Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

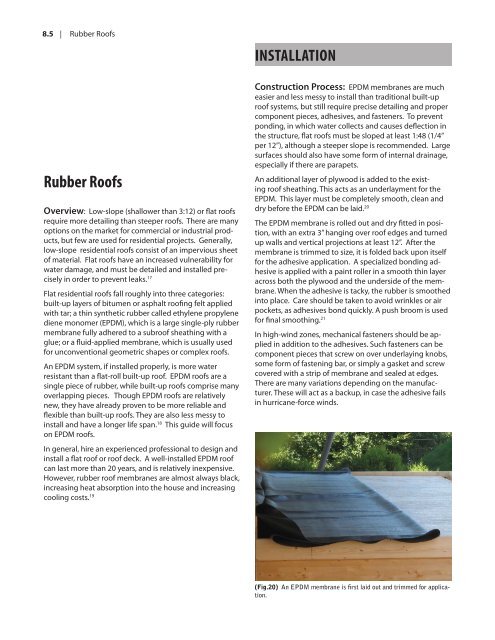

8.5 | Rubber RoofsINSTALLATIONRubber RoofsOverview: Low-slope (shallower than 3:12) or flat roofsrequire more detailing than steeper roofs. There are manyoptions on the market for commercial or industrial products,but few are used for residential projects. Generally,low-slope residential roofs consist of an impervious sheetof material. Flat roofs have an increased vulnerability forwater damage, and must be detailed and installed preciselyin order to prevent leaks. 17Flat residential roofs fall roughly into three categories:built-up layers of bitumen or asphalt roofing felt appliedwith tar; a thin synthetic rubber called ethylene propylenediene monomer (EPDM), which is a large single-ply rubbermembrane fully adhered to a subroof sheathing with aglue; or a fluid-applied membrane, which is usually usedfor unconventional geometric shapes or complex roofs.An EPDM system, if installed properly, is more waterresistant than a flat-roll built-up roof. EPDM roofs are asingle piece of rubber, while built-up roofs comprise manyoverlapping pieces. Though EPDM roofs are relativelynew, they have already proven to be more reliable andflexible than built-up roofs. They are also less messy toinstall and have a longer life span. 18 This guide will focuson EPDM roofs.In general, hire an experienced professional to design andinstall a flat roof or roof deck. A well-installed EPDM roofcan last more than 20 years, and is relatively inexpensive.However, rubber roof membranes are almost always black,increasing heat absorption into the house and increasingcooling costs. 19<strong>Construction</strong> Process: EPDM membranes are mucheasier and less messy to install than traditional built-uproof systems, but still require precise detailing and propercomponent pieces, adhesives, and fasteners. To preventponding, in which water collects and causes deflection inthe structure, flat roofs must be sloped at least 1:48 (1/4”per 12”), although a steeper slope is recommended. Largesurfaces should also have some form of internal drainage,especially if there are parapets.An additional layer of plywood is added to the existingroof sheathing. This acts as an underlayment for theEPDM. This layer must be completely smooth, clean anddry before the EPDM can be laid. 20The EPDM membrane is rolled out and dry fitted in position,with an extra 3” hanging over roof edges and turnedup walls and vertical projections at least 12”. After themembrane is trimmed to size, it is folded back upon itselffor the adhesive application. A specialized bonding adhesiveis applied with a paint roller in a smooth thin layeracross both the plywood and the underside of the membrane.When the adhesive is tacky, the rubber is smoothedinto place. Care should be taken to avoid wrinkles or airpockets, as adhesives bond quickly. A push broom is usedfor final smoothing. 21In high-wind zones, mechanical fasteners should be appliedin addition to the adhesives. Such fasteners can becomponent pieces that screw on over underlaying knobs,some form of fastening bar, or simply a gasket and screwcovered with a strip of membrane and sealed at edges.There are many variations depending on the manufacturer.These will act as a backup, in case the adhesive failsin hurricane-force winds.(Fig.20) An EPDM membrane is first laid out and trimmed for application.