its location traps moisture in the wall instead of keepingmoisture from entering the wall.RIGID FOAMMaterial: Rigid foam insulation refers to plastic foamsmade of either XPS (extruded polystyrene) or EPS (expandedpolystyrene). The plastic is manufactured insheets that vary in thickness. Rigid foam insulation can beused with stud walls, or to make ICFs (insulated concreteforms) and SIPs (structurally insulated panels).Installation: Rigid foam insulation can be cut andinstalled between studs and joists. <strong>Alternative</strong>ly, it can beadhered with screws or nails to the exterior or interior ofa stud wall or masonry wall to create a seamless layer ofinsulation with little or no thermal bridging. Also, it can beused to supplement existing insulation in older homes. Noskilled labor is required for installation.R-value: XPS rigid foam has an R-value of 5 per inch ofthickness; EPS rigid foam has an R-value of approximately4 per inch of thickness. 26Environmental Impact: Both XPS and EPS are producedfrom petrochemicals. XPS foam is currently producedwith HCFCs (ozone-depleting gas), while EPS is producedusing pentane (non-ozone-depleting gas). Thereare health concerns related to the continued off-gassingof VOCs (residual monomers and brominated flame retardantsmay be released over time). 27 Code requires that allrigid foam insulation is covered with a material, such asdrywall, to minimize this risk.(Fig. 19) Above, open-cell spray foam insulation is installed by a professional.The excess foam will be trimmed and discarded.(Fig. 20) With proper detailing of the entire wall assembly, rigid foamcan perform with little or no thermal breaks.