Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

Alternative Construction Research Guide - GCCDS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

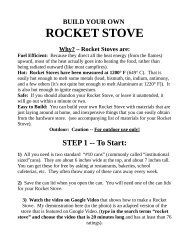

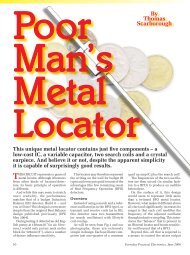

2.2 | Non-Wood SIPsand full construction services are typical examples.Speed of <strong>Construction</strong>: Claims vary from a fifty percentsavings in time (particularly for experienced builders)to no appreciable difference compared to traditional constructiontechniques. Faster construction time and lowerlabor costs may offset higher material costs.Delivery Method: Panels will likely be delivered bytruck. A standard size for many manufacturers is 4ft x 8ft,but panels can be up to 30ft long, depending on the sizeof the truck available for delivery.Required Equipment: Metal or fiber cement 4ft x 8ftpanels can be handled by two people, but larger panelsmay require the use of a crane or forklift. Fiber-reinforcedplastic panels are lighter and in most cases can be assembledby without the use of heavy lifting equipment.Specialized Labor: Workers familiar with typicalconstruction techniques can easily be trained to assemblemany of these systems. Some systems, however, mayrequire additional expertise. In some cases, electrical andplumbing work may require special expertise to install.PERFORMANCEWind Load: Manufacturers of non-wood SIPs claim thatthey offer higher strength and better resistance to windloads than either wood SIPs or standard wood framing. Forinstance, InnoVida claims its panels can withstand windloads up to 186 mph. OceanSafe warrants its system upto 150 mph. The International Residential Code specifiesdesign wind loads of 140 mph in most hurricane-pronecoastal areas. 7,8,9Panels can often be engineered to meet the wind load requiredfor a project. However, wind resistance will dependas much on the connections and configuration of thepanels as it does on the strength of the panels themselves.Additionally, panels that perform well under one type ofload, such as shear (wind load), may perform differentlyunder other types of loads. Consult the manufacturer forstrength information and instructions on correctly installingpanels.Water Resistance: Non-wood structural skins used inSIPs typically display superior water resistance. Stainlesssteel and galvanized steel are waterproof and resistantto corrosion. Fiber cement is highly resistant to moistureabsorption. Fiber-reinforced plastic, which is also usedin boat-building and marine applications, offers the bestwater resistance. It resists algae, fungi, water, and osmosisand has a high level of chemical stability against saltwater. All of these systems offer advantages in flood-proneareas. However, any system can be weakened by improperinstallation.Fire Resistance: Many non-wood systems offer excellentfire resistance. Steel and fiber cement are noncombustiblematerials. When used on the inside of a wall,fiber cement meets the code requirement for a 1/2” firebarrier. In the case of fiber-reinforced plastic, check withthe manufacturer that it does not give off toxic chemicalswhen it burns.EPS and polyurethane foam (PU), the insulation materialsused in many non-wood panels, are not highly flammablematerials. Given enough heat and air, they will burn, butare not prone to spread the fire.Energy / Thermal: Energy and thermal performance issignificantly better than standard wood framing and equalto or better than wood-sheathed SIPs, depending on theinsulation material used. Many manufacturers claim insu-(Fig.15) A worker installs wiring in a house built usingInnoVida fiber-reinforced plastic panels in Dubai, UAE.(Fig.16) Metal SIP corner showing window openings cased outusing galvanized steel channels.